A kind of purification and decolorization method of sulfuric acid ester

A sulfate and decolorization technology, applied in organic chemistry and other directions, can solve the problems of purification and decolorization, deep color, low purity, etc., and achieve the effect of reducing color number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

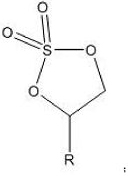

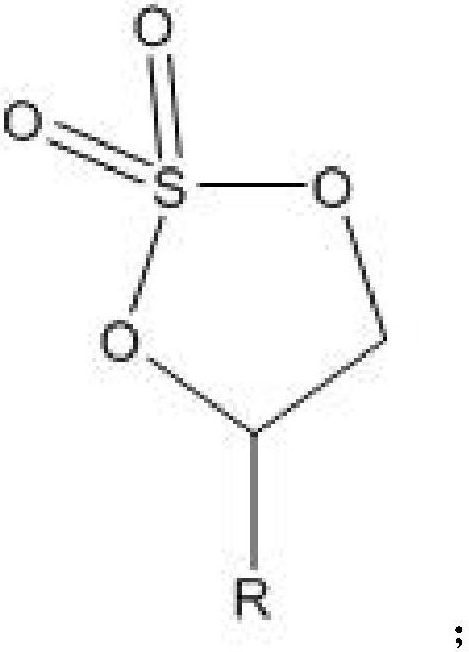

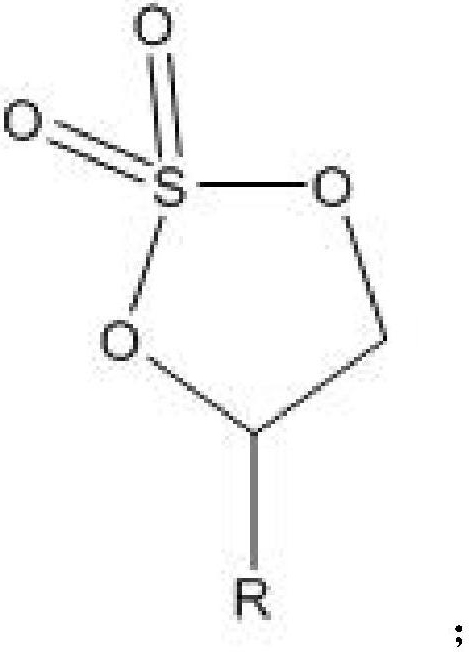

Image

Examples

Embodiment 1

[0028] The purification and decolorization method of sulfuric acid ester described in the present embodiment is as follows:

[0029] Select 500 g of 4-ethyl vinyl sulfate with a purity of 98.9% and a moisture content of 400 ppm, add 1.610 g of hexamethyldisilazane to the 4-ethyl vinyl sulfate for dehydration pretreatment, and react at room temperature for 9 hours. The water content in the 4-ethyl vinyl sulfate after dehydration pretreatment was 20 ppm.

[0030] Add 0.25g BHT to the 4-ethyl vinyl sulfate pretreated by dehydration, and put it into the molecular distillation feed pump storage tank after mixing. , the oil bath was set at 90°C, cooled at 0°C, and after the above parameters were stabilized, the stirring was started, and the stirring speed was 200 rpm, and the light group was collected by feeding the material. The results confirmed that it was the target product 4-ethyl vinyl sulfate, the purity was 99.5%, and the appearance was colorless and transparent.

Embodiment 2

[0032] The purification and decolorization method of sulfuric acid ester described in the present embodiment is as follows:

[0033] Select 500 g of 4-methyl vinyl sulfate with a purity of 98.6% and a moisture content of 200 ppm, add 0.805 g of hexamethyldisilazane to the 4-methyl vinyl sulfate for dehydration pretreatment, and react at room temperature for 3 hours. The water content in the 4-methyl vinyl sulfate after dehydration pretreatment was 30 ppm.

[0034] Add 0.375g BHA to the 4-methyl vinyl sulfate pretreated by dehydration, and put it into the molecular distillation feed pump storage tank after mixing. , the oil bath was set to 80°C, cooled to 0°C, and after the above parameters were stabilized, the stirring was started, and the stirring speed was 150 rpm, and the light group was collected by feeding the material. As a result, it was confirmed that it was the target product, 4-methyl vinyl sulfate, with a purity of 99.5% and a colorless and transparent appearance. ...

Embodiment 3

[0036] The purification and decolorization method of sulfuric acid ester described in the present embodiment is as follows:

[0037] Select 500g of 4-propyl vinyl sulfate with a purity of 98.9% and a moisture content of 400ppm, add 1.789g of hexamethyldisilazane to the 4-propyl vinyl sulfate for dehydration pretreatment, and measure it after 3 hours of reaction at room temperature The water content in the 4-propyl vinyl sulfate after dehydration pretreatment was 30 ppm.

[0038] Add 0.495g BHA to the 4-propyl vinyl sulfate pretreated by dehydration, and put it into the molecular distillation feed pump storage tank after mixing. , the oil bath is set at 80°C, and cooled to -10°C. After the above parameters are stabilized, the stirring is turned on, and the stirring speed is 150 rpm. The light group is collected by feeding the material, and the light group is characterized by GC-MS (gas chromatography-mass spectrometer) and nuclear magnetic resonance. , the results confirmed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com