Synthesis method and application of 1, 3-bis (isocyanate alkyl)-1, 1, 3, 3-tetramethyldisiloxane

A technology of tetramethyldisiloxane and alkyl carbamate silane, which is applied in the field of compound synthesis, can solve the problems of low yield of alkyl carbamate, difficult separation of products, large amount of raw materials, etc., so as to reduce the input of raw materials. The effect of cost, short synthesis time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of synthetic method of 1,3-bis(isocyanatoalkyl)-1,1,3,3-tetramethyldisiloxane, the steps are as follows:

[0032] The first step: chloropropyldimethylmethoxysilane, sodium cyanate and methanol were reacted at 130° C. and a pressure of 0.1 MPa for 13 hours at a molar ratio of 1:2.5:3 to synthesize methyl carbamate silane.

[0033] The second step: Add methyl carbamate silane dropwise to water at 80°C for hydrolysis, wherein the volume ratio of water to methyl carbamate silane is 3:1, to obtain 1,3-bis(carbamate methyl propyl base)-1,1,3,3-tetramethyldisiloxane, the end of the dropwise addition means the end of the second step reaction.

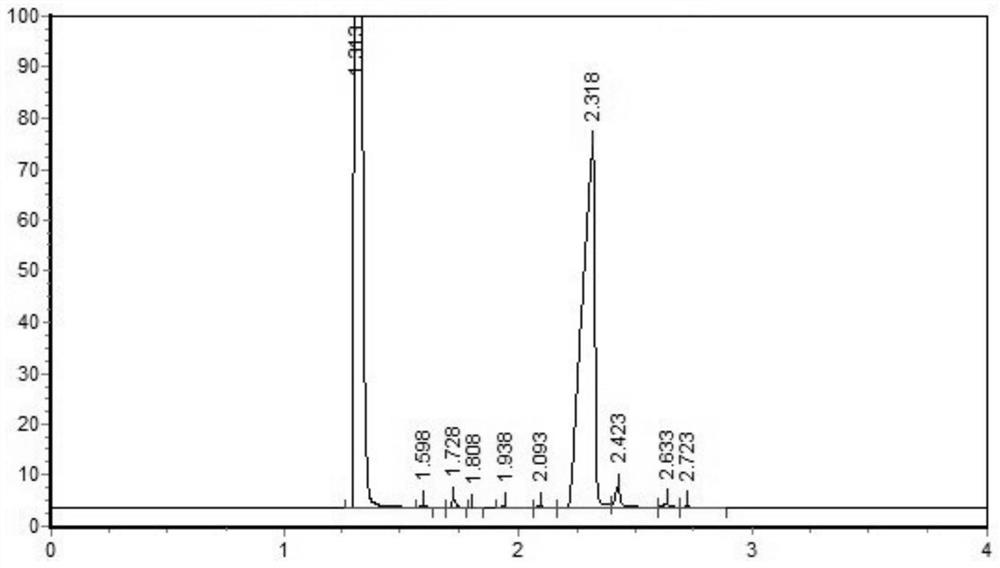

[0034] The third step: first add triethylamine to 1,3-bis(carbamate propyl)-1,1,3,3-tetramethyldisiloxane, and then add Add trimethylchlorosilane dropwise to 1,3-bis(carbamate propyl)-1,1,3,3-tetramethyldisiloxane, and the addition is completed in 4 hours to obtain trimethylsilyl methyl carbamate silane. Wherein, the molar rati...

Embodiment 2

[0037] A kind of synthetic method of 1,3-bis(isocyanatoalkyl)-1,1,3,3-tetramethyldisiloxane, the steps are as follows:

[0038] The first step: chloropropyldimethylmethoxysilane, potassium cyanate and ethanol were reacted at 180° C. and a pressure of 0.2 MPa for 11 hours at a molar ratio of 1:2.5:3 to synthesize urethane silane.

[0039] The second step: Add urethane silane dropwise to water at 100°C for hydrolysis, wherein the volume ratio of water to urethane silane is 5:1.5 to obtain 1,3-bis(urethane propyl base)-1,1,3,3-tetramethyldisiloxane, the end of the dropwise addition means the end of the second step reaction.

