Bag making machine

A bag-making machine and body technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of easy deviation of the bag body, waste of resources, and positioning of the bag body, so as to improve the scope of application, save resources, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

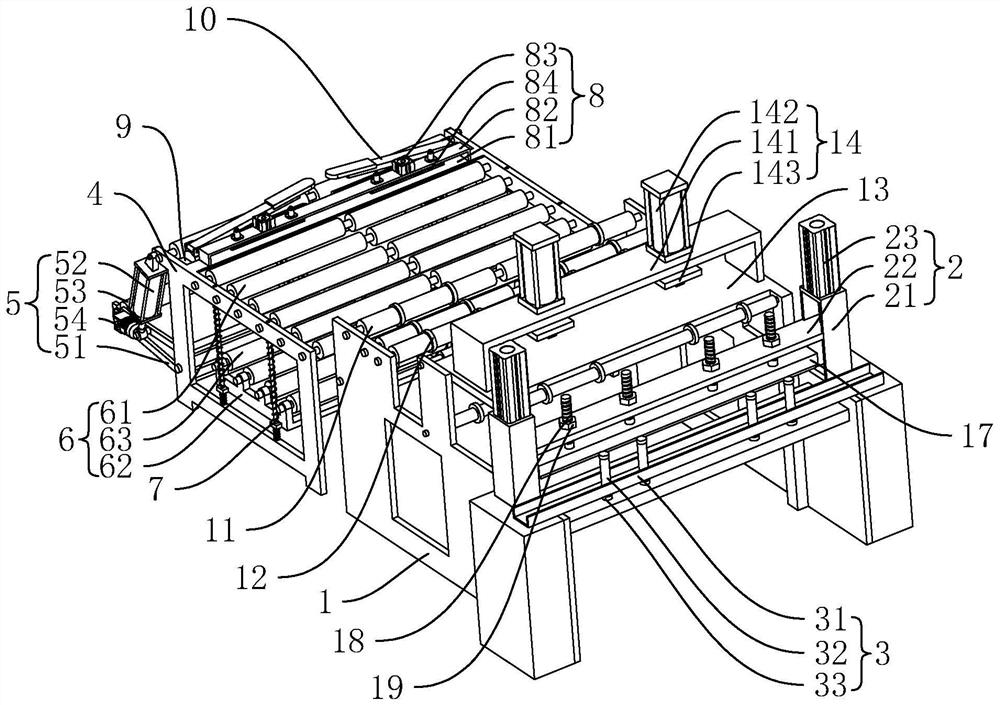

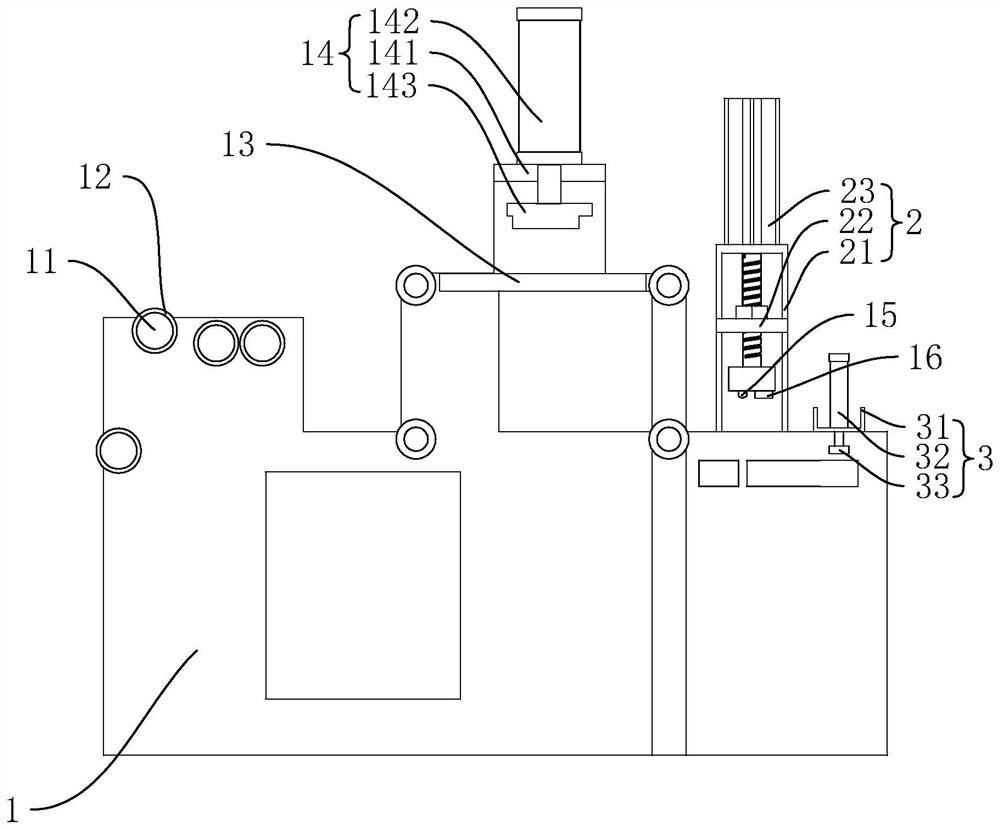

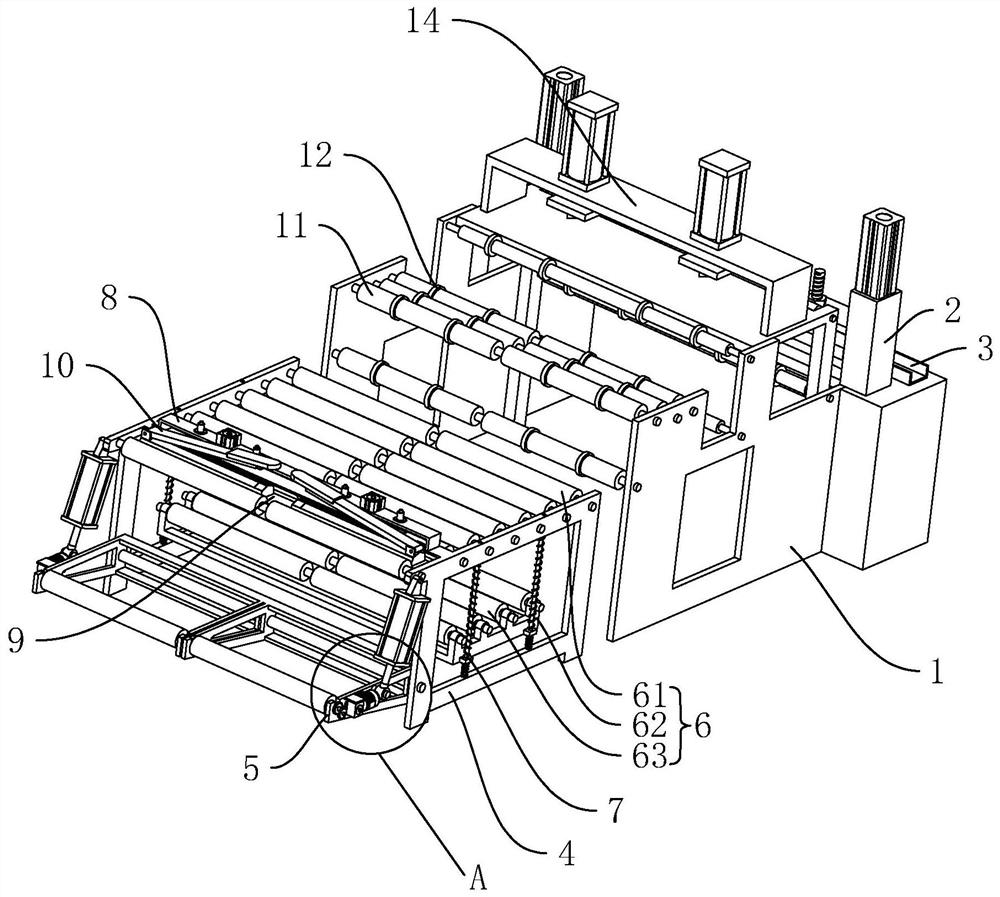

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses a bag making machine, referring to figure 1 and figure 2 , including a body 1, a cutting device 2 is installed on the body 1, and the cutting device 2 includes a cutting frame 21 installed on the body 1, and two cutting frames 21 are respectively installed at both ends of the body 1 in the width direction, and two The sliding table 22 is set between the cutting frames 21, and the sliding table 22 slides towards or away from the body 1. The driving part 23 is installed on the cutting frame 21. The driving part 23 is a driving cylinder, and the driving part 23 is connected The sliding table 22 drives the sliding table 22 to slide. The sliding table 22 is equipped with an adjustment block 17 facing the side of the body 1. The adjusting block 17 is fixedly equipped with a cutter 15 and a heat-sealing strip 16. The adjusting bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap