Polypropylene with high melt index, preparation method thereof and melt-blown fiber cloth

A technology with high melt index and production method, applied in the direction of single-component polypropylene rayon, separation method, fiber treatment, etc., can solve the problems affecting the application field, heavy peroxide odor, narrow molecular weight distribution of polypropylene, etc. Achieve the effects of improving applicability, wide processing window, and improving melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The making and using of embodiments of the invention are discussed in detail below. It should be appreciated, however, that the embodiments provide many applicable inventive concepts that can be embodied in a wide variety of specific contexts. The specific embodiments discussed are illustrative only, and do not limit the scope of the invention.

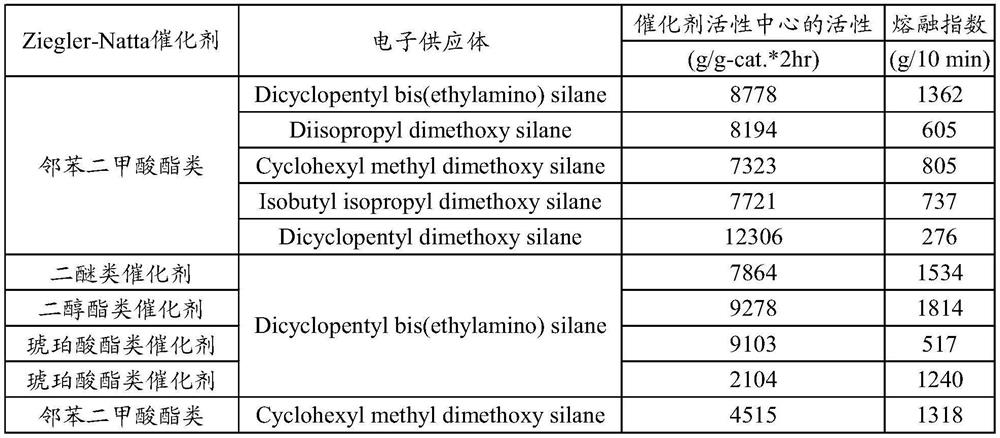

[0020] The polypropylene of the present invention is prepared by the Ziegler-Natta catalyst system, and a specific electron donor is selected to carry out the polymerization process of propylene monomer, so as to solve the defect of the existing Ziegler-Natta catalyst due to hydrogen deactivation, so the present invention The prepared polypropylene has high melt index, high isotactic index, and controllable melting point and molecular weight distribution. Since the obtained polypropylene has a higher melt index, it can be used to produce polypropylene fibers with smaller silk diameters by using the melt-blown process, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com