Variable stiffness support device and method for floating slab track

A supporting device and variable stiffness technology, applied in the field of rail transit, can solve problems such as unadjustable stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

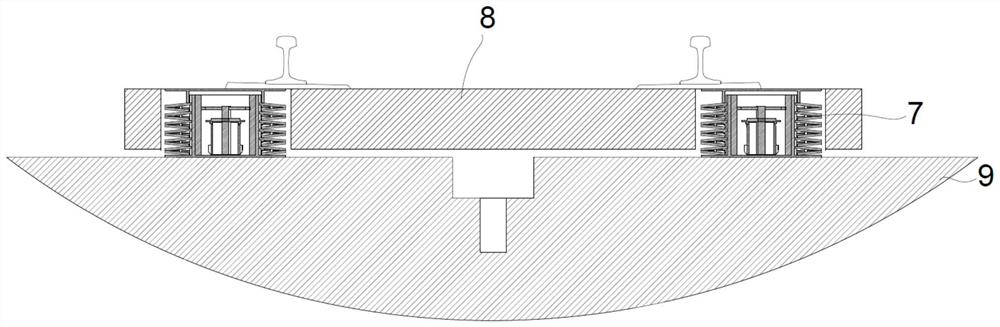

[0042] Such as figure 1 As shown, the variable stiffness support device 7 for the floating plate track of this embodiment is installed in the reserved hole of the support device of the floating plate 8 .

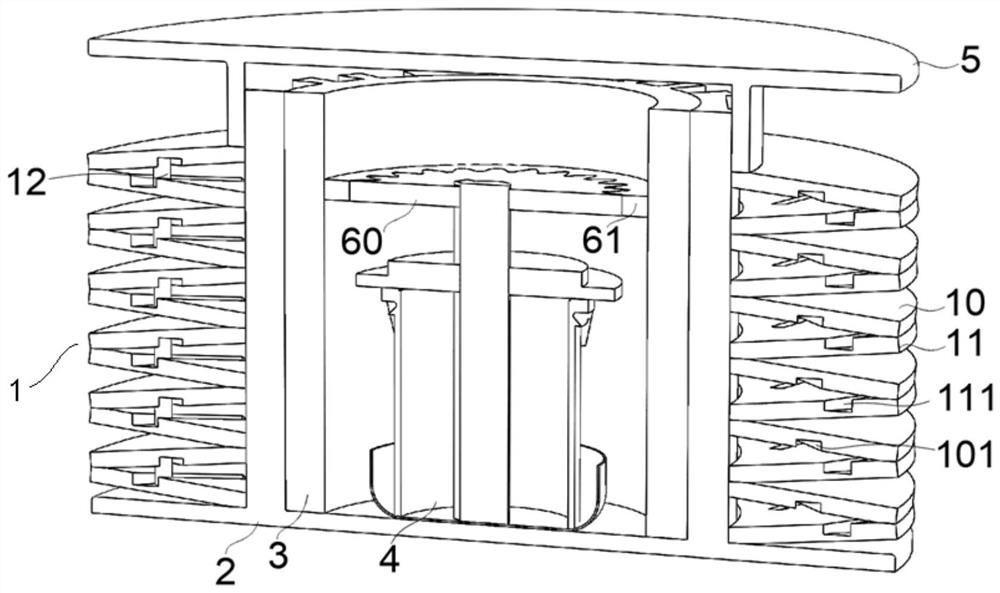

[0043] Such as figure 2 , 3 , 4, the variable stiffness support device for the floating plate track in this embodiment includes 6 annular basic support units 1, base 2, inner sleeve 3, DC motor 4, top cover 5 and transmission structure 6.

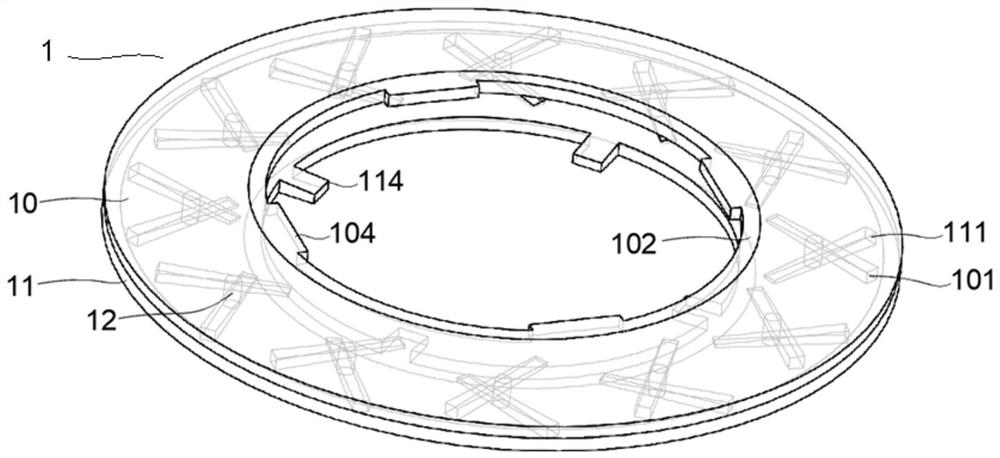

[0044] Each annular basic support unit 1 is composed of an annular fixed upper disc spring 10 , an annular movable lower disc spring 11 and 12 stiffness adjustment blocks 12 . The annular fixed upper disc spring 10 includes an upper disc spring notch 101 , an upper disc spring inner diameter support surface 102 , an upper disc spring outer diameter support surface 103 and an upper disc spring limit protrusion 104 . The upper disc spring notch 101 opens on the inner side of the upper disc spring 10 with an inclination of 45°. The top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com