White tea production process

A production process, technology of white tea, applied in tea treatment before extraction, local agitation dryer, static material dryer, etc., can solve the problems of poor drying effect of tea leaves, etc., and achieve the effect of convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application will be described in further detail below in conjunction with the accompanying drawings.

[0042] The embodiment of the present application discloses a white tea production process. The white tea production process comprises the following steps: Step 1: picking;

[0043] Step 2: Spread the picked white tea on a drying rack and place it outdoors for drying;

[0044] Step 3: Impurity removal, sending the dried white tea into an electrostatic cleaner for impurity removal;

[0045] Step 4: Screening, the white tea after removal of impurities is sent to the winnowing machine for screening;

[0046] Step 5: Drying, putting the screened white tea into a drying box for drying;

[0047] Step 6: Packing, put the dried white tea in step 5 into a packing box, and pack it through a shrink wrapping machine.

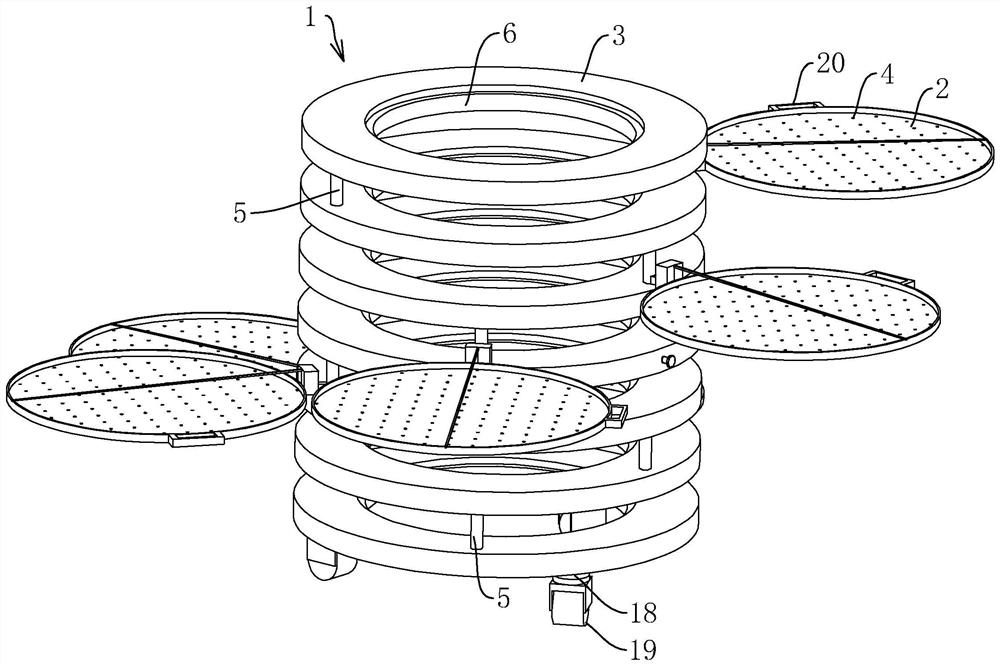

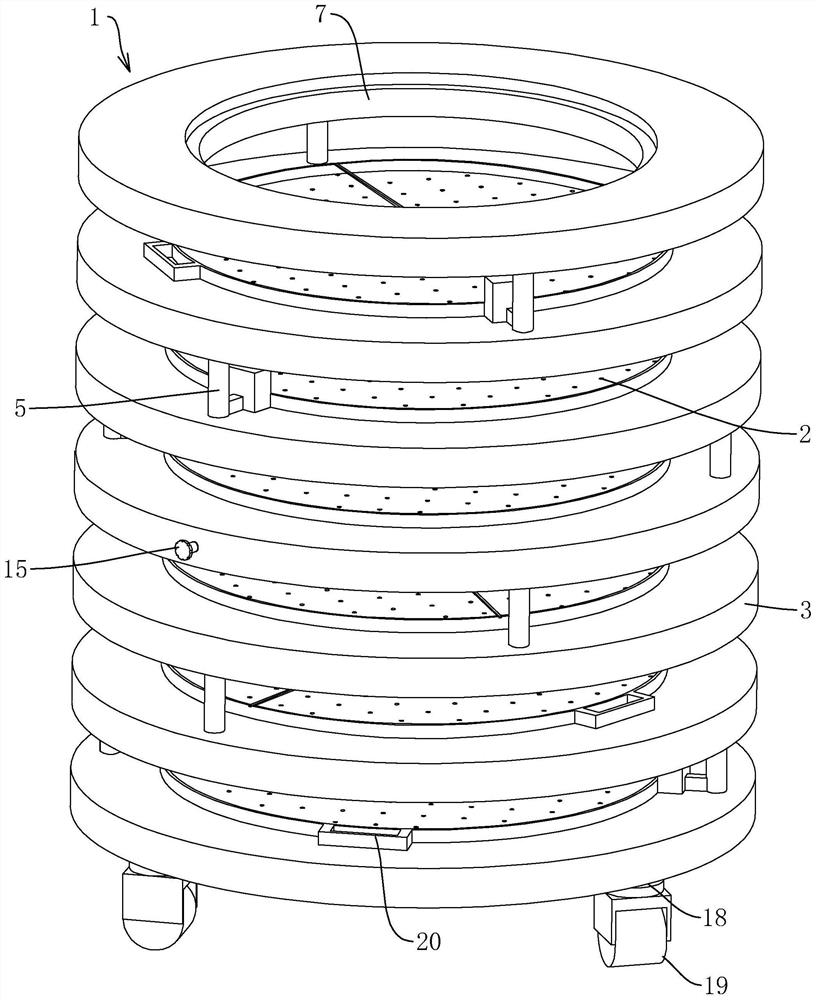

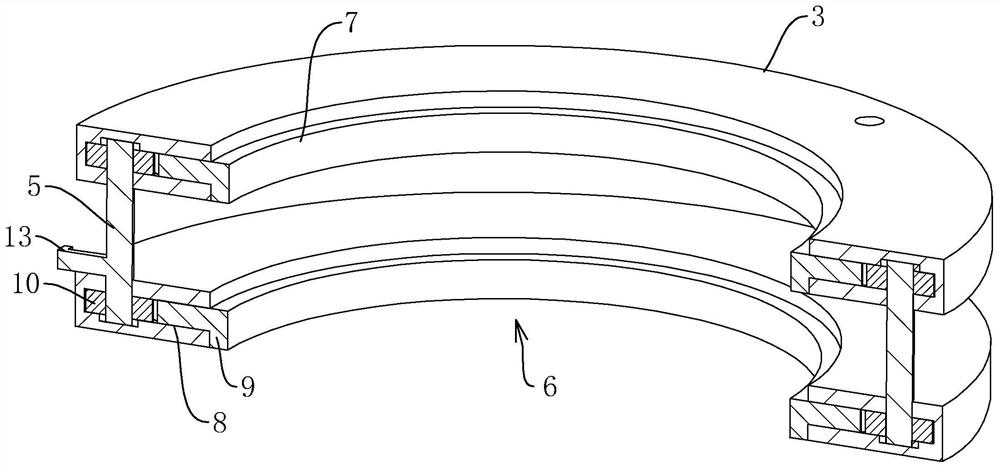

[0048] refer to figure 1 , 2 , the drying rack in step 2 includes a rack body 1 and a drying tray 2 arranged on the rack body 1 , the drying tray 2 has a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com