Micro exhaust valve

A technology of micro-exhaust and vent holes, which is applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of small exhaust volume and cannot be enlarged, and achieve the effect of increasing exhaust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

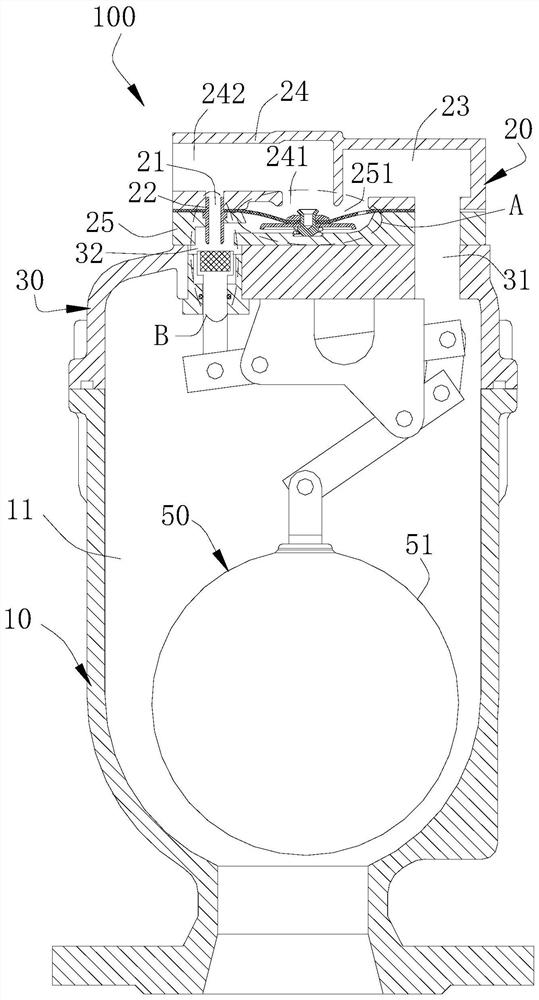

[0064] Example one

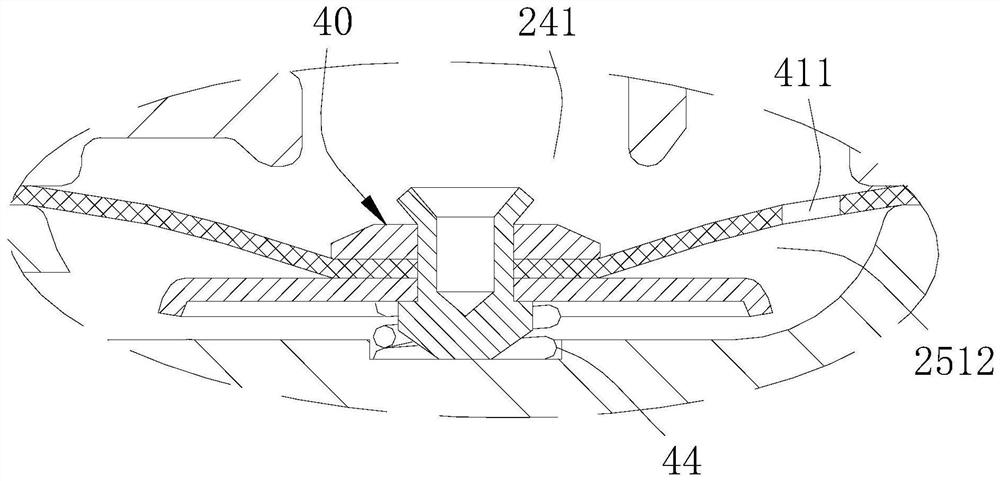

[0065] See figure 2 The spool assembly 40 includes a diaphragm 41, and the diaphragm 41 is provided between the first valve head 24 and the second valve head 25, and the diaphragm 41 is capable of blocking the main valve port 241, the diaphragm 41 cooperates with the second chamber 251. The communication chamber 2512 is formed, and the converging chamber 2512 is disposed away from the first passage 23 and the main valve port 241, and the communication chamber 2512 communicates with the first chamber 32, the damping hole 411 is opened on the diaphragm 41, and the first passage 23 passes the damping hole 411 and The connecting chamber 2512 is in communication, and the diaphragm 41 is located on the side of the side surface of the connecting cavity 2512 larger than the cross-sectional area of the main valve port 241, so that in the case where the pressure balance between the diaphragm 41, the diaphragm 41 can be elastically becoming The direction of the main va...

Example Embodiment

[0072] Example 2

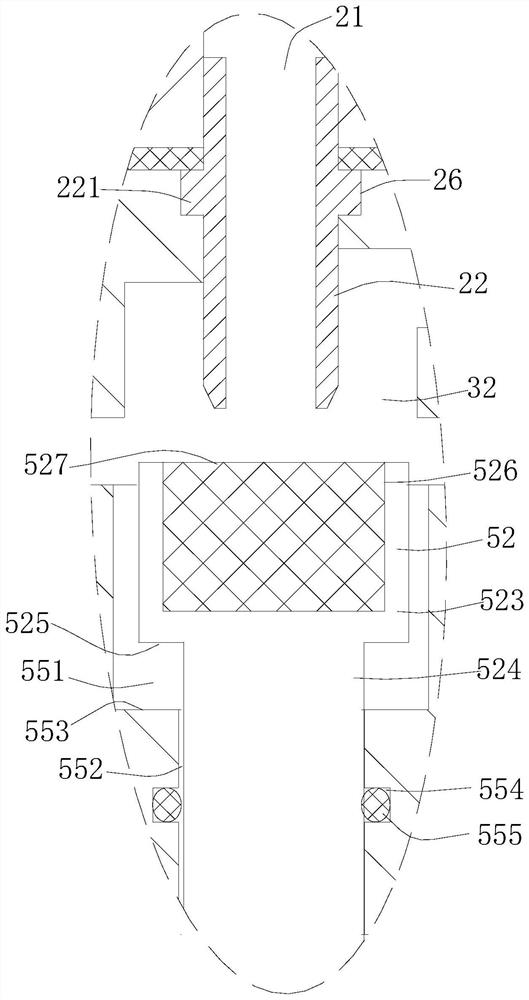

[0073] See Figure 5 The present embodiment is substantially the same as the structure of the embodiment, and the same is not described in the same, and the difference is:

[0074] The spool assembly 40 includes a piston portion 45 and an elastic member 44, and the piston portion 45 is provided in the valve head assembly 20 and forms a connecting chamber 2512 with the valve head assembly 20, and one end of the elastic member 44 abuts the inner wall of the connecting cavity 2512. One end abuts against the piston portion 45, and the communication chamber 2512 can communicate or partition with the vent hole 21, and the piston portion 45 can move along the axial direction 2512 in the valve head assembly 20 to open or close the main valve port 241, the main The cross-sectional area of the valve port 241 is smaller than the area of the piston portion 45 toward the surface of the connecting chamber 2512. It is to be explained that the piston portion 45 here refers t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap