A Method for On-line Shape Quality Judgment of Hot-rolled Strip Steel

A hot-rolled strip and shape technology, applied in the direction of comprehensive factory control and profile control, can solve the problems of stuck quality judgment, misjudgment of strip shape, incomplete data consideration, etc., to optimize judgment rules and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

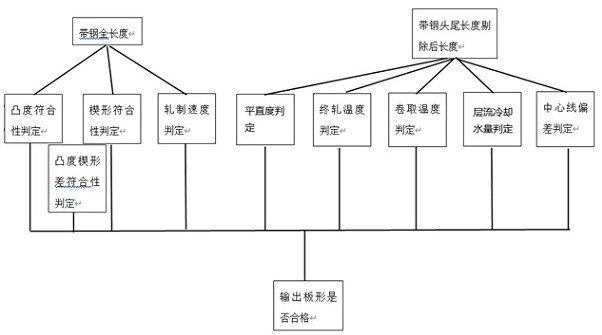

Method used

Image

Examples

Embodiment 1

[0030] Example 1: TCX510L beam steel 1250*4.0mm specification hot-rolled plate shape determination is as follows.

[0031]The curve collection of 8 key process control parameters of TCX510L beam steel, including crown, wedge, flatness, finish rolling temperature, coiling temperature, laminar cooling water volume, rolling speed, strip centerline deviation parameters. Based on the preset determination rules in the hot-rolled strip online shape quality determination system, the eight key process control parameter curves of shape are determined one by one.

[0032] 1) Judgment of crown, the said judgment rule is, the average crown of the strip is 55 microns ≤ the standard average upper limit of 70 microns, the maximum crown of the strip is 60 microns ≤ the standard upper limit of 80 microns, and the The minimum strip crown is 35 microns ≥ the standard lower limit of 20 microns; the above three judgments all meet the requirements, and the output crown control meets the plate shape ...

Embodiment 2

[0041] Example 2: SAE1008 cold-rolled stock 1270*1.8mm specification hot-rolled shape determination is as follows.

[0042] Collection of 8 key process control parameters of SAE1008 cold-rolled stock 1270*1.8mm specification, including crown, wedge, flatness, finish rolling temperature, coiling temperature, laminar cooling water volume, rolling speed, strip steel Centerline deviation parameter. Based on the preset determination rules in the hot-rolled strip online shape quality determination system, the eight key process control parameter curves of shape are determined one by one.

[0043] 1) Judgment of crown, the said judgment rule is that the average crown of the strip is 37 microns ≤ the standard average upper limit of 60 microns, the maximum crown of the strip is 52 microns ≤ the standard upper limit of 70 microns, and the The minimum value of strip crown is 25 microns ≥ the standard lower limit of 20 microns; the above three judgments all meet the requirements, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com