Method and system for preparing alternative fuel by using aluminum electrolysis cell overhaul slag

A technology that replaces fuel and aluminum electrolyzer, applied in the direction of fuel, solid fuel, waste fuel, etc., can solve the problems of high energy consumption of mills, difficult pretreatment, low replacement rate, etc., to improve product fineness and output of fine products , Increase the calorific value and volatile content, reduce the effect of transportation and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

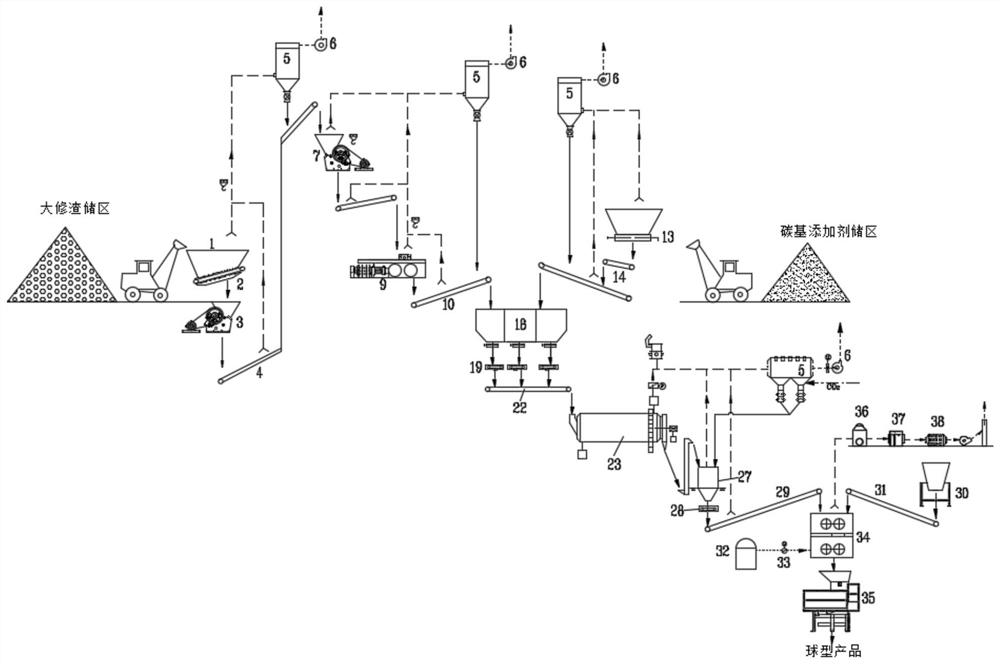

Method used

Image

Examples

Embodiment 1

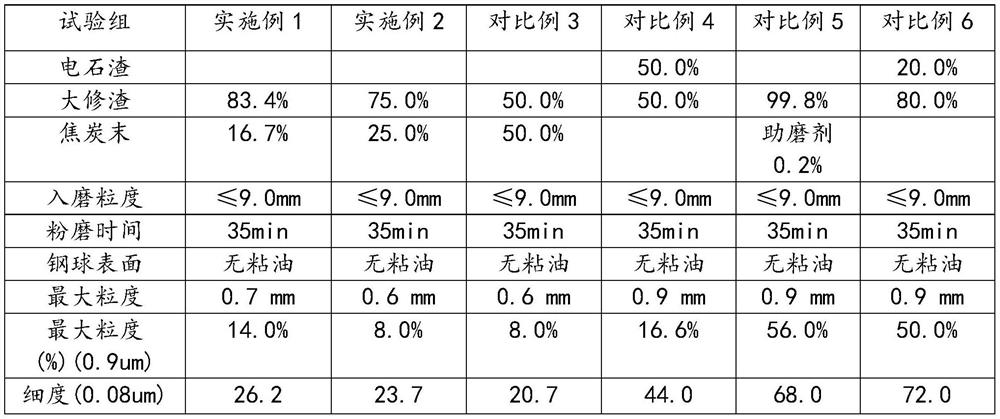

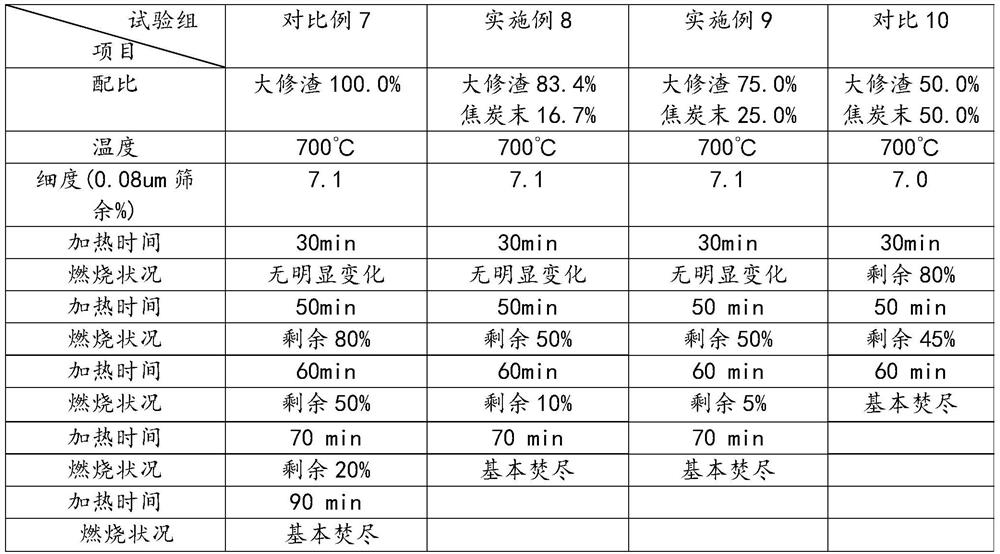

[0093] Using the system and preparation method of the present invention, the overhaul slag is crushed through a three-stage crushing process to obtain small particles with a particle size of ≤9mm; coke powder is used as the grinding aid, and the particle size of the coke powder is ≤9m, wherein the small particles: coke powder It is 83.4:16.7; the maximum particle size after modified grinding is 0.7mm.

Embodiment 2

[0095] Using the system and preparation method of the present invention, the overhaul slag is crushed through a three-stage crushing process to obtain small particles with a particle size of ≤9mm; coke powder is used as the grinding aid, and the particle size of the coke powder is ≤9m, wherein the small particles: coke powder It is 75:25, and the maximum particle size after modified grinding is 0.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com