A kind of antistatic powder coating and preparation method thereof

A powder coating and anti-static technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problems of poor filler acceptance, reduced weather resistance, and insufficient dispersion of anti-static powder coating raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

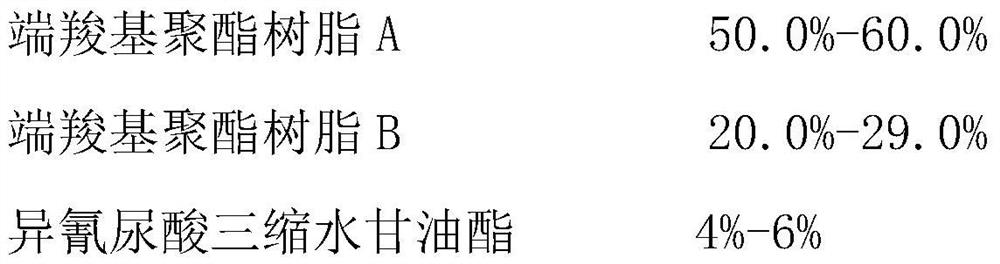

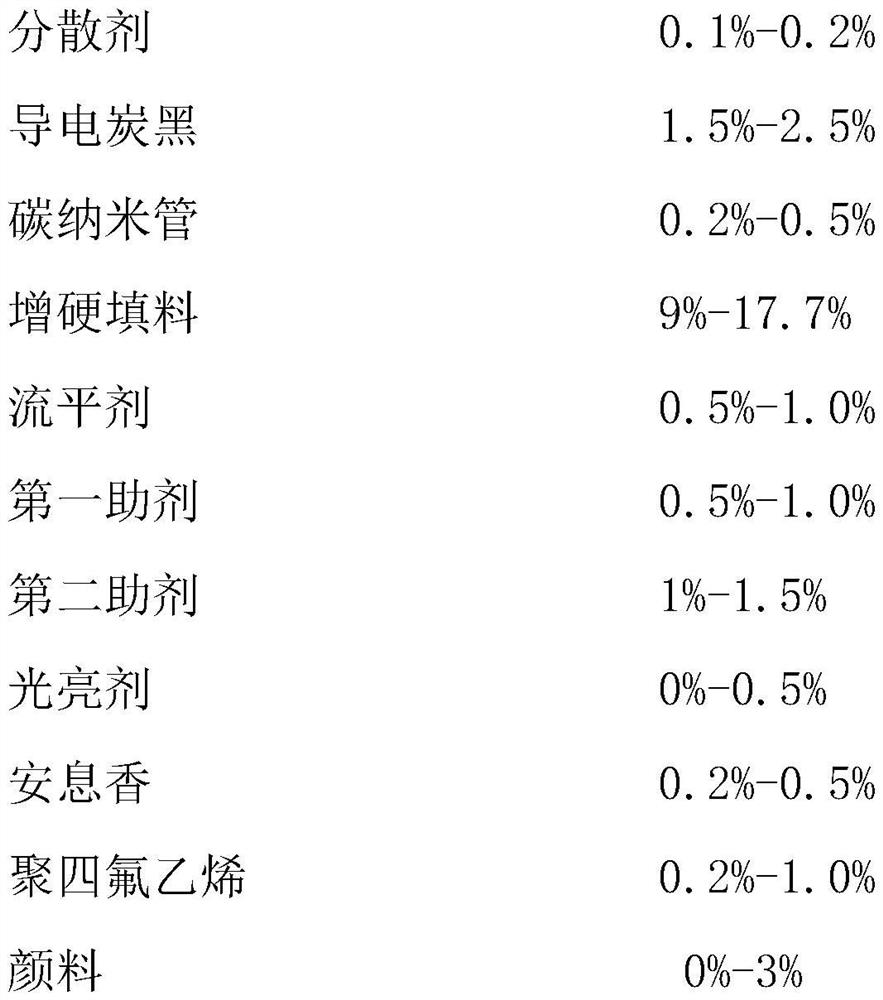

[0044] In one of the embodiments, a preparation method of the antistatic powder coating is also provided, the method comprising the following steps:

[0045]Put the hardening filler in the mixing kettle, then add the second auxiliary, after fully mixing and evenly placing it in a medium water bath at a temperature of 65℃-85℃, after vibrating for 8min-15min, extrude under the pressure of 45MPa-55MPa treatment, and finally obtain mixture A through the first crushing treatment;

[0046] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, 1. Auxiliary, brightener, benzoin, polytetrafluoroethylene and pigment, fully mixed to obtain mixture B;

[0047] The mixture B is subjected to melt extrusion treatment, second crushing treatment and pulverizing treatment to obtain an antistatic powder coating.

[0048] In one embodiment, t...

Embodiment 6-8

[0087] A kind of preparation method of antistatic powder coating in embodiment 6-8, comprises the following steps:

[0088] Place the modified wax and the carboxylic acid derivative in a mixing kettle, and stir at a stirring speed of 1000 r / min for 15 minutes to obtain a uniformly dispersed second auxiliary agent;

[0089] Place the hardening filler in the mixing kettle, then add the second additive, and after it is fully mixed and evenly placed in a medium water bath at a temperature of 65°C, after vibrating for 15min, extrude at 45MPa and a temperature of 85°C, and finally The mixture A is obtained through the first crushing treatment;

[0090] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, 1. Auxiliary, brightener, benzoin, polytetrafluoroethylene and pigment, fully mixed to obtain mixture B;

[0091] The mixture...

Embodiment 9-11

[0103] Place 20g of modified wax and 3g of acetic anhydride in a mixing kettle, and stir at a stirring speed of 800r / min for 15min to obtain a uniformly dispersed second auxiliary agent;

[0104] Place the hardening filler in the mixing kettle, then add the second additive, and after it is fully mixed and evenly placed in a medium water bath at a temperature of 75°C, after vibrating for 10 minutes, extrude at a temperature of 50MPa and a temperature of 75°C, and finally The mixture A is obtained through the first crushing treatment;

[0105] Continue to add carboxyl-terminated polyester resin A, carboxyl-terminated polyester resin B, triglycidyl isocyanurate, dispersant, conductive carbon black, carbon nanotubes, hardening filler, leveling agent, and the first into the mixing kettle. 1. Auxiliary, brightener, benzoin, polytetrafluoroethylene and pigment, fully mixed to obtain mixture B;

[0106] The mixture B is melt-extruded. The main machine speed of the melt-extrusion proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com