Intensive energy-saving sulfur trioxide gas cooling system for sulfonation process and cooling method thereof

A sulfur trioxide and gas cooling technology, applied in the steam generation method using heat carrier, heat exchanger type, fixed tubular conduit assembly, etc., can solve the problem of discounted heat recovery effect, low heat exchange efficiency, and gas-gas exchange Problems such as large heat transfer resistance, etc., achieve the effect of improving operational safety, improving steam grade, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

