A method for calibrating DC parameters of multiple test channels of a semiconductor testing machine

A technology for testing channels and DC parameters, which is applied in the direction of single semiconductor device testing, measuring electronics, measuring devices, etc., can solve the problems of not being able to better realize the synchronization and timeliness of multiple testing channels, and achieve the solution of DC parameter calibration problem, effect of satisfying synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

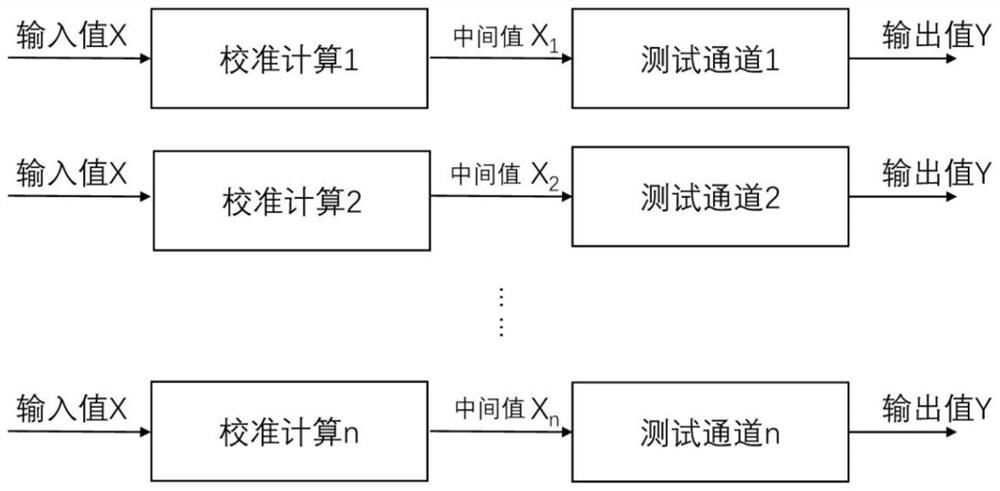

[0070] The operating modes of the 8 power supply test channels of the semiconductor testing machine in this embodiment are set to the forward current output mode, and then the 8 power supply test channels are calibrated, specifically including the following steps:

[0071] S1, connect the input ends of the 8 power supply test channels to a linear operation circuit of model AD5560, and then connect the input ends of the 8 linear operation circuits to a nonlinear operation software.

[0072] S2, according to the input digital value-output current value of the 8 power supply test channels, obtain the nonlinear transformation formula in the nonlinear computing software:

