Coated base fabric for airbag and airbag including same

An airbag and base fabric technology, applied in transportation and packaging, textiles and papermaking, pedestrian/occupant safety arrangement, etc., can solve the problems of low air permeability, poor storage, and deterioration of storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

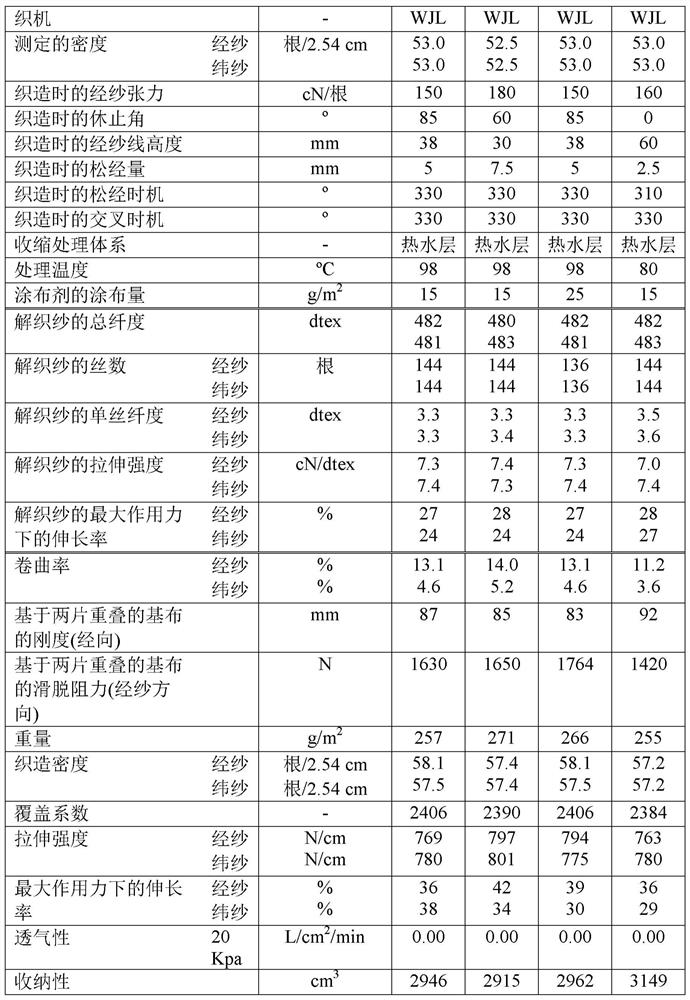

Embodiment 1

[0157] Nylon 66 raw yarn (having a circular monofilament cross-section) with a denier of 470 dtex / 144f, a tensile strength of 8.3 cN / dtex, an elongation at maximum force of 21.0%, and a boiling water shrinkage of 9.3% was used as the weft yarn and warp, using a water jet loom, by setting the weaving density of both the weft and warp to 53.0 threads / 2.54 cm, and setting the weaving conditions to those shown in Table 1, to weave a plain weave base fabric. Then, without drying, the base fabric was passed through a hot water shrink tank at 98°C, followed by a dry finishing process using a two-stage suction drum dryer in which The temperature T1 of the first step was controlled to be 120°C, and the temperature T2 of the second step was controlled to be 125°C.

[0158] Next, apply the solvent-free silicone resin composition at 15 g / m by the floating doctor blade method 2 The coating amount is applied to one surface of the base fabric. In addition, curing treatment was performed at...

Embodiment 2

[0160] Nylon 66 raw yarn (having a circular monofilament cross-section) with a denier of 470 dtex / 144f, a tensile strength of 8.3 cN / dtex, an elongation at maximum force of 21.0%, and a boiling water shrinkage of 9.3% was used as the weft yarn and warp, using a water jet loom, by setting the weaving density of both the weft and warp to 52.5 / 2.54 cm, and setting the warp tension to 180 cN / , to weave a plain weave base fabric. Then, without drying, the base fabric was passed through a hot water shrink tank at 98°C, followed by a dry finishing process using a two-stage suction drum dryer in which The temperature T1 of the first step was controlled to be 120°C, and the temperature T2 of the second step was controlled to be 125°C.

[0161] Next, apply the solvent-free silicone resin composition at 15 g / m by the floating doctor blade method 2 The coating amount is applied to one surface of the base fabric. In addition, curing treatment was performed at 190° C. for 2 minutes, where...

Embodiment 3

[0163] Nylon 66 raw yarn (having a circular monofilament cross-section) with a denier of 470 dtex / 144f, a tensile strength of 8.3 cN / dtex, an elongation at maximum force of 21.0%, and a boiling water shrinkage of 9.3% was used as the weft yarn and warp, using a water jet loom, by setting the weaving density of both the weft and warp to 53.0 threads / 2.54 cm, and setting the weaving conditions to those shown in Table 1, to weave a plain weave base fabric. Then, without drying, the base fabric was passed through a hot water shrink tank at 98°C, followed by a dry finishing process using a two-stage suction drum dryer in which The temperature T1 of the first step was controlled to be 120°C, and the temperature T2 of the second step was controlled to be 125°C.

[0164] Next, in the same manner as in Example 1, the solvent-free silicone resin composition was mixed at 25 g / m by the floating doctor method 2 The coating amount is applied to one surface of the base fabric. In addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com