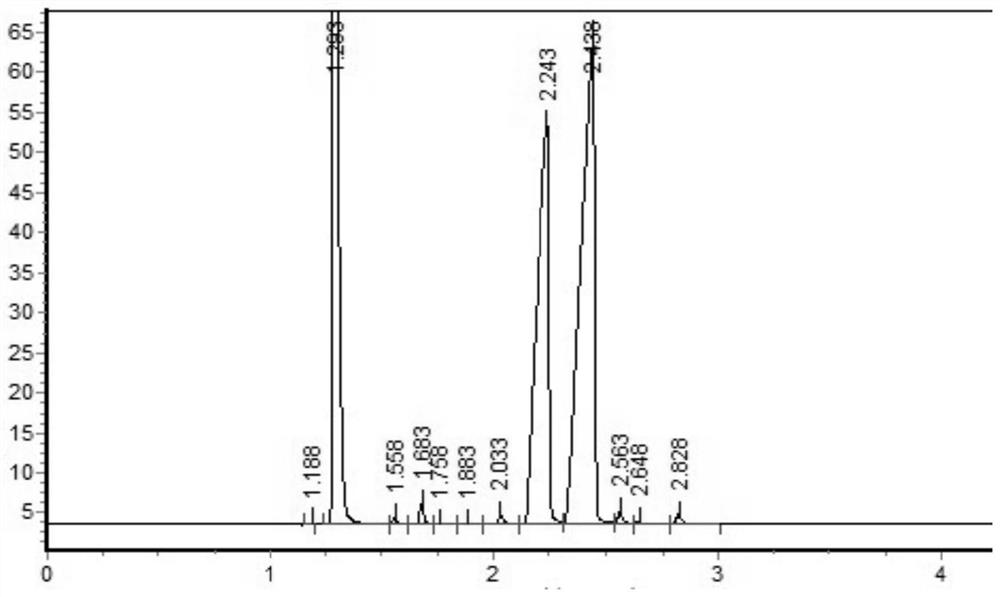

[0040] The third step: first add triethylamine to 1,3-bis(carbamate ethyl propyl)-1,1,3,3-tetramethyldisiloxane, and then add triethylamine to 1 at 50°C , 3-bis(carbamate ethyl propyl)-1,1,3,3-tetramethyldisiloxane was added dropwise with trimethylchlorosilane, and the addition was completed in 4 hours to obtain trimethylsilyl carbamic acid ethyl silane. ...

Embodiment 3

[0043] A kind of synthetic method of 1,3-bis(isocyanatoalkyl)-1,1,3,3-tetramethyldisiloxane, the steps are as follows:

[0044] The first step: chloropropyldimethylethoxysilane, magnesium cyanate and tert-butanol were reacted at 80°C and a pressure of 0.1MPa for 14 hours at a molar ratio of 1:2.5:3 to synthesize tert-butyl carbamate silane.

[0045] Step 2: Add tert-butyl carbamate silane dropwise to water at 25°C for hydrolysis, wherein the volume ratio of water to tert-butyl carbamate silane is 4:1 to obtain 1,3-bis(tert-butyl carbamate Butylcarboxypropyl)-1,1,3,3-tetramethyldisiloxane, the end of the dropwise addition means the end of the second step reaction.

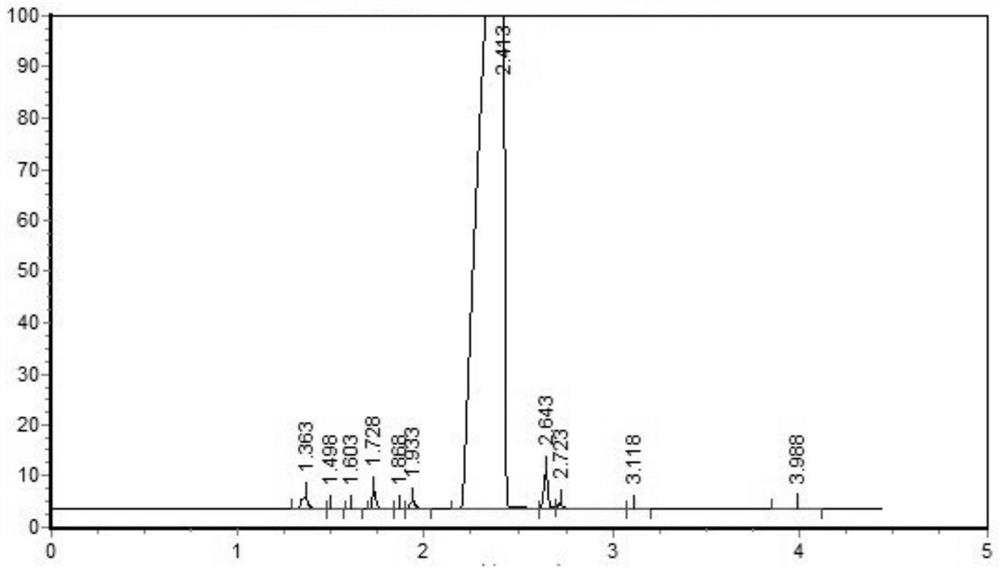

[0046]The third step: first add triethylamine to 1,3-bis(tert-butylcarbamate propyl)-1,1,3,3-tetramethyldisiloxane, and then Add trimethylchlorosilane dropwise to 1,3-bis(tert-butylcarbamate propyl)-1,1,3,3-tetramethyldisiloxane, and the addition is completed in 4 hours to obtain trimethyl Silyl tert-butyl carbama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com