Production line for plastic granulating, mixing and packaging and application method thereof

A production line and mixing technology, applied in the field of plastic granulation, mixing, and packaging production lines, can solve the problems of low production efficiency, high labor participation, large repetitive labor, etc., to reduce labor intensity, automatic operation process, The effect of avoiding product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

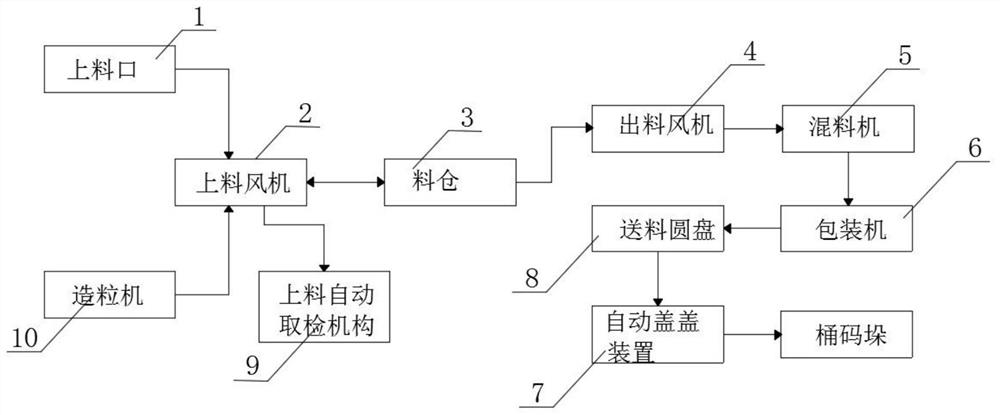

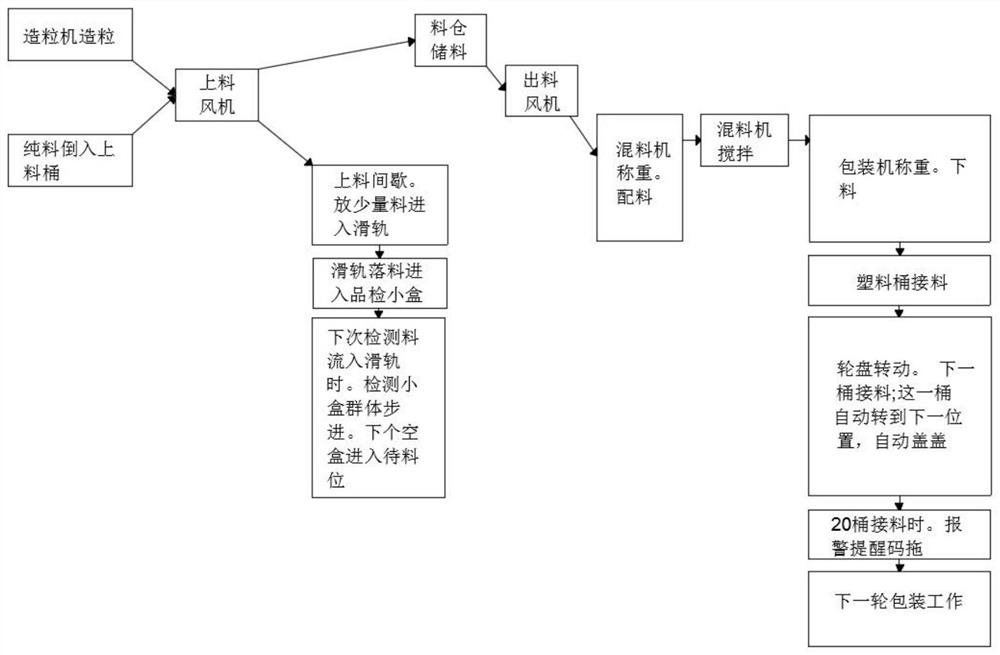

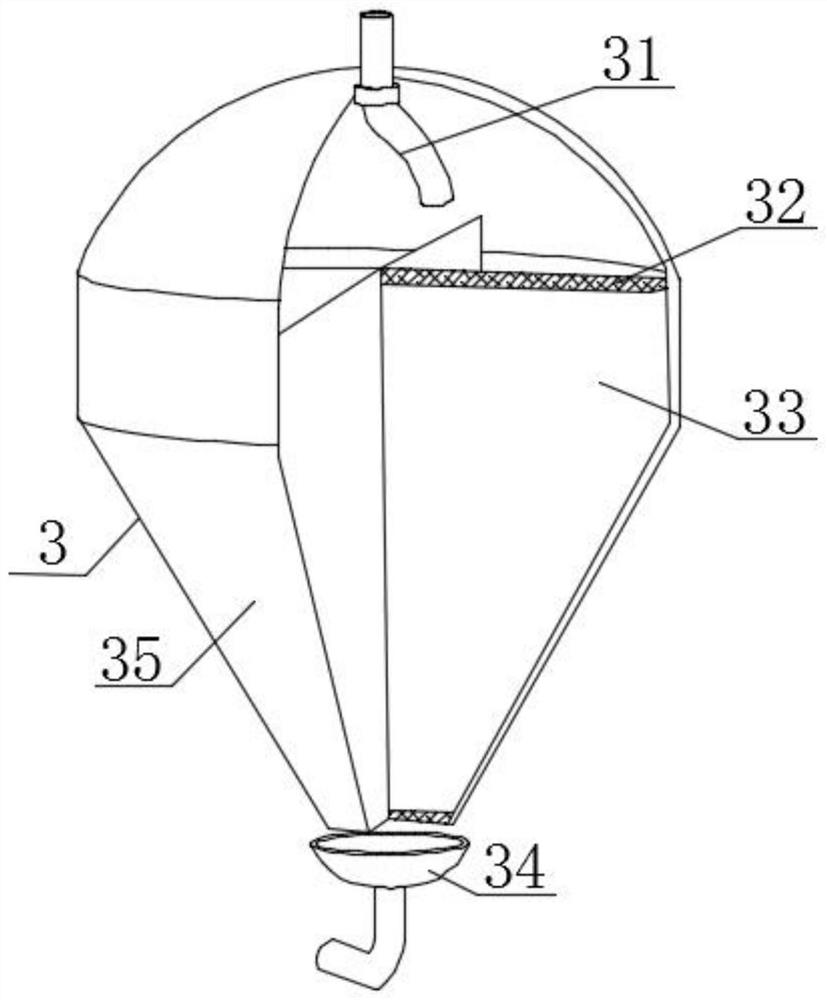

[0025] Such as Figure 1-4 As shown, a production line for plastic granulation, mixing, packaging, comprising a upper fan 2, and the upper left side of the upper fan 2 is connected to the upper mouth 1, the upper left side of the upper fan 2 is located on the upper The lower portion of the inlet 1 is connected to the granulator 10 by the air tube. The upper right side of the upper fan 2 is connected to the air tube, and the upper right side of the upper fan 2 is located at the above automatic examination mechanism. The upper right side of the 9 is connected to the wind tube 3, and the upper right side of the silo 3 is attached to the wind tube, and the right side of the discharge fan 4 is connected to the mixing machine 5, the mixing machine 5. The lower part is connected to the wind tube 6, and the left side of the packaging machine 6 is connected to the feed disc device 8 through the pipe, and the feed disc device 8 is connected to the automatic cover device 7....

Example Embodiment

[0027] Example 2

