Bridge crane installation construction method

A technology of bridge crane and construction method, which is applied in the directions of portable lifting device, hoisting device, transportation and packaging, etc., can solve the problems of long construction time and many drilling holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

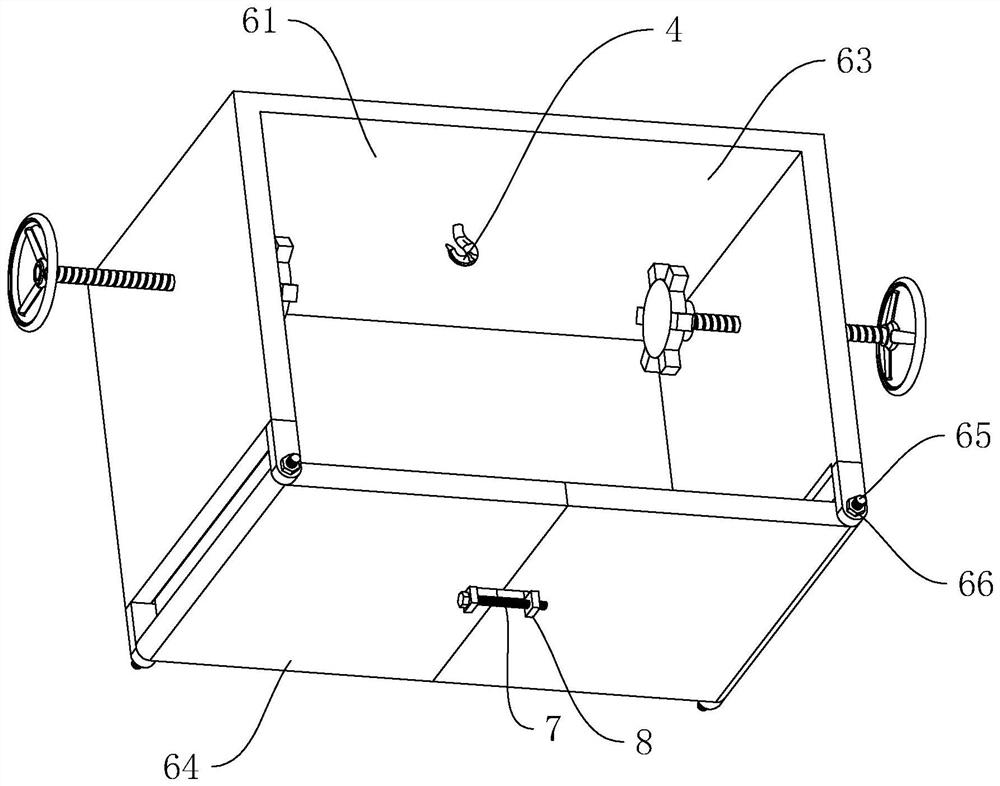

[0039] The following is attached Figure 1-5 The application is described in further detail.

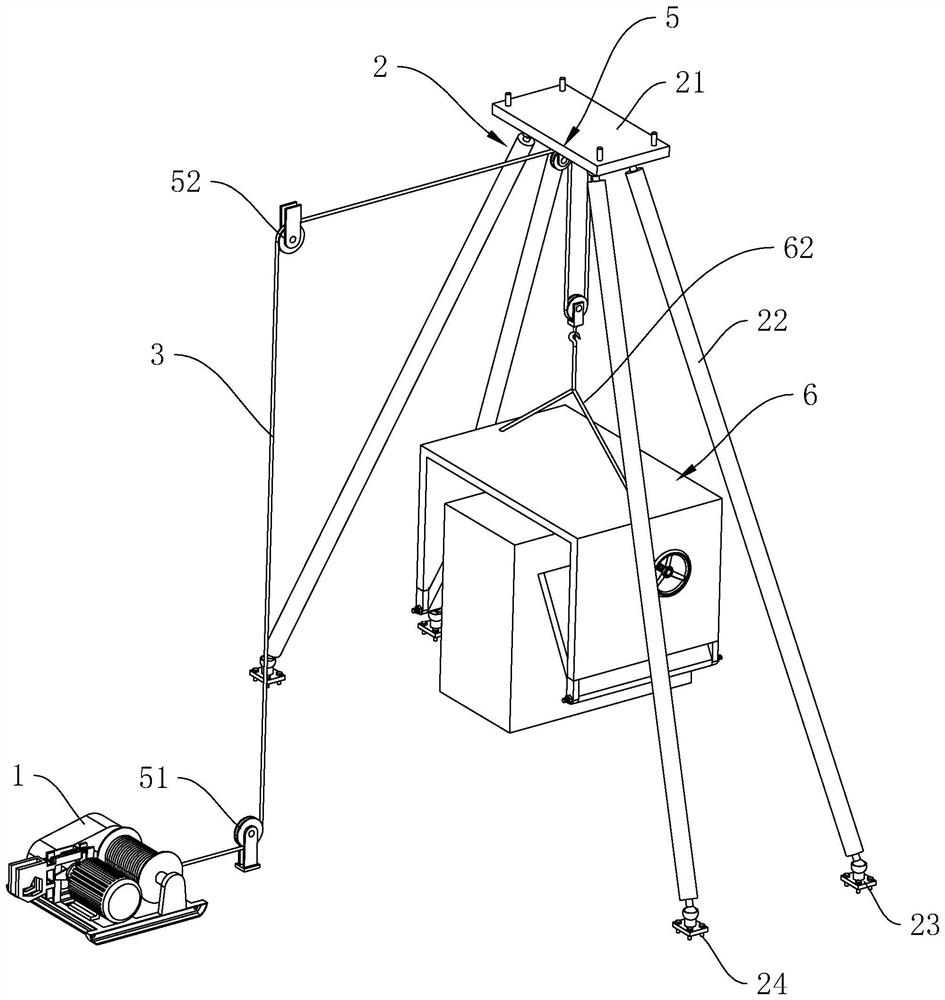

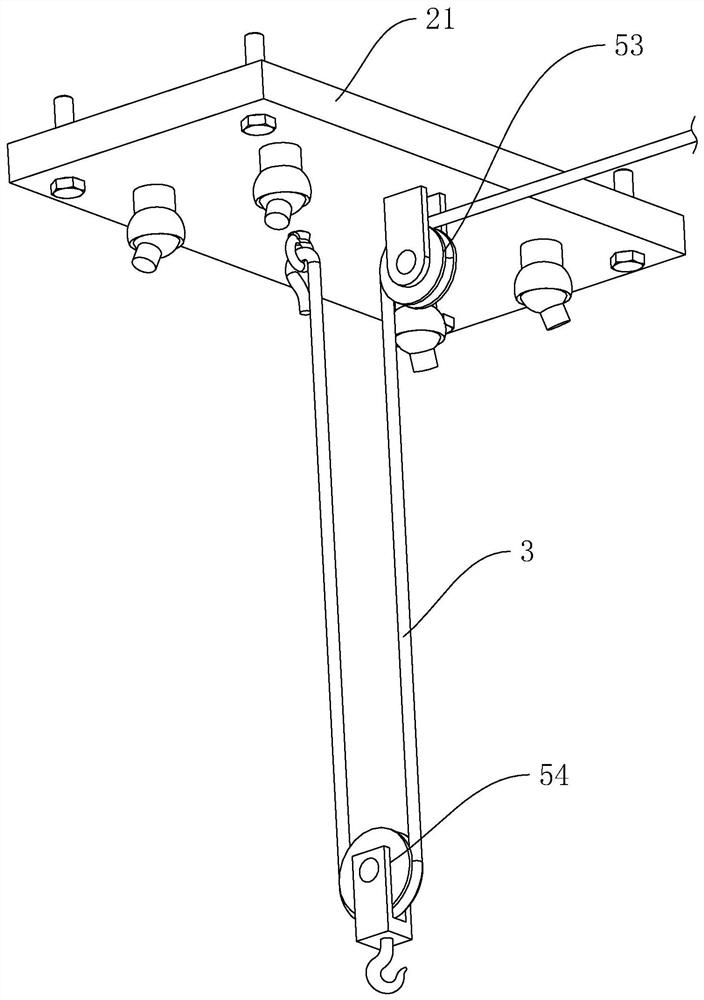

[0040] On the one hand, the embodiment of the present application discloses a bridge crane construction hoisting system, refer to figure 1 , including a support assembly and a traction assembly, the support assembly serves as a fulcrum, and the components of the crane can be hoisted by the traction assembly.

[0041] The support assembly includes a support frame 2, the support frame 2 includes a lifting point anchor plate 21 and a leg 22 connected with the lifting point anchor plate 21, one end of the leg 22 is hinged with the lifting point anchor plate 21, and the number of legs 22 is at least three group, the number of supporting legs 22 in this embodiment is four groups, so that it is difficult to topple over during the hoisting process.

[0042] One end of the support leg 22 far away from the anchor plate 21 of the lifting point has a support seat 23, and the support seat 23 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap