Starting and generating integrated gas turbine power generation system

A gas turbine and power generation system technology, applied in the direction of gas turbine devices, electromechanical devices, machines/engines, etc., can solve the problems of long transition time of gas turbines, exhaust pollution, large space occupation, etc., and achieve compact appearance, low operating costs, and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The technical solutions of the present invention will be further described in further detail below in conjunction with specific embodiments. In the description of the invention, the meaning of "multiple" is two or more than one other words unless otherwise stated.

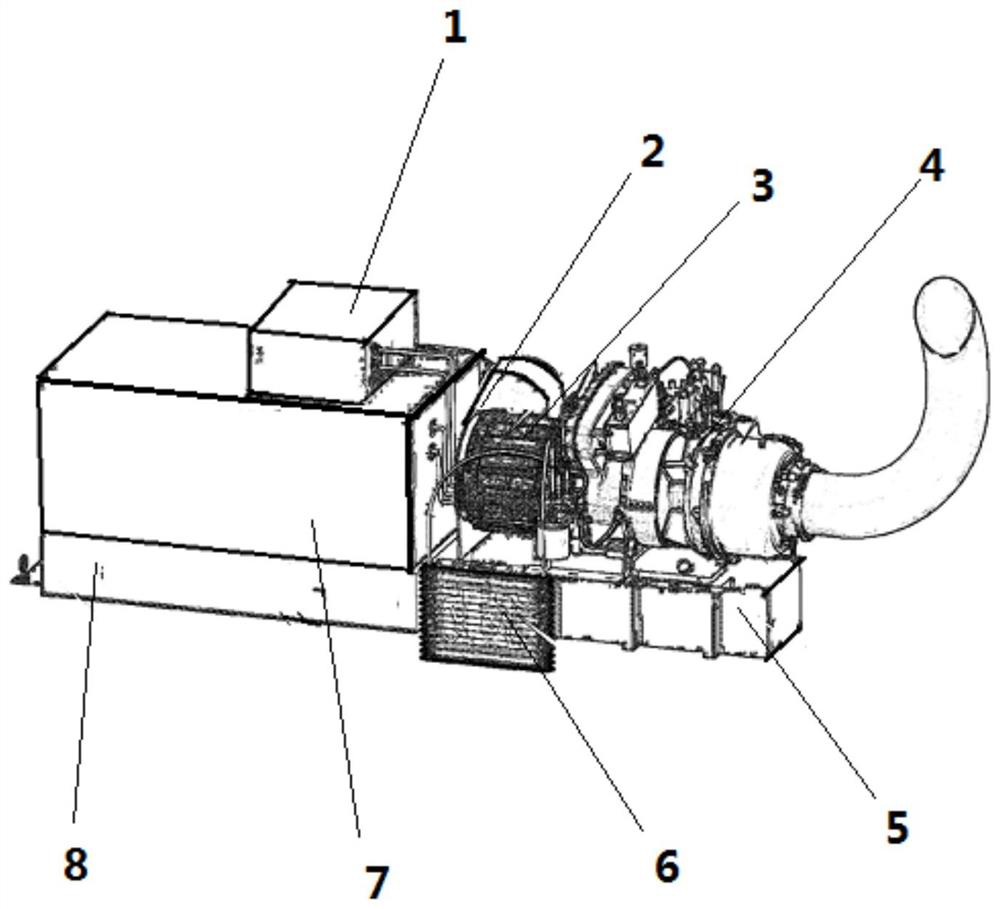

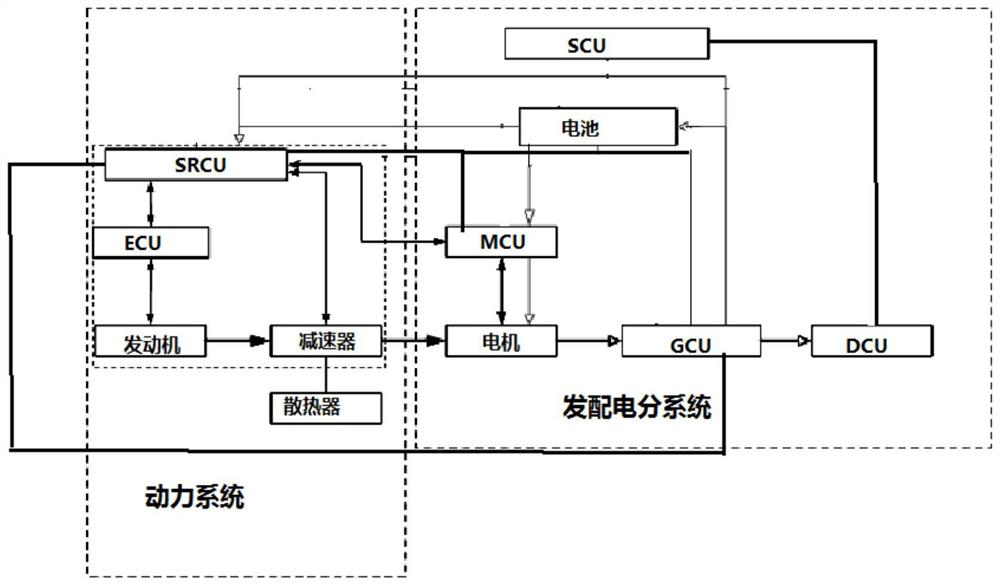

[0028] In the embodiment of the present invention, such as figure 1 with figure 2 As shown, a start-up gas turbine power generation system includes a power division system and an in-power system, the power division system and the transmission system respectively set a power interface and communication interface, respectively, and is implemented by an interconnected interconnection of the power interface. Energy flow, the interaction of the communication interface, the power interface and the communication interface are used to implement flexible connections; the power division system includes engine 4, reducer, ECU and SRCU; the distribution system includes power generation Machines 3, GCU7, DCU, MCU1 and batter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap