Medical adhesive capable of promoting wound healing and preparation method therefor

A wound healing and adhesive technology, which is applied in the field of medical adhesives for promoting wound healing and its preparation, can solve the problem of low adhesive strength and the like, achieves low equipment requirements, is suitable for large-scale production, and is well biodegradable. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 3g of polylactic acid and 0.5g of Mrcp-20k protein isolated from barnacle gum, add 100mL of deionized water and disperse under the condition of heating and stirring at 60°C;

[0028] (2) After cooling down to room temperature, 1 g of lectin and 1 g of snail mucus (collected by oneself) were added, stirred to obtain a medical adhesive, and stored at 4°C until use.

Embodiment 2

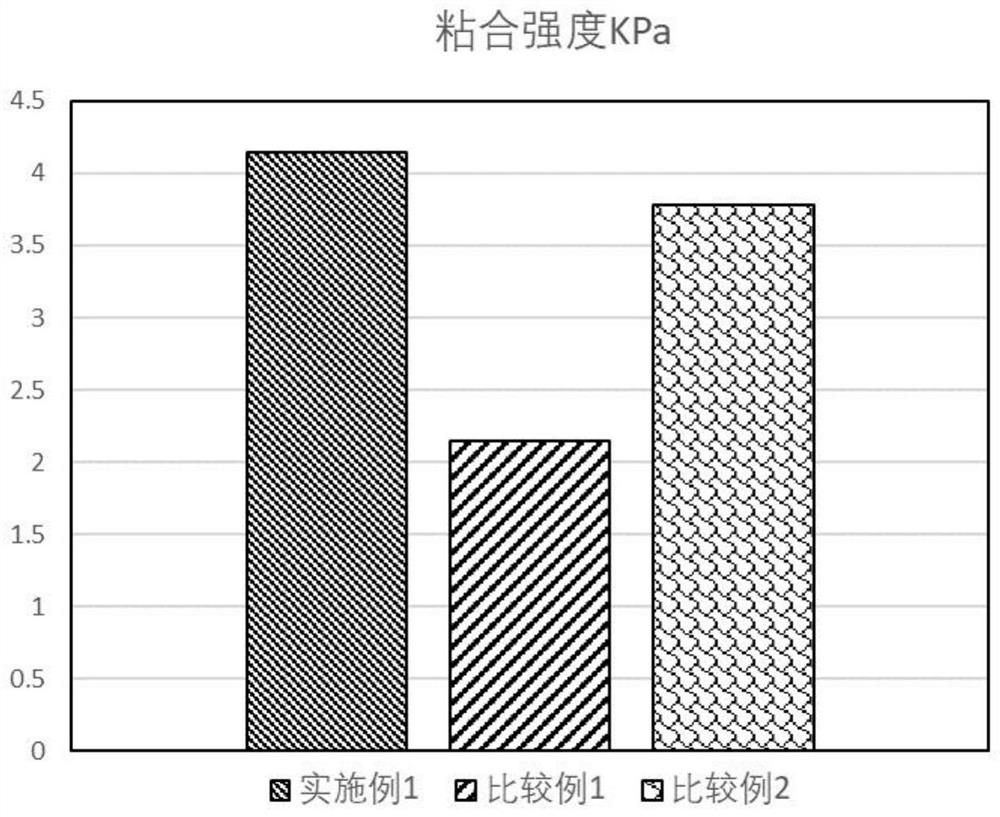

[0033] Embodiment 2: Adhesive strength test and comparison

[0034] Adhesive strength test method: The treated pigskin is thawed in a 37°C water bath, cut into 1×4cm 2 For the sample, the surface moisture was fully absorbed with absorbent paper and kept at 37°C. The medical adhesive made in embodiment 1 and comparative example 1,2 is coated on pigskin surface (1 * 3cm 2 ), glue the two pieces of pigskin together, lightly press them with your fingers for 30 seconds, keep them warm in a water bath at 37°C, and test the uniaxial tensile stress of the sample on a universal mechanical testing machine with a 50N load cell at a crosshead rate of 5mm / min- Strain test. Each stretch to break as the final maximum adhesive force, calculate the corresponding adhesive strength, the results are as follows figure 1 shown. It can be seen from the figure that the addition of Mrcp-20k protein helps to increase the adhesive strength of the adhesive, and the combination of Mrcp-20k protein an...

Embodiment 3

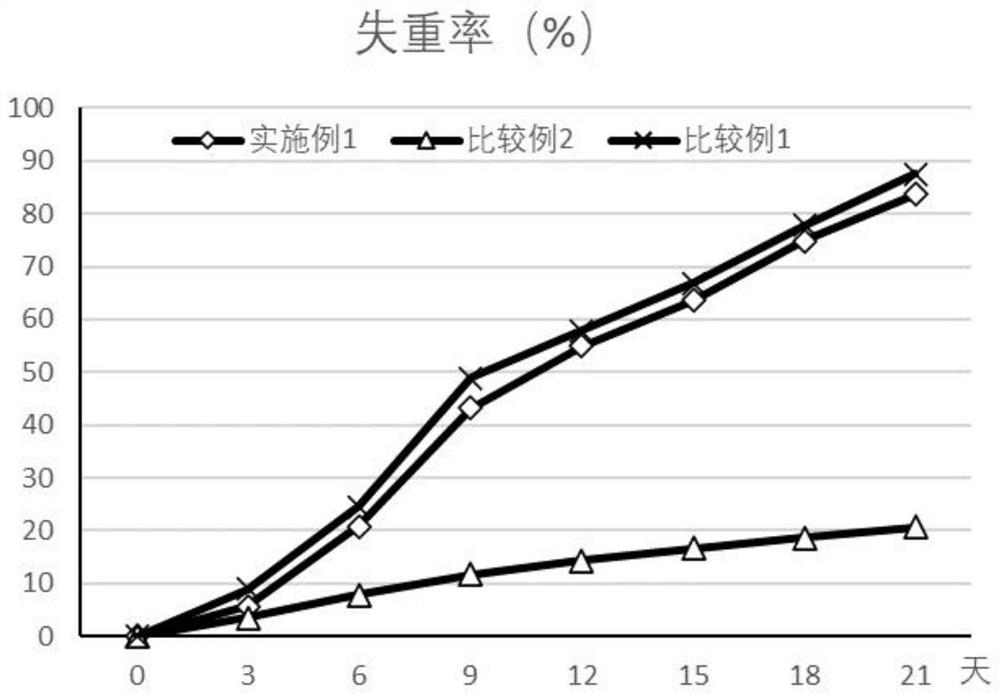

[0035] Embodiment 3: in vitro degradation experiment

[0036] The adhesives prepared in Example 1 and Comparative Examples 1 and 2 were freeze-dried, and the freeze-dried adhesives were soaked in Tris buffer, placed in a constant temperature shaking box (37°C, 80r / min), measured and calculated The weight loss rate was used to characterize the in vitro degradation performance. Shake well at 37°C and 100rpm / min, then take out some samples at 3, 6, 9, 12, 15, 18 and 21 days respectively, vacuum dry at 60°C to constant weight, weigh and calculate the concentration of the taken out samples W i . W 0is the concentration of the original lyophilized binder. Then the weight loss rate (%) is calculated according to the formula:

[0037] Weight loss rate (%)=(W0-Wi) / (W0)×100.

[0038] The results of the in vitro degradation experiments of the adhesive are as follows: figure 2 Shown: the in vitro degradation test result of adhesive of the present invention is as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com