Multifunctional anti-cracking echelette grating

An infrared grating and anti-cracking technology, which is applied in the field of multi-functional anti-cracking infrared gratings, can solve the problems of key circuit exposure, cracking, and thinness, and achieve the effect of excellent rain resistance and simplified installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

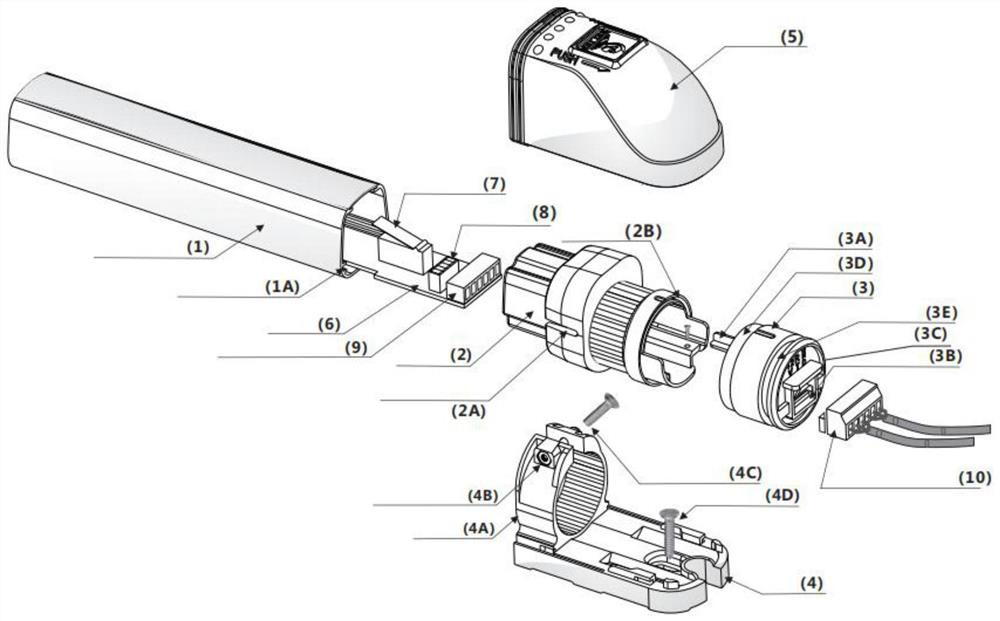

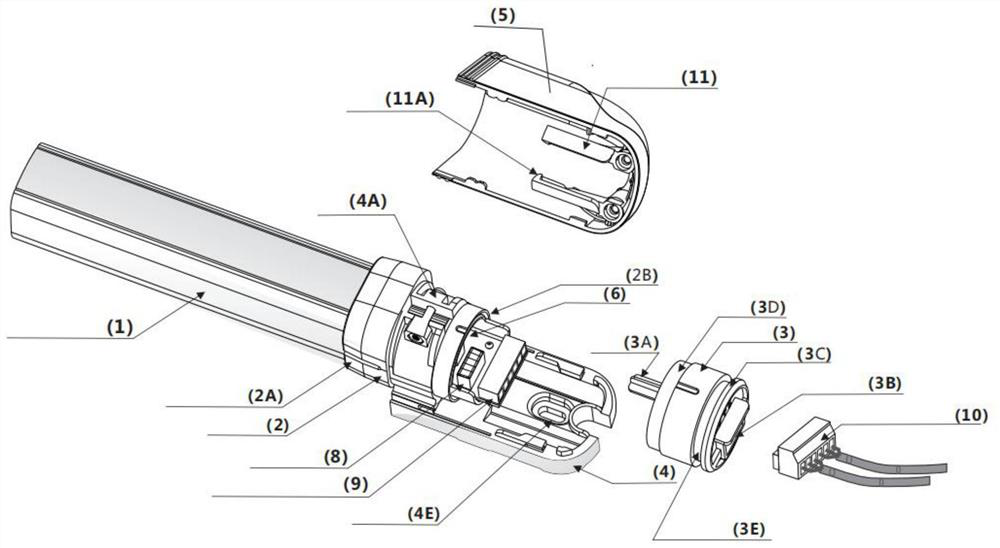

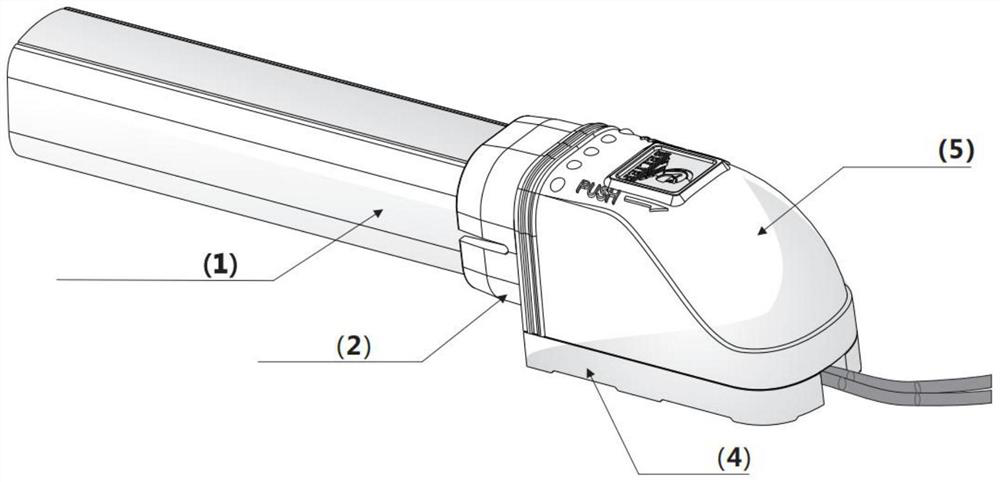

[0026] Embodiment: A specific embodiment of the present invention. A multifunctional anti-cracking infrared grating includes an aluminum alloy pipe rod 1, a pipe rod plug 2, an inner protective shell 3, a base 4, an outer protective shell 5, a circuit board 6, a tamper-resistant switch 7, Jumper plug 8, plug-in wiring socket 9, plug-in wiring plug 10, linkage claw hook 11 and external lead wire 12, such as figure 1 and figure 2In this embodiment, the pipe rod plug 2 is at the position of the central hub, the front jaw groove 2A of the front end of the pipe rod plug 2 is tightly connected with the aluminum alloy pipe rod 1, the middle section is connected with the locking buckle 4A of the base 4, and the rear The rear jaw groove 2B at the end is tightly connected with the inner protective shell 3, the cavity is a middle-pass structure, the circuit board 6 passes through the pipe rod plug 2, and the circuit board 6 is fixedly connected with the pipe rod plug 2 with screws, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com