A kind of technological method for preparing maleic acid glycol ester

A technology of diol maleate and process method, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as incompatibility, prolong life, reduce equipment corrosion, The effect of increasing the reaction temperature and reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

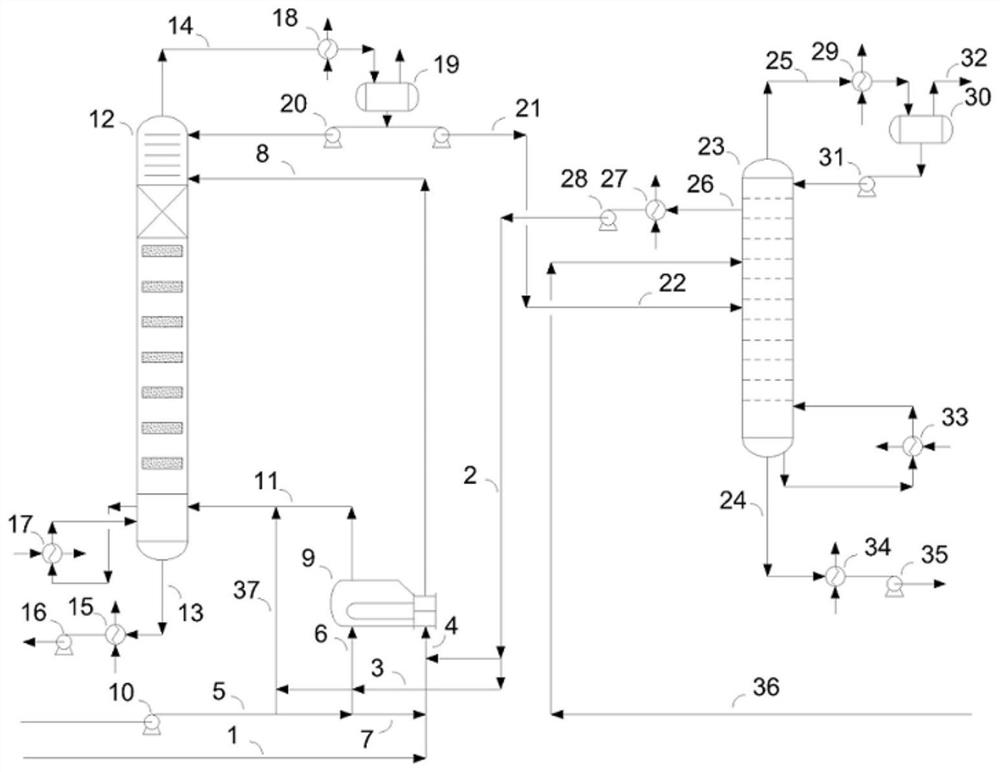

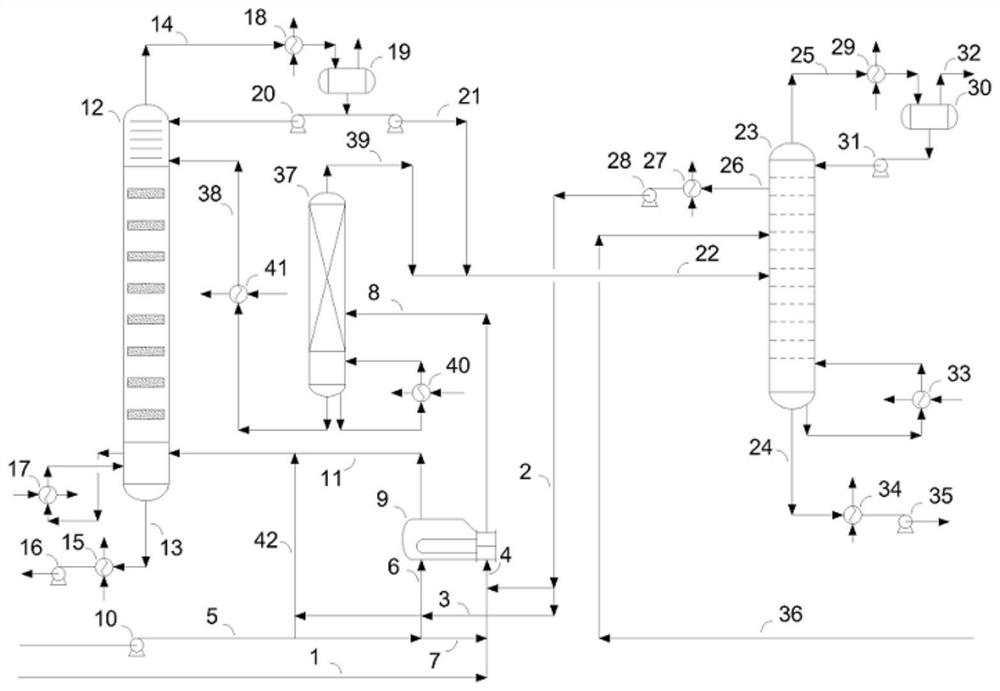

Method used

Image

Examples

Embodiment A1~A5

[0049] Examples A1-A5: Exploration of maleic anhydride / methanol molar ratio

[0050] In a 2.5L autoclave, add 4mol (392g) of maleic anhydride MAH, then add 6mol (192g) of methanol, after three times of 5kg nitrogen replacement, raise the reaction temperature to 110°C and keep stirring, and take samples at intervals , and detected by gas chromatography, after 8 hours of reaction, the composition of each component in the system does not change, which proves that the reaction has reached an equilibrium state. Under the same reaction conditions, the reaction proceeded three times. The difference was that the molar ratio of maleic anhydride and methanol changed from 1:1.2 to 1:1.5, 1:2, 1:2.5 and 1:3 respectively, that is, the added The amount of methanol is 4.8mol (153.6g), 58mol (256g), 10mol (320g) and 12mol (384g) respectively, the reaction process is the same, and finally all reach the equilibrium state, the above different MAH / methanol ratio and the equilibrium composition of...

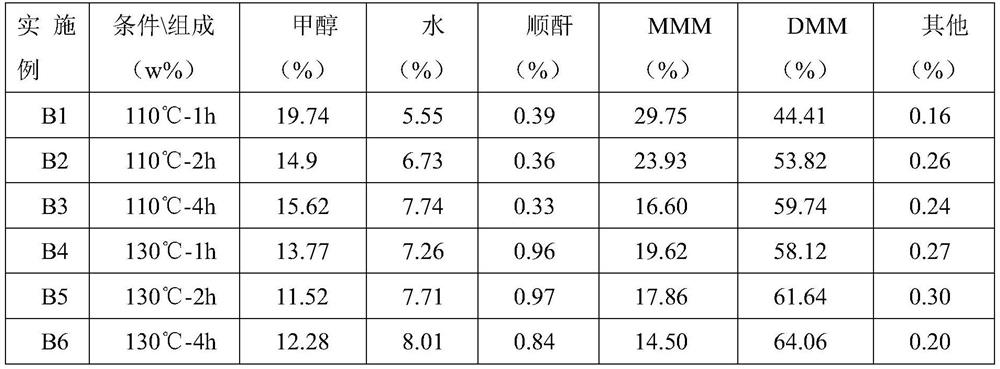

Embodiment B1~B5

[0054] Examples B1-B5: Exploration of the first stage esterification reaction conditions

[0055] The first step of the esterification reaction is carried out in a shell-side Φ108X4 (SS304), tube-side 7 pieces of Φ25X3 (SS316L) tube-and-tube reactors, and the tube-side is filled with Φ5X5 ceramic Raschig rings (bulk density 1.2, pores Rate 0.46), the shell side uses circulating heat transfer oil with a fixed temperature as the heat transfer medium; the maleic anhydride melts and keeps the temperature at 90°C, the pump head and pipeline of the feed pump are kept at 110°C with electric heat tracing; methanol is kept at 50°C, The methanol pump pump head and pipeline are also kept at 50°C; the pressure of the two product collection tanks of the product collection system is maintained at 1.0Mpa in the mode of nitrogen back pressure, so that the reaction can be carried out continuously, and the molar ratio of the maleic anhydride and methanol of the feed is 1: 2.5; the reactions wer...

Embodiment C1

[0058] Embodiment C1: the synthesis of dimethyl maleate DMM

[0059] (1) first-stage esterification reaction: with embodiment B3;

[0060] (2) Flash distillation: 4000 g of the reaction mixture under the condition of 110°C-4h obtained in the previous step is carried out to flash distillation; the used flash distillation column is a continuous feed in the middle, with a total length of one meter and an inner diameter of It is a 25mm glass rectification tower with Φ5 titanium ring wire mesh packing inside. There is a 2500ml three-neck flask at the bottom of the flash rectification tower, which is heated by an oil bath; the entire flash rectification tower is equipped with upper reflux and extraction, The middle feed and the bottom outlet are both fed and discharged by a peristaltic pump equipped with a silicone tube; the entire flash distillation column is operated under a slight positive pressure, and the temperature of the tower body is 80-120 ° C. The three-necked flask at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com