Method for recovering light hydrocarbon in refinery dry gas

A refinery dry gas and recovery method technology, applied in chemical instruments and methods, hydrocarbon purification/separation, absorption purification/separation, etc., can solve problems such as low recovery rate, high energy consumption, and dry gas "not dry" , to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

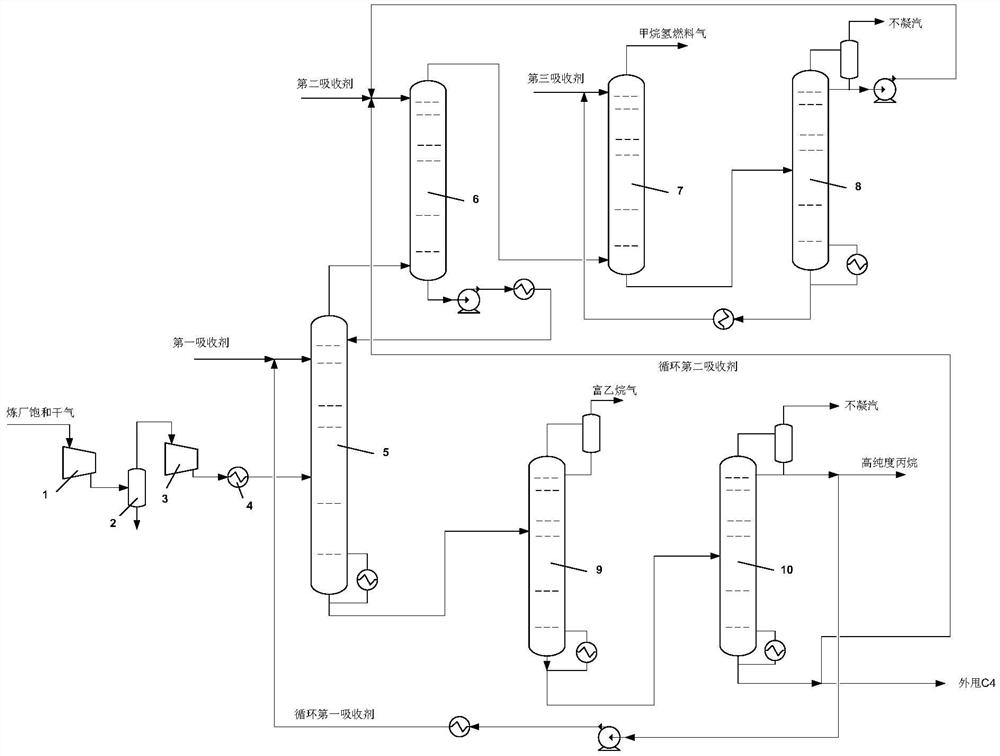

[0035] see figure 1 A method for recovering light hydrocarbons in refinery dry gas, comprising the steps of:

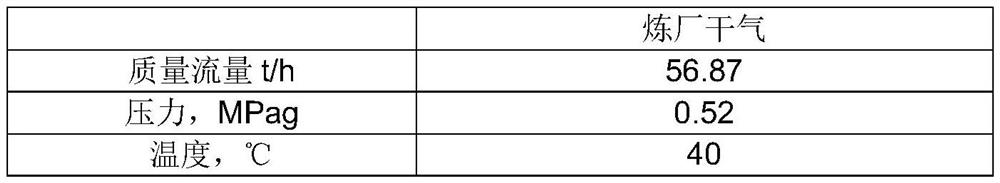

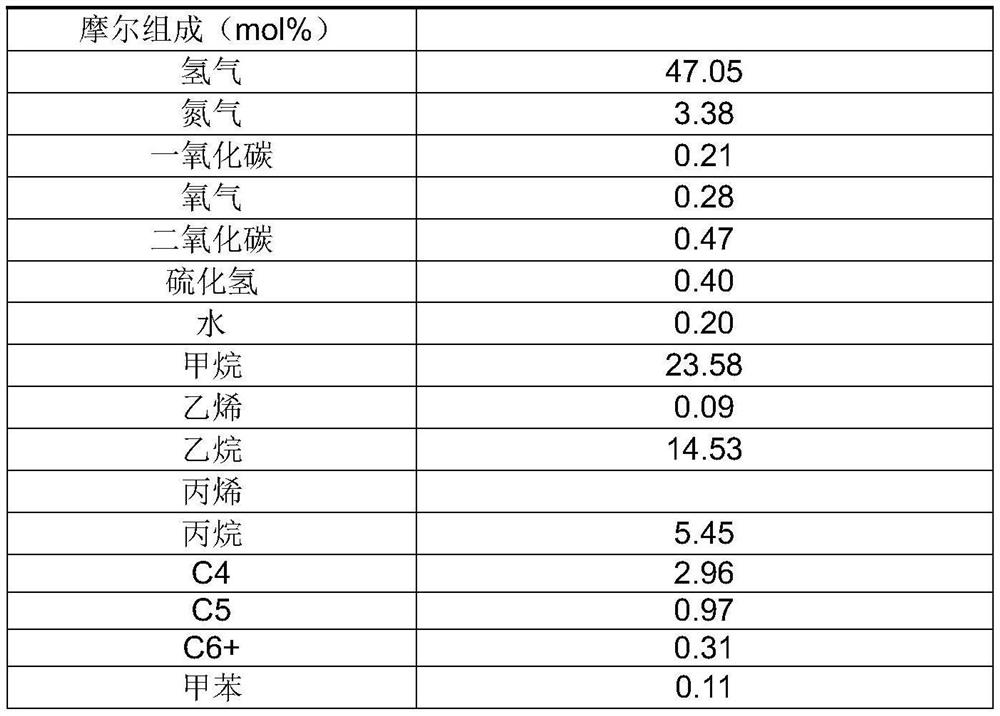

[0036] S1. The saturated dry gas of the refinery is compressed by the first gas compressor 1 and enters the impurity removal equipment 2 for desulfurization and decarbonization (according to the nature and requirements of raw materials, there may be no impurity removal equipment or only for purified methane hydrodesulfurization and decarbonization) , and then carry out 2-4 sections of the second gas compressor 3 to continue pressurizing to 3-4.5MPag, cooled by the gas cooler 4 to 10°C-40°C and enter the first absorption tower 5;

[0037] S2, the first absorption tower 5 adopts liquid phase propane or the C3 fraction rich in propane as the first absorbent, and the first absorbent enters the first absorption tower 5 from the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com