Composite bent sheet forming method and mold

A composite material and thin plate forming technology, which is applied in the field of composite material processing, can solve the problem that the forming method cannot take into account processing quality and cost, and achieve low cost, simple production and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be described in conjunction with the drawings in the embodiments of the present invention.

[0036] Such as Figure 1 to 6 As shown, the present invention provides a composite curved thin plate forming method, including the following steps.

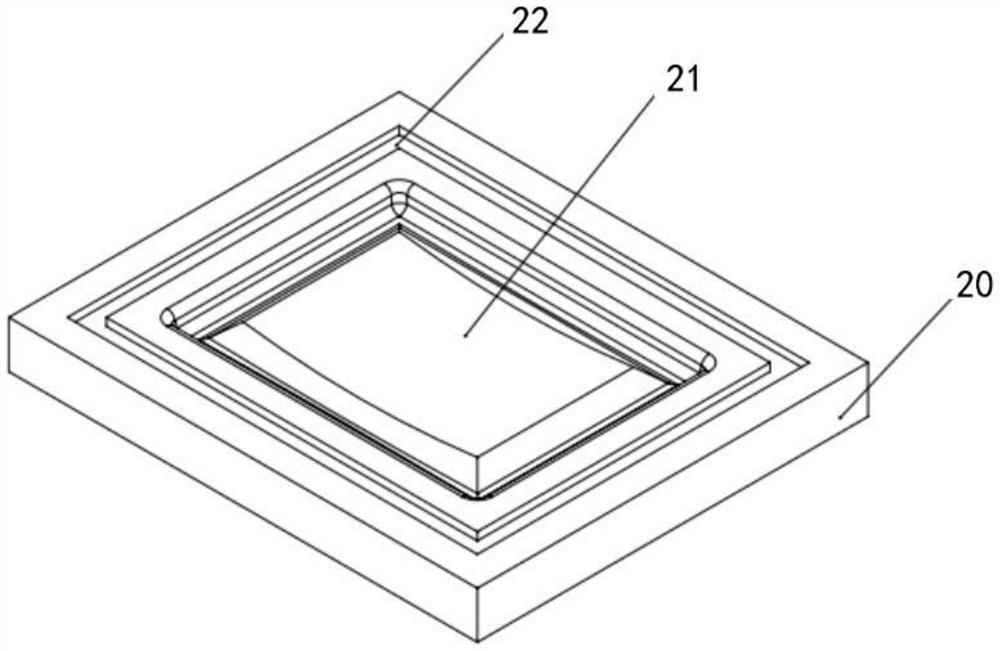

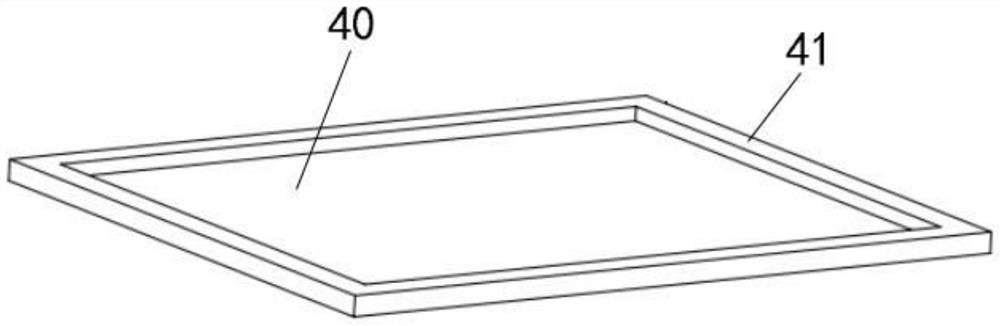

[0037] Step S1, according to the shape of the composite material, a composite curved sheet molding die is fabricated, and the composite curved sheet molding die includes a base 20 and a cover 30; the base 20 is provided with the inner cavity 21 and the sealing groove 22, the shape of the inner cavity 21. Matching the shape of the composite material requires a shape, the sealing groove 22 is arranged on a circle side around the inner cavity 21; the upper cover 30 is provided with a pneumper interface 31, and the air nozzle interface 31 conducts two surfaces opposite to the cover 30;

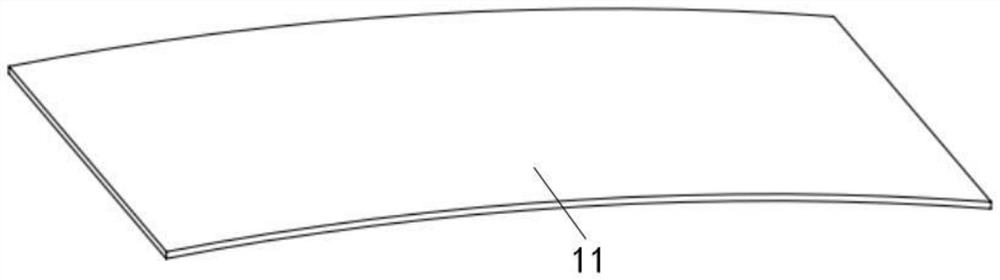

[0038] Step S2, according to the shape of the composite material, the silica gel g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com