[0028] Such as Figure 1-4 As shown, a production line for plastic granulation, mixing, packaging, comprising a upper fan 2, and the upper left side of the upper fan 2 is connected to the upper mouth 1, the upper left side of the upper fan 2 is located on the upper The lower portion of the inlet 1 is connected to the granulator 10 by the air tube. The upper right side of the upper fan 2 is connected to the air tube, and the upper right side of the upper fan 2 is located at the above automatic examination mechanism. The upper right side of the 9 is connected to the wind tube 3, and the upper right side of the silo 3 is attached to the wind tube, and the right side of the discharge fan 4 is connected to the mixing machine 5, the mixing machine 5. The lower part is connected to the wind tube 6, and the left side of the packaging machine 6 is connected to the feed disc device 8 through the pipe, and the feed disc device 8 is connected to the automatic cover device 7,...

Example Embodiment

[0030] Example 3

[0031] Such as Figure 1-4 As shown, a production line for plastic granulation, mixing, packaging, comprising a upper fan 2, and the upper left side of the upper fan 2 is connected to the upper mouth 1, the upper left side of the upper fan 2 is located on the upper The lower portion of the inlet 1 is connected to the granulator 10 by the air tube. The upper right side of the upper fan 2 is connected to the air tube, and the upper right side of the upper fan 2 is located at the above automatic examination mechanism. The upper right side of the 9 is connected to the wind tube 3, and the upper right side of the silo 3 is attached to the wind tube, and the right side of the discharge fan 4 is connected to the mixing machine 5, the mixing machine 5. The lower side is connected by a duct, and the left side of the packaging machine 6 is connected to the feed disc device 8 through the pipe, and the feed disc device 8 is connected to the automatic cover device 7, the feed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap