A kind of surface layer decarburization phase gradient cemented carbide material and preparation method thereof

A hard alloy and decarburization technology, applied in the field of hard alloy wear-resistant materials, can solve the problems of long cycle time and complicated preparation process, and achieve the effect of easy process control, simple preparation process and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A second aspect of the present invention provides a method for preparing a surface decarburized cemented carbide material, preferably a method for preparing the surface decarburized cemented carbide material described in the first aspect of the present invention, the method comprising the following steps:

[0043] Step 1. Mix binder, (W,Ti)C powder, WC powder, W powder, carbonitride or nitride.

[0044] According to the present invention, in step 1, the binder, (W,Ti)C powder, WC powder, W powder, carbonitride or nitride are as described in the first aspect of the present invention.

[0045] Step 2, grinding and drying the mixture obtained in step 1, and pressing it into a green body.

[0046] According to the present invention, in step 2, the mixture obtained in step 1 is ground, preferably by using common grinding equipment in the field, such as a ball mill.

[0047] According to the present invention, in step 2, a ball mill is used for grinding, and the grinding bal...

Embodiment 1

[0100] Take the raw material by weight percentage to prepare the surface layer decarburization phase gradient cemented carbide, wherein the Co powder with an average particle size of 1.1 μm accounts for 10%, and the Ti(C) powder with a particle size of 3.0 μm 0.5 ,N 0.5 ) powder accounted for 3.9%, particle size of 2.3μm (Ti 0.42 ,W 0.58 ) C powder accounts for 17.3%, WC powder with a particle size of 6.4 μm accounts for 58%, and the remaining W powder with a particle size of 1.1 μm, the sum of the proportions of each component is 100%;

[0101] Co powder, Ti(C 0.5 ,N 0.5 ) powder, (Ti 0.42 ,W 0.58 ) C powder, WC powder, and W powder are added to the drum ball mill for grinding. The grinding ball is Φ6mm WC-8wt% Co cemented carbide ball, the weight ratio of ball to material is 10:1, and the grinding medium is absolute ethanol , the amount of absolute ethanol added is 300mL, and ground for 25 hours at a grinding speed of 60r / min;

[0102] After grinding, filter through a...

Embodiment 2

[0114] Repeat the preparation process of Example 1, the only difference is that the proportion of Co powder is 11.5%, the proportion of WC powder is 56%, and the other processes are the same as in Example 1.

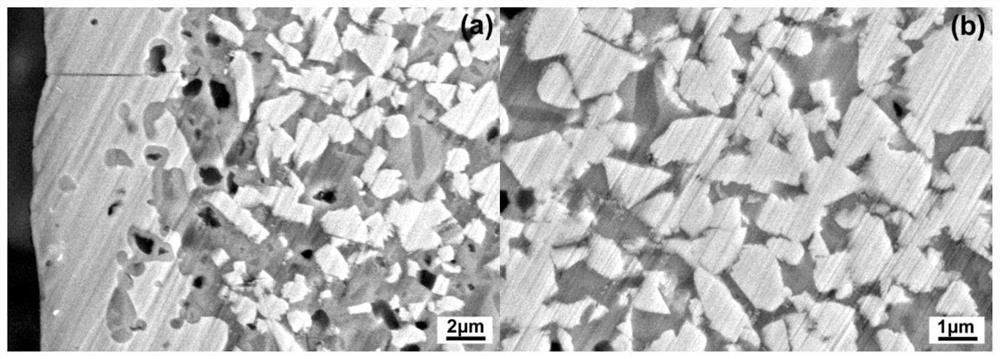

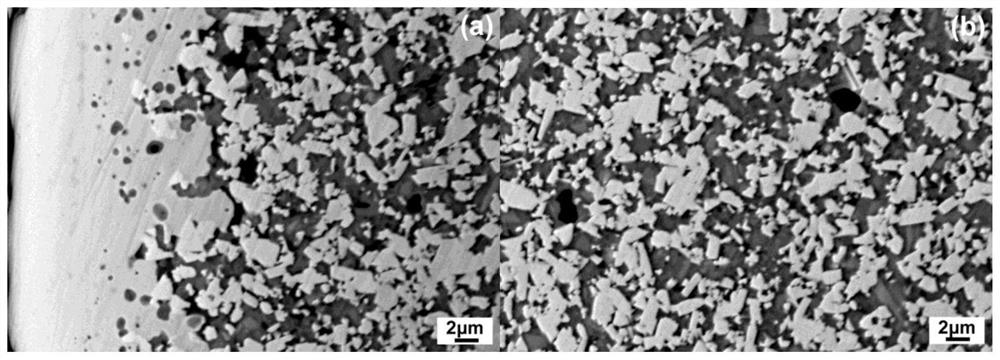

[0115] The near-surface region and internal microstructure of the prepared decarburized cemented carbide materials were measured as follows: figure 2 (a) and figure 2 (b) shown. From figure 2 It can be seen from (a) that the near-surface region of the prepared cemented carbide is a decarburized phase structure, from figure 2 It can be seen in (b) that the interior is a normal phase structure, indicating that the surface decarburization phase gradient cemented carbide material has been successfully prepared. And there is a smooth transition from the surface layer to the internal composition without sudden changes, and there is no stress concentration on the interface between the surface layer and the interior.

[0116] The surface thickness of the decarburized pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com