Method for filtering air on inlet side of centrifugal air compressor in smelting industry

A centrifugal air compressor and air filtration technology, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., can solve the problem of cooler tube wall thinning and tube wall thickness. 1. Problems such as capital occupation, to achieve the effect of reducing operating costs and operating risks, improving inlet air quality, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

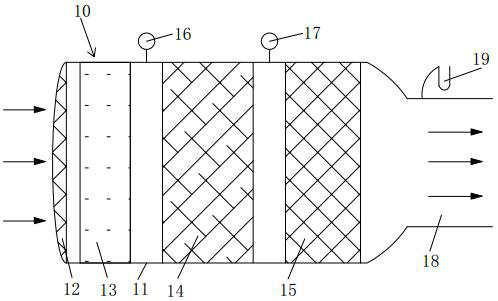

[0023] refer to figure 1

[0024] A method for filtering air on the inlet side of a centrifugal air compressor in the smelting industry, comprising the following steps:

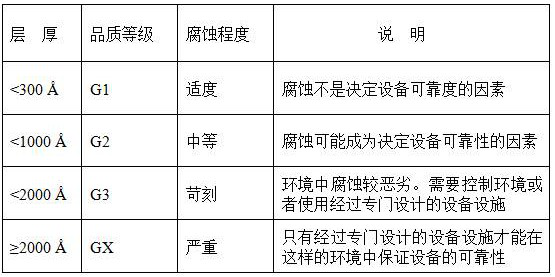

[0025] (1) Confirm the air quality level in the equipment operating environment: Hang the test piece at the inlet filter of the air compressor. The test piece is composed of two groups, namely copper and silver; the suspension period of the test piece is more than 30 days. Let copper and silver flakes chemically react with corrosive gases in the air:

[0026] A. Infer the main corrosive gases in the air according to the chemical reaction;

[0027] B. Since the reactants will accumulate on the surface during the reaction and increase the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com