Polyphenylene sulfide/nylon 6 composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, applied in the field of polymer materials, can solve problems such as poor compatibility, large addition amount, and insufficient compatibility improvement effect, and achieve good impact performance, price reduction, and interface bonding. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

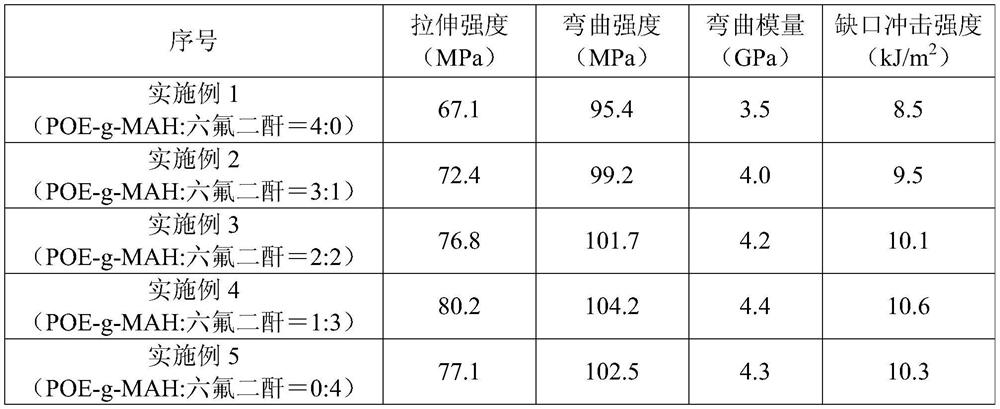

Embodiment 1

[0029] (1) Polyphenylene sulfide (Toray, Japan, average weight average molecular weight 50,000), nylon 6 (Shanghai BASF), compatibilizer (maleic anhydride grafted ethylene-octene copolymer POE-g-MAH, USA Dow), hexafluorodianhydride (Shanghai Merrill Chemical Company), antioxidant (1010, Jiangsu Aikang Biology), lubricant (ethylene bisstearic acid amide, Qingdao Jisi Polymer Company) after drying, in Stir evenly in a high-speed mixer, melt and extrude the mixture through a twin-screw extruder, cool it in a water tank and cut it into pellets through a pelletizer. After drying, the polyphenylene sulfide / nylon 6 composite material is obtained.

[0030] The mass ratio of polyphenylene sulfide, nylon 6, compatibilizer, hexafluorodianhydride, antioxidant and lubricant is 100:30:4:0:0.1:0.1. The interval temperatures of the twin-screw extruder were 290, 310, 310, 310, 310, and 300° C., and the screw speed was 50 rpm.

[0031] (2) The above-mentioned pellets were dried, and prepared ...

Embodiment 2

[0033] According to the preparation process of Example 1, wherein the mass ratio of polyphenylene sulfide, nylon 6, compatibilizer, hexafluorodianhydride, antioxidant, and lubricant is 100:30:3:1:0.1:0.1, poly Phenylsulfide / Nylon 6 Standard Spline. (that is, the total mass content percentage of compatibilizer and hexafluorodianhydride remains unchanged, and the ratio of the two is changed, the same below)

Embodiment 3

[0035] According to the preparation process of Example 1, wherein the mass ratio of polyphenylene sulfide, nylon 6, compatibilizer, hexafluorodianhydride, antioxidant, and lubricant is 100:30:2:2:0.1:0.1, poly Phenylsulfide / Nylon 6 Standard Spline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com