Shielding structure of connector assembly

一种组件、屏蔽壁的技术,应用在连接部件保护接地/屏蔽装置、连接装置的零部件、连接等方向,能够解决连接器性能降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

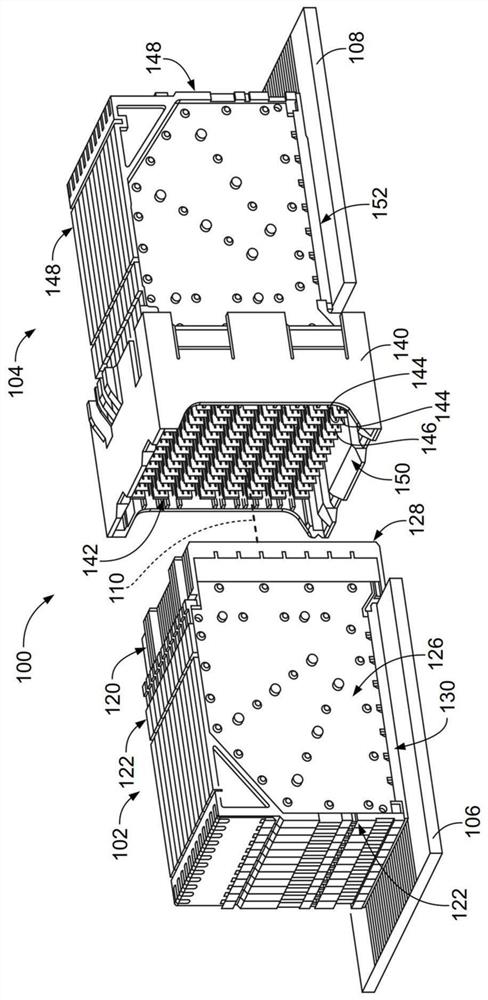

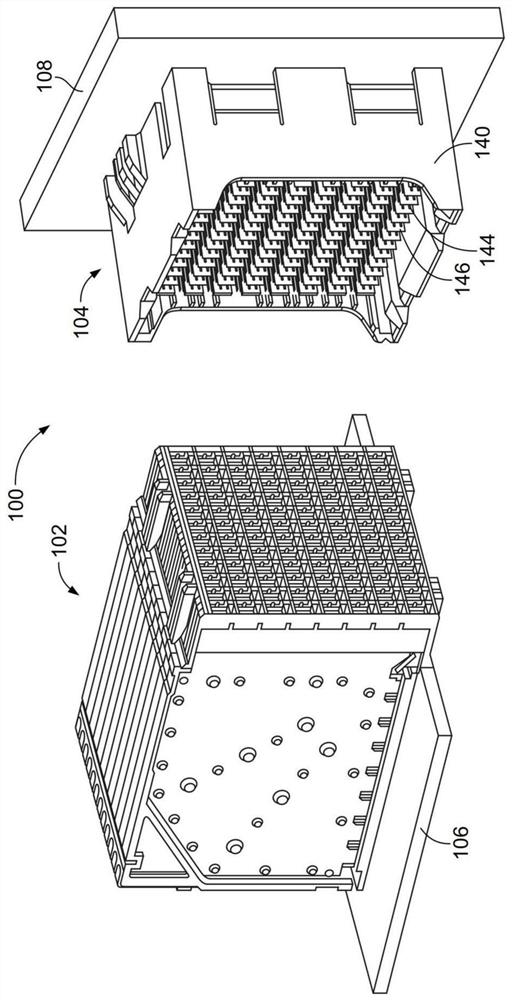

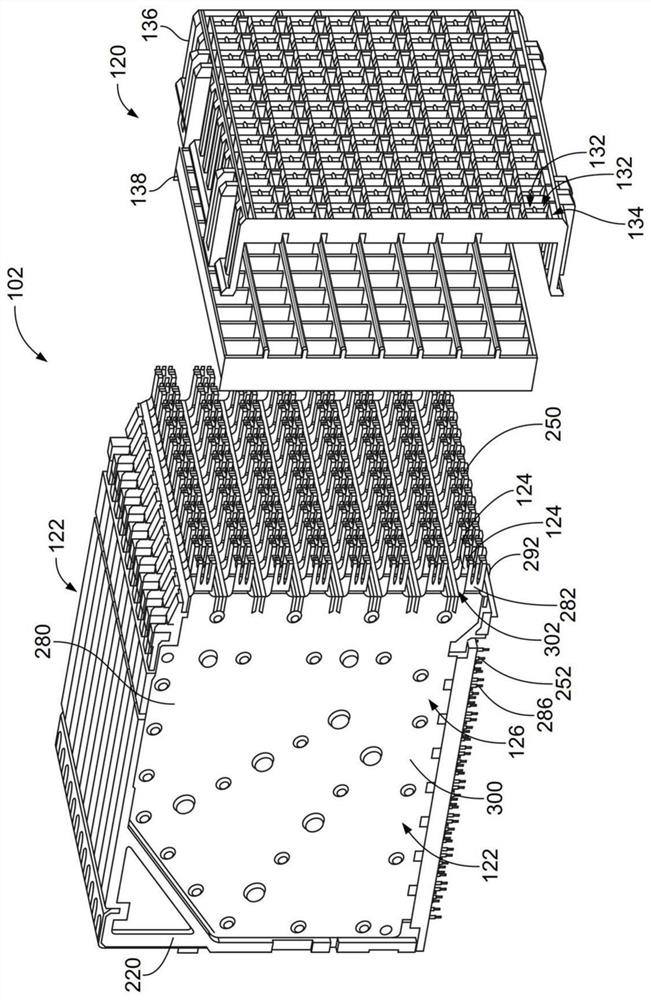

[0018] figure 1 is a perspective view of an exemplary embodiment of an electrical connector system 100 showing a first connector assembly 102 and a second connector assembly 104 that may be mated directly together. The first connector assembly 102 and / or the second connector assembly 104 may be referred to hereinafter individually as a "connector assembly" or collectively as a "connector assembly". The first connector assembly 102 is a receptacle assembly, and may hereinafter be referred to as the receptacle assembly 102 . The second connector assembly 104 is a header assembly and may be referred to as header assembly 104 hereinafter. The mating axis 110 extends through the first connector assembly 102 and the second connector assembly 104 . The first connector assembly 102 and the second connector assembly 104 are mated together in a direction parallel to and along the mating axis 110 .

[0019] In the exemplary embodiment, the first connector assembly 102 and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com