Method for calculating heat capacity of block material based on sound velocity and computer readable storage medium

A technology of bulk materials and sound velocity, applied in computer-aided design, calculation, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

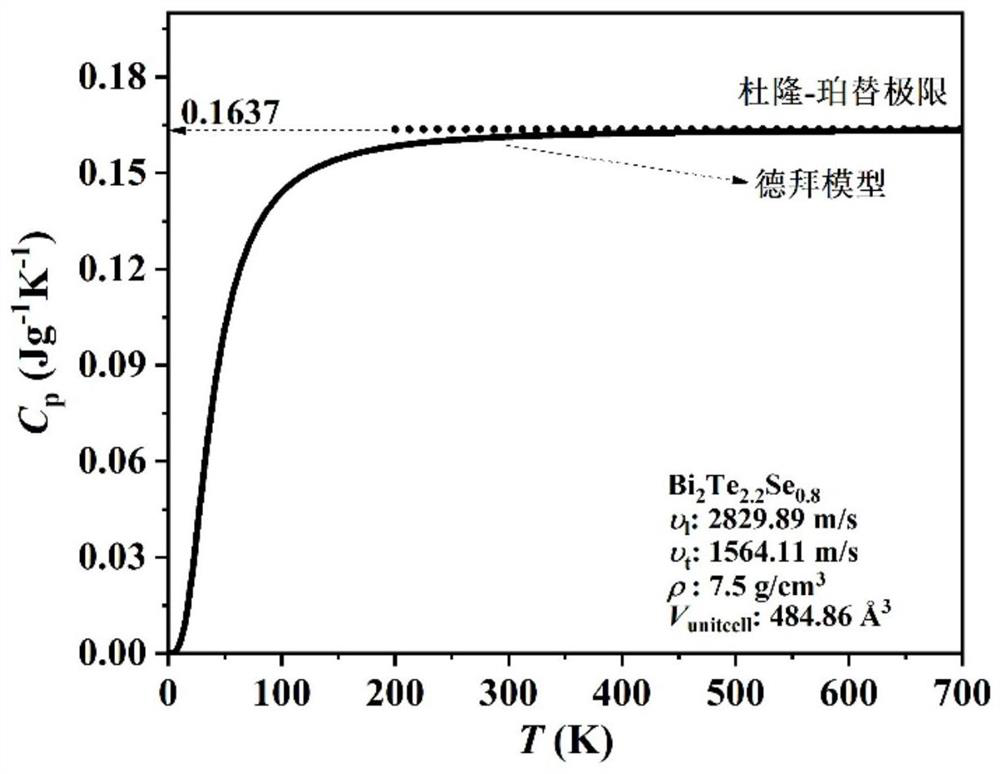

[0140] This embodiment tests and calculates Bi 2 Te2.2 Se 0.8 Sample C p , the test steps are as follows:

[0141] (1) will Bi 2 Te 2.2 Se 0.8 The sample is processed into a disc with a diameter of about 10 mm and a thickness of about 1 mm. The thickness of the wafer is 2.145mm, marked as d, and the thickness error of different positions of the wafer should be less than ±0.005mm.

[0142] (2) Place the processed wafer on the longitudinal wave / shear wave probe. In order to form a good contact between the probe and the sample, a thin layer of longitudinal wave / shear wave coupling agent should be applied between the probe and the sample;

[0143] (3) Turn on the ultrasonic generator and debug the oscilloscope. Periodic oscillation signals can be observed in the oscilloscope. Select n cycles, mark the start time of n cycles as t1 and end time as t2, then the time of a single cycle t=(t2-t1) / 2.

[0144] (4) Calculate the longitudinal sound velocity v of the above-mentioned ...

Embodiment 2

[0151] This embodiment tests and calculates Bi 0.4 Sb 1.6 Te 3 Sample C p , the test procedure is the same as in Example 1, and the thickness of the sample is 1.017mm. Figure 6 for the same Bi 0.4 Sb 1.6 Te 3 5 repeated test results of the sample shear wave sound velocity and longitudinal wave sound velocity, it can be seen from the figure that the relative standard deviation of the multiple measurement results is about 0.5%. Adopt the method described in this embodiment to measure Bi 0.4 Sb 1.6 Te 3 Sample C p The result is as Figure 7 Its relative standard deviation is shown in Table 2. When temperature is 1-20K, embodiment 2 records Bi 0.4 Sb 1.6 Te 3 C p The relative standard deviation is 1-2%. Further increasing the temperature, the relative standard deviation decreases rapidly, above room temperature, the relative standard deviation is less than 1%.

[0152] Table 2

[0153]

Embodiment 3

[0155] This embodiment tests and calculates Mg 3.2 Sb 1.5 Bi 0.49 Te 0.01 Sample C p , the test procedure is the same as in Example 1, and the thickness of the sample is 1.019mm. Figure 8 for the same Mg 3.2 Sb 1.5 Bi 0.49 Te 0.01 5 repeated test results of the sample shear wave sound velocity and longitudinal wave sound velocity, it can be seen from the figure that the relative standard deviation of the multiple measurement results is less than 1%. Adopt the method described in this embodiment to measure Mg 3.2 Sb 1.5 Bi 0.49 Te 0.01 Sample C p The result is as Figure 9 Its relative standard deviation is shown in Table 3. When temperature is 1-20K, embodiment 3 records Mg 3.2 Sb 1.5 Bi 0.49 Te 0.01 C p The relative standard deviation is 1-2%. Further increasing the temperature, the relative standard deviation decreases rapidly, above room temperature, the relative standard deviation is less than 1%.

[0156] table 3

[0157]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com