Direct-writing nozzle based on plasma surface modification, direct-writing system device comprising direct-writing nozzle and direct-writing method

A plasma and surface modification technology, applied in the field of 3D printing, can solve the problems of large time and effort, time-consuming and labor-intensive, and time-consuming, and achieve the effect of reducing participation, waste, and time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] Example 1

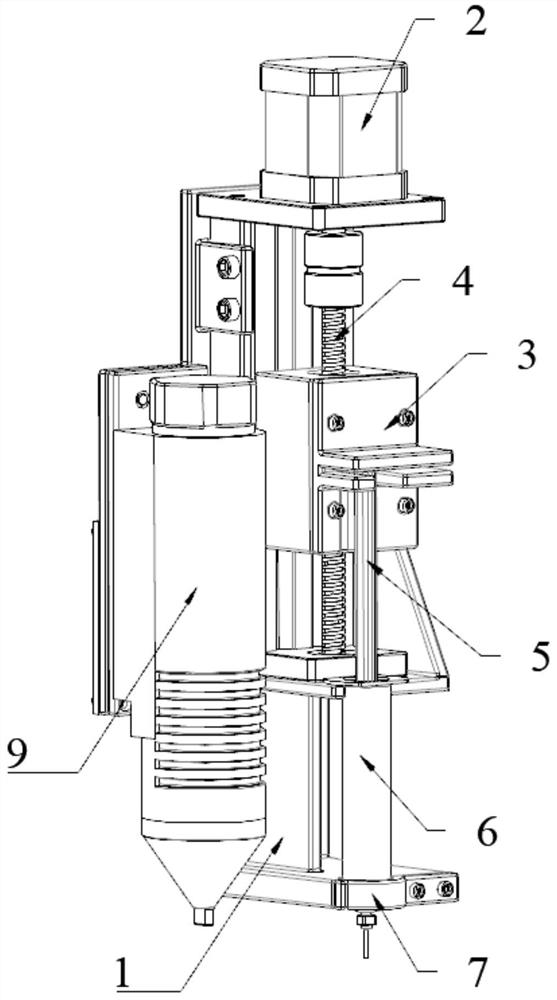

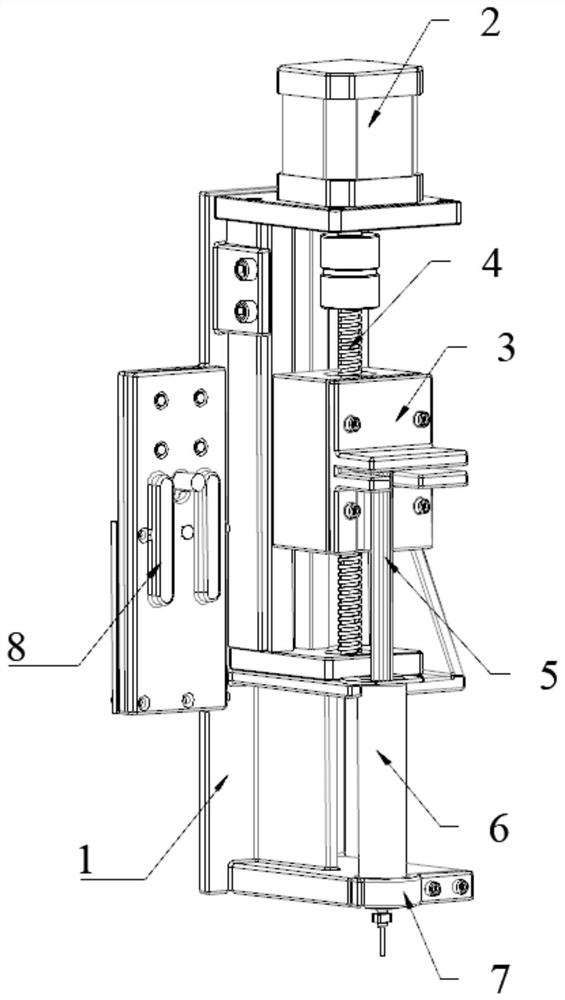

[0053] This embodiment provides a direct write method using a direct write system device provided by a specific embodiment, and a hydrogel is used as the ink, and the direct write method specifically includes the steps of:

[0054] (1) The substrate is placed on the workstock, and the plasma nozzle 9 performs hydrophilization of the substrate along a predetermined pattern trajectory, the moving speed of the plasma nozzle 9 in the hydrophilization process is 400 mm / min, plasma The vertical distance between the discharge port of the body spray head 9 and the substrate is 10 mm, the plasma power is 200 W, the plasma pressure is 0.1 MPa;

[0055] (2) After the hydrophilization treatment is completed, the ink injection is injected into the surface of the substrate, and the hydrogel forms a 10 mm wide line on the surface of the substrate, and the preset pattern is formed by the line.

