Sandstone gravel C60 low-creep concrete for bridge engineering

A bridge engineering and concrete technology, which is applied in the field of sandstone crushed stone C60 low creep concrete for bridge engineering, can solve the problems of increasing engineering construction cost, limited lithologic selectivity of crushed stone for concrete, and prolonging construction period, and achieves optimization. Microscopic properties, enhancement of shrinkage and creep inhibition, and inhibition of dry shrinkage due to water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

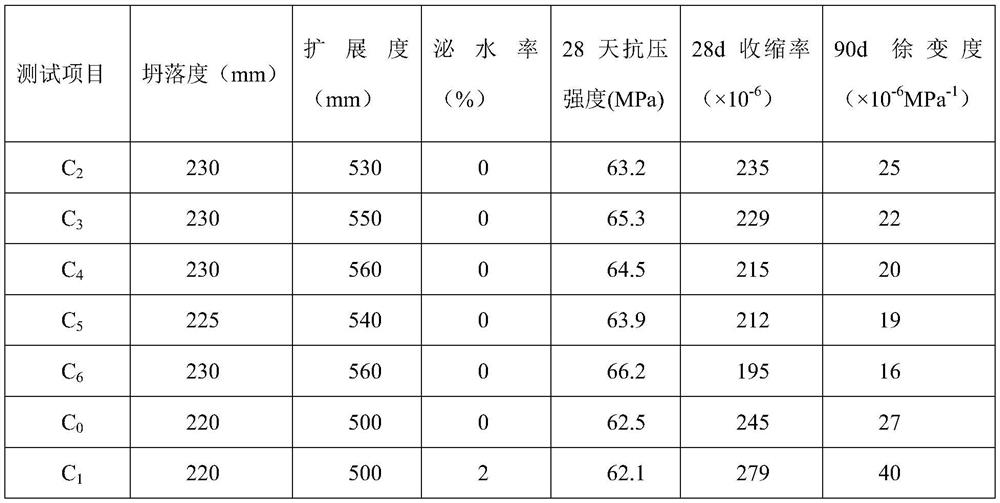

Embodiment 1

[0033] The C60 low-creep concrete suitable for bridge engineering provided by the present embodiment is 2480kg, which specifically includes the following components: 392kg of 52.5 grade early strength Portland cement, 49kg of S105 grade ground blast furnace slag powder, and 49kg of burnt superfine fly ash , 702.043kg of river sand, 1145.425kg of sandstone gravel, 0.049kg of internal curing agent, 0.392g of shrinkable polycarboxylate high-performance water reducer, and 142kg of water.

[0034] Among them, 52.5-grade early-strength Portland cement is compounded with the standard requirements of "General Portland Cement"; The specific surface area of fine-grained blast furnace slag powder is greater than 600m 2 / kg, 28d activity index is greater than 110%; sandstone gravel meets the requirements of the current standard "pebbles and gravel for construction" (GB / T14685) for Class I gravel, the porosity is ≤42%, and the total content of needle-like particles is ≤ 5%, mud content ...

Embodiment 2

[0039] The C60 low-creep concrete suitable for bridge engineering provided by the present embodiment is 2480kg, which specifically includes the following components: 343kg of 52.5-grade early-strength Portland cement, 73.5kg of S105-grade ground blast furnace slag powder, and burnt superfine fly ash 73.5kg, 702.043kg of river sand, 1145.425kg of sandstone gravel, 0.049kg of internal curing agent, 0.392g of shrinkage-reducing polycarboxylate high-performance water reducer, and 142kg of water.

[0040] Among them, 52.5-grade early-strength Portland cement is compounded with the standard requirements of "General Portland Cement"; The specific surface area of fine-grained blast furnace slag powder is greater than 600m 2 / kg, 28d activity index is greater than 110%; sandstone gravel meets the requirements of the current standard "pebbles and gravel for construction" (GB / T14685) for Class I gravel, the porosity is ≤42%, and the total content of needle-like particles is ≤ 5%, mud ...

Embodiment 3

[0045] The C60 low-creep concrete suitable for bridge engineering provided by the present embodiment is 2480kg, which specifically includes the following components: 343kg of 52.5-grade early-strength Portland cement, 73.5kg of S105-grade ground blast furnace slag powder, and burnt superfine fly ash 73.5kg, 701.885kg of river sand, 1145.182kg of sandstone gravel, 0.245kg of internal curing agent, 0.588g of shrinkage-reducing polycarboxylate high-performance water reducer, and 142kg of water.

[0046] Among them, 52.5-grade early-strength Portland cement is compounded with the standard requirements of "General Portland Cement"; The specific surface area of fine-grained blast furnace slag powder is greater than 600m 2 / kg, 28d activity index is greater than 110%; sandstone gravel meets the requirements of the current standard "pebbles and gravel for construction" (GB / T14685) for Class I gravel, the porosity is ≤42%, and the total content of needle-like particles is ≤ 5%, mud ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com