A method for excavating foundation pits with cofferdam enclosure and sloping suitable for deep and thick silt covering layers

A technology of covering layer and cofferdam, which is applied in basic structure engineering, earthmoving machine/shovel, construction, etc. and anti-slip force, reducing settlement and lateral displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

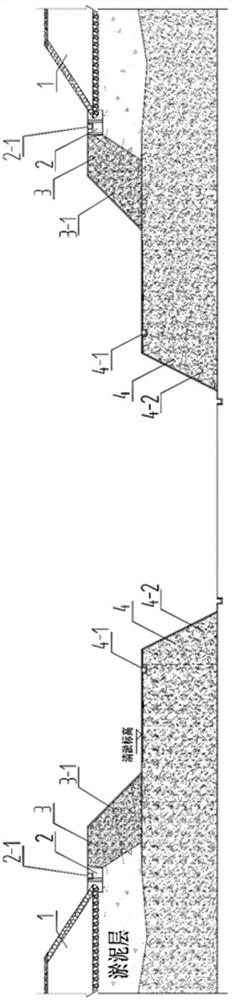

Image

Examples

Embodiment 1

[0053] Embodiment 1, first divide 5 partitions in the two cofferdam bodies 1, first carry out only the reinforcement construction of the 1st partition;

[0054] After the completion of the reinforcement construction in the 1st division, start the reinforcement construction in the 2nd division and the gravel replacement back pressure construction in the 1st division;

[0055] After the completion of the reinforcement construction in the 2nd division, start the reinforcement construction in the 3rd division, the gravel replacement and back pressure construction in the 2nd division and the dredging construction in the 1st division;

[0056] After the reinforcement construction of the 3rd division is completed, start the reinforcement construction of the 4th division, the gravel replacement and back pressure construction of the 3rd division, the dredging construction of the 2nd division, and the stratum excavation construction of the 1st division;

[0057] After the completion of ...

Embodiment 2

[0065] First, divide 10 partitions in the two cofferdam bodies 1,

[0066] Step a: During the excavation of the stratum in the (K-3) subregion, simultaneously start and implement the dredging construction in the (K-2) subregion, the gravel replacement and filling back pressure construction in the (K-1) subregion, and the Reinforcement construction of the K-th zone;

[0067] Step b: After the completion of step a, simultaneously start and implement the stratum excavation construction of the (K-2) subregion, the dredging construction of the (K-1) subregion, the gravel replacement and back pressure construction of the K subregion and the first subregion. (K+1) Reinforcement construction of partitions;

[0068] When K=1, only the reinforcement construction of the 1st partition is carried out; when K=2, after the completion of the reinforcement construction of the 1st partition, the reinforcement construction of the 2nd partition and the gravel replacement and back pressure constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com