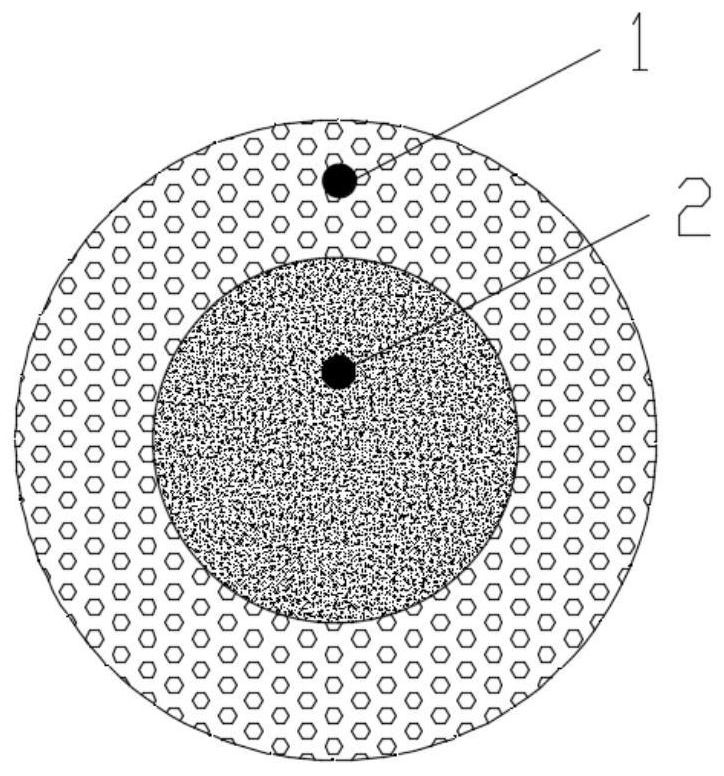

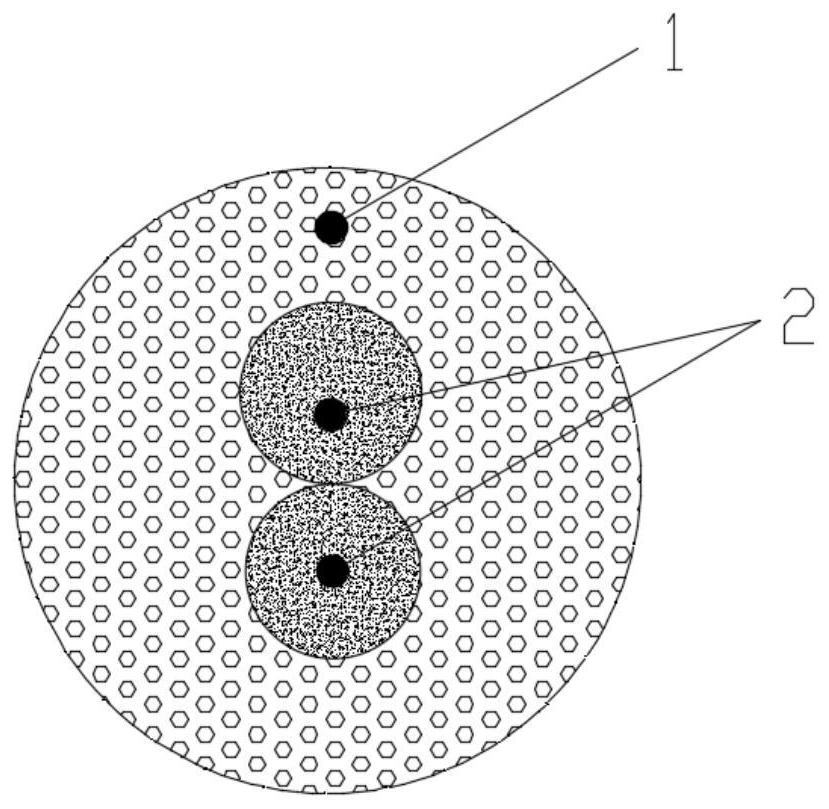

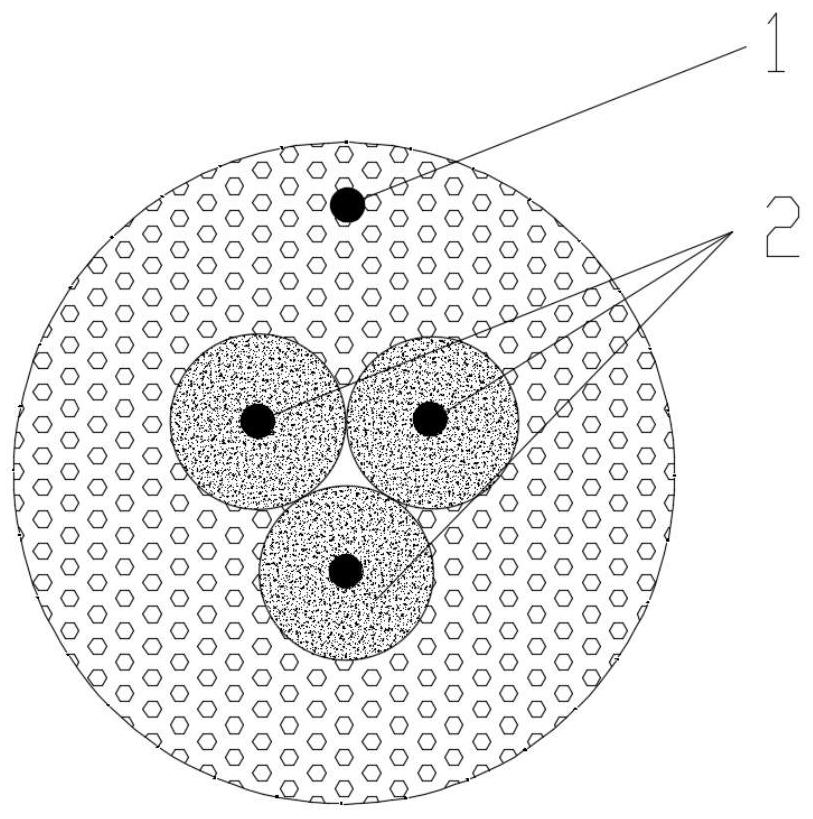

Alumina ball with construction waste core aggregate wrapped by activated alumina and preparation method of alumina ball

A technology of activated alumina and construction waste, which is applied in the directions of alkali metal oxides/hydroxides, chemical instruments and methods, physical/chemical process catalysts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Use bauxite as raw material to prepare active alumina wrapped construction waste core aggregate to prepare sewage purification materials, ordinary alumina powder made from bauxite ore, and then compress and compound with crushed and screened construction waste core aggregate, The novel composite high-efficiency activated alumina ball formed after activation is characterized in that the steps of the preparation method are as follows:

[0035] (1) The bauxite ore is screened and crushed to form a powder, and the powder is mixed with a high-temperature aluminum hydroxide solution at a temperature of 110-130°C to form a sodium aluminate solution, and the residue is removed by filtration.

[0036] (2) Sodium aluminate is heated and cooled to crystallize and precipitate to form aluminum hydroxide crystals. After precipitation and washing, a sodium hydroxide filter cake is formed. The filter cake is calcined and dried at a temperature of 950-1200°C to form alumina.

[0037] (3...

Embodiment 2

[0045] The general activated alumina powder is used to prepare activated alumina and wrap the core aggregate of construction waste to prepare sewage purification materials. The seed crystals are prepared from pseudo-boehmite, and then hydrated with general activated alumina powder to obtain activated alumina. The alumina powder and the crushed and screened construction waste core aggregate are repeatedly compressed and compounded to form a new type of composite high-efficiency activated alumina ball after activation. It is characterized in that the steps of the preparation method are as follows:

[0046] (1) Grind pseudo-boehmite and put it in a seed crystal preparation tank, add pure water with a water temperature of 45-55°C to make a slurry, add 100g / L of appropriate amount of aluminum nitrate and aluminum hydroxide, and adjust the pH value to 6 ~9, injecting steam for hydration reaction to obtain seed crystals.

[0047] (2) Dry and pulverize industrial-grade aluminum hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com