Example Embodiment

[0056] Example 2

[0057] This embodiment provides a direct write method, a direct write system device provided by a specific embodiment, a 3D direct writing of an ionic liquid gel as an ink, and the direct writing method includes the following steps:

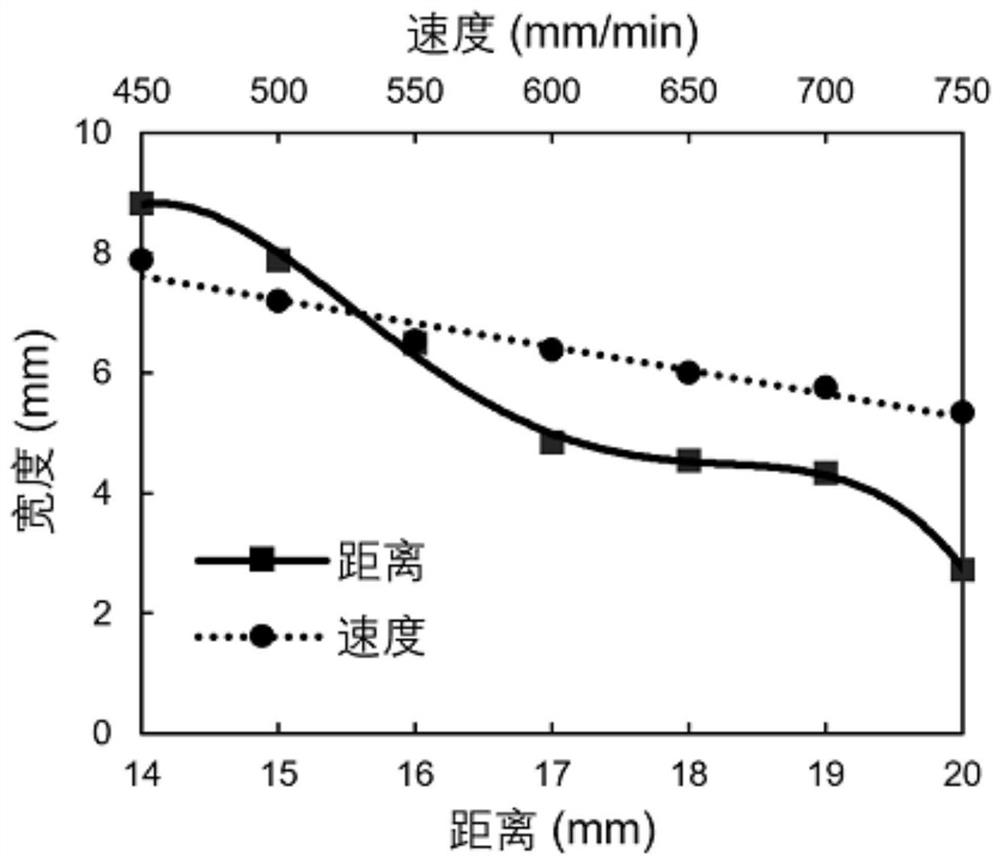

[0058] (1) The substrate is placed on the working table, and the plasma nozzle 9 performs hydrophilicization of the substrate along a predetermined pattern trajectory, the moving speed of the plasma nozzle 9 in the hydrophilized treatment is 450 mm / min, plasma The vertical distance between the discharge port of the body spray head 9 and the substrate is 12 mm, the plasma power is 180W, the plasma pressure is 0.08 MPa;

[0059] (2) After the hydrophilization treatment is completed, the ink injection is injected into the surface of the substrate, and the ionic liquid gel forms an 8 mm wide line on the surface of the substrate, and the preset pattern is formed by the line.

Example Embodiment

[0060] Example 3

[0061] This embodiment provides a direct write method using a direct write system device provided by a specific embodiment, and a hydrogel is used as the ink, and the direct write method specifically includes the steps of:

[0062] (1) The substrate is placed on the workstock, and the plasma nozzle 9 performs hydrophilicization of the substrate along a predetermined pattern trajectory, the moving speed of the plasma nozzle 9 in the hydrophilization process is 550 mm / min, plasma The vertical distance between the discharge port of the body spray head 9 and the substrate is 14 mm, the plasma power is 170W, the plasma pressure is 0.06 MPa;

[0063] (2) After the hydrophilization treatment is completed, the ink syringe is injectable hydrogel to the surface of the substrate, and the hydrogel forms a 6 mm wide line on the surface of the substrate, and the preset pattern is formed by the line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap