A kind of automatic production system and method for protective fence

A production system and fence technology, applied in the field of automated production systems, can solve the problems of poor quality controllability of parts, many production processes, and high labor costs, and achieve the effects of improving productivity, solving many processes, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

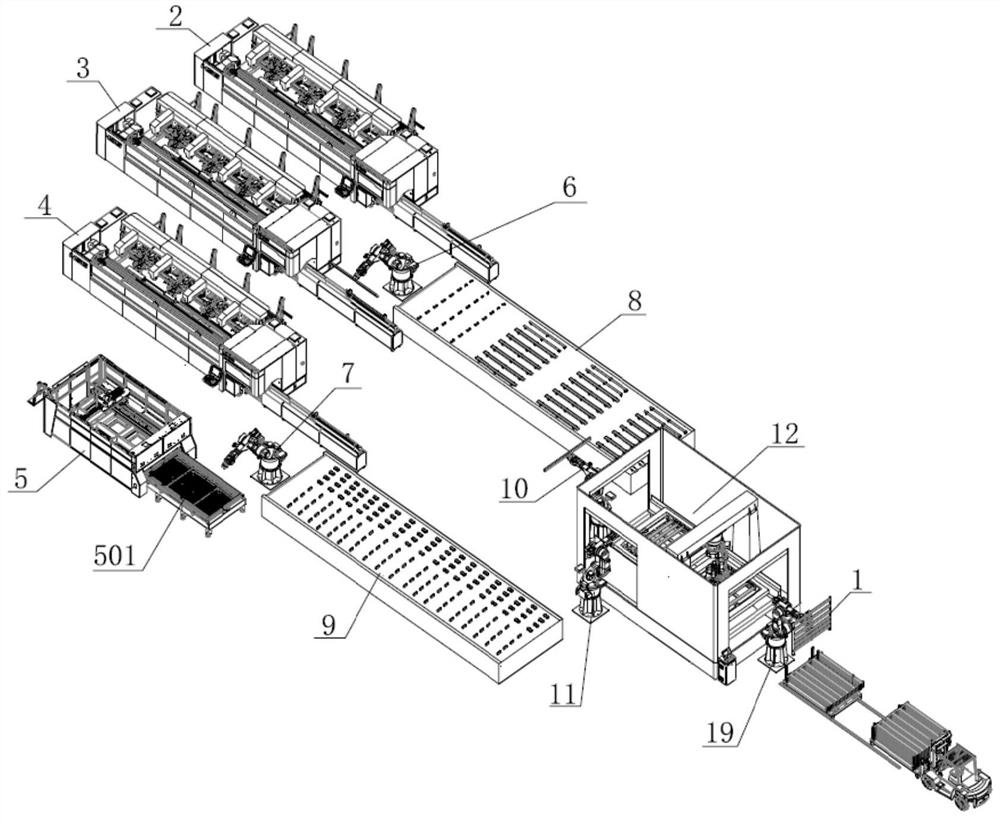

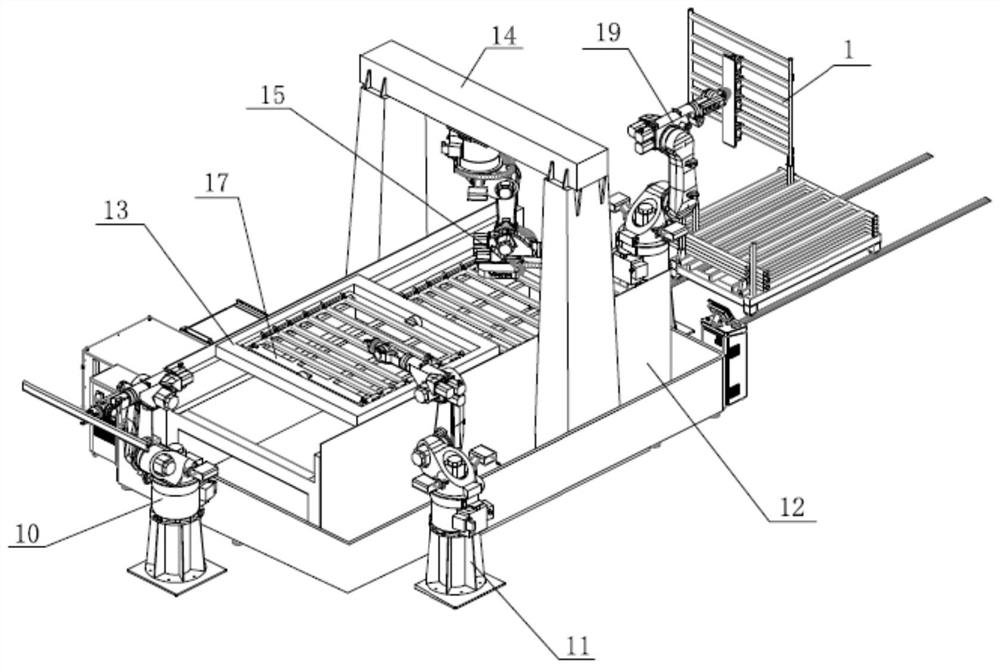

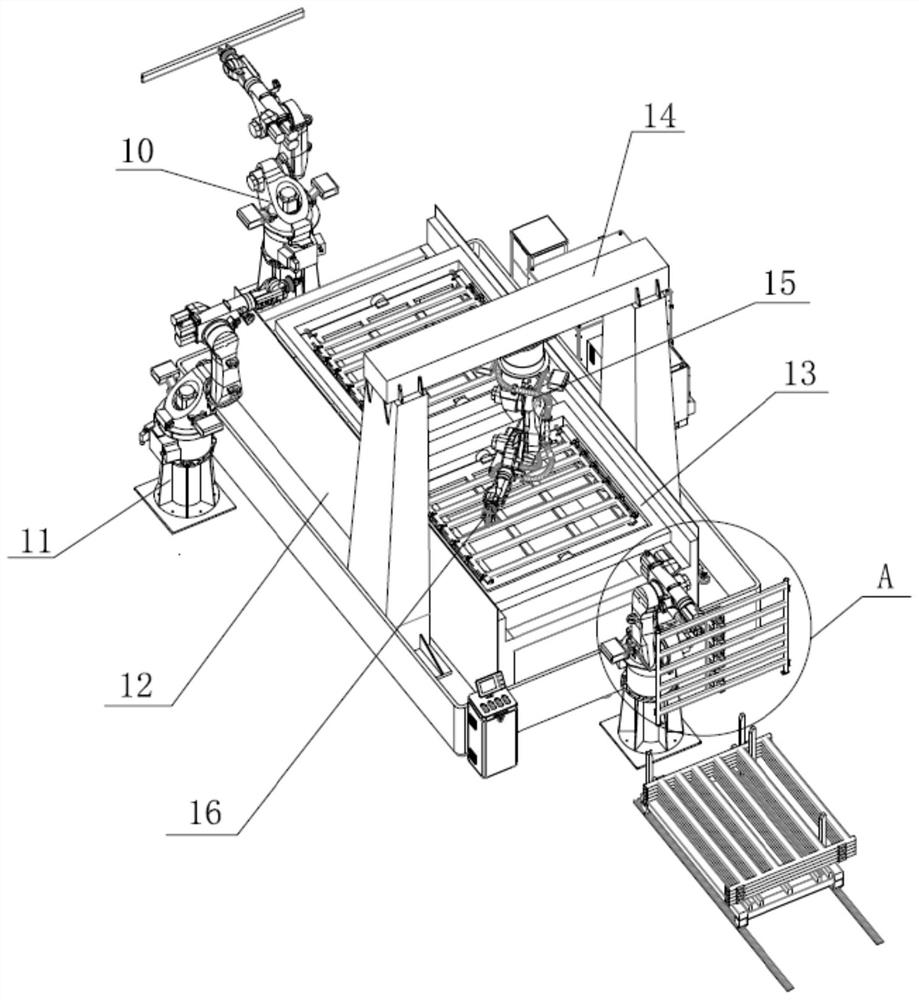

[0039] like Figure 1-Figure 5 As shown in the figure, an automated production system for a protective fence, the composition of the protective fence 1 includes a first pipe fitting 101, a second pipe fitting 102, a third pipe fitting 103 and a grounding flange 104, the automated production system includes a pipe cutting device, a cutting Board device 5, feeding device, loading device, assembling and welding device 12, unloading device and control device electrically connected to the above devices;

[0040] The control device is used to control the action execution of the pipe cutting device, the plate cutting device 5, the feeding device, the feeding device, the assembling and welding device 12, and the unloading device;

[0041] The pipe cutting device adopts a laser pipe cutting machine, and the pipe cutting device includes a first pipe cutting device 2 for cutting pipes to generate a first pipe part 101, a second pipe cutting device 3 for generating a second pipe part 102,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com