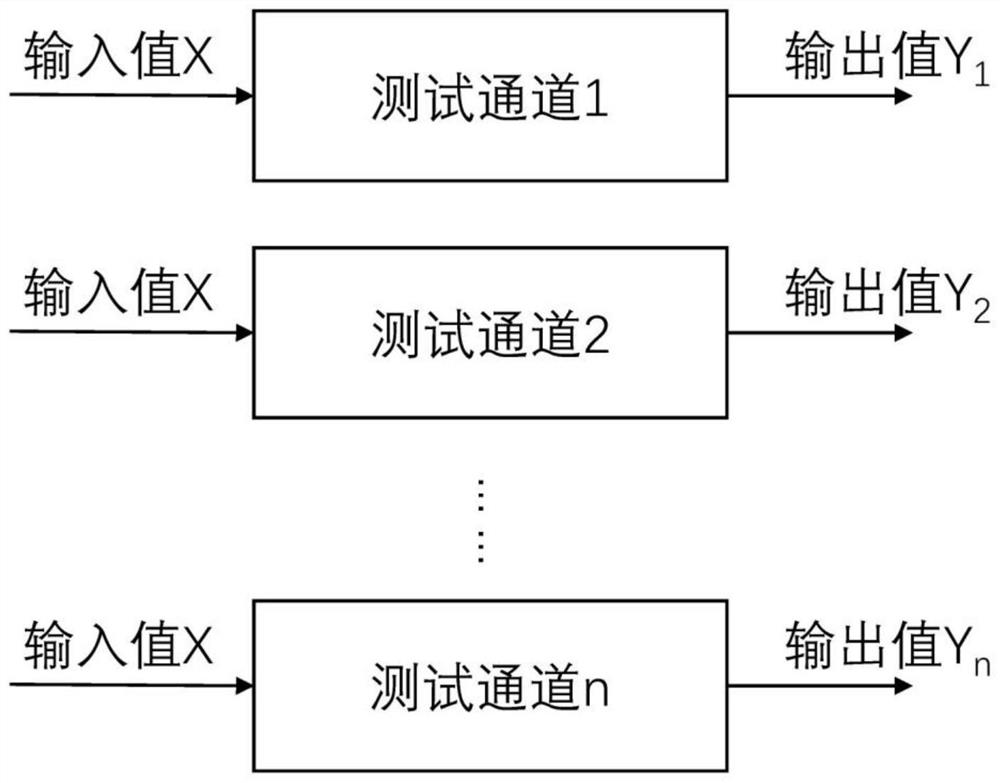

[0073] S21, input the same input digital value X to the 8 power supply test channels, and measure the output current value Y of the 8 power supply test channels n , and find the average of the output values of all channels to be calibrated ;

[0074] S22, set each input digital value X s For different value...

Embodiment 2

[0097] The operating modes of the 8 power supply test channels of the semiconductor testing machine in this embodiment are set to negative current output mode, and then the 8 power supply test channels are calibrated, specifically including the following steps:

[0098] S-1, connect the input ends of 8 power supply test channels to a linear operation circuit of model AD5560, and then connect the input ends of the 8 linear operation circuits to a nonlinear operation software.

[0099] S-2, according to the input digital value-output current value of the 8 power supply test channels, obtain the nonlinear transformation formula in the nonlinear computing software:

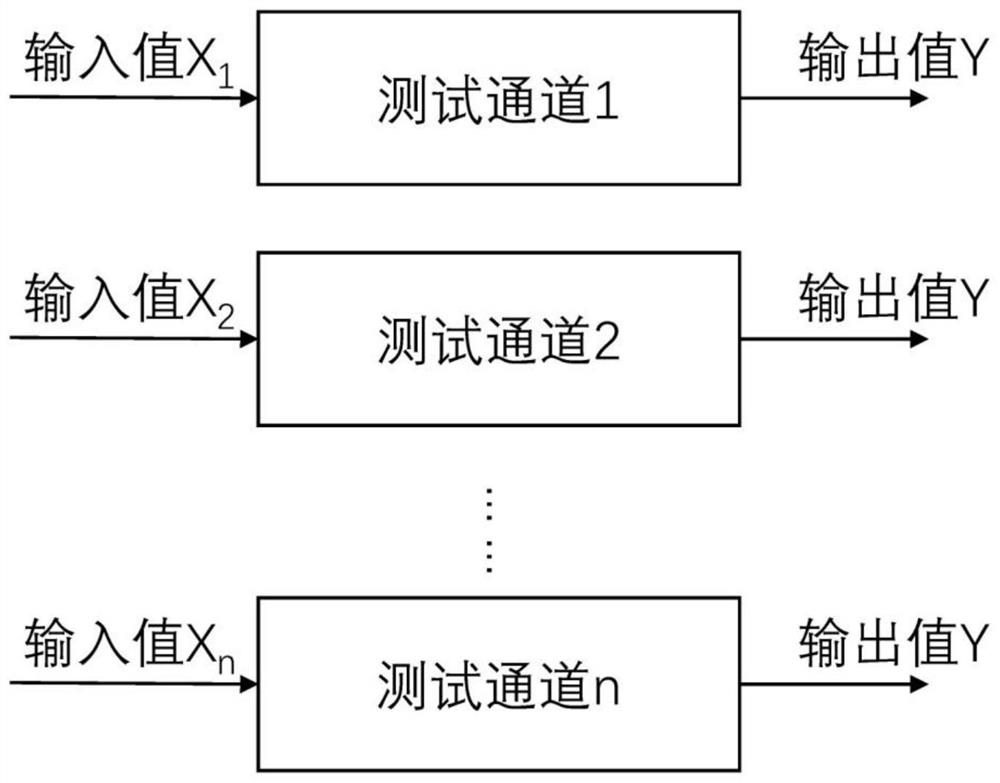

[0100] S-21, select the power supply test channel 1 as the standard channel, and input 32 input values A to the standard channel in sequence s , and set 32 input values A s For different values, measure the output value B of the standard channel each time s , summarize the obtained data into a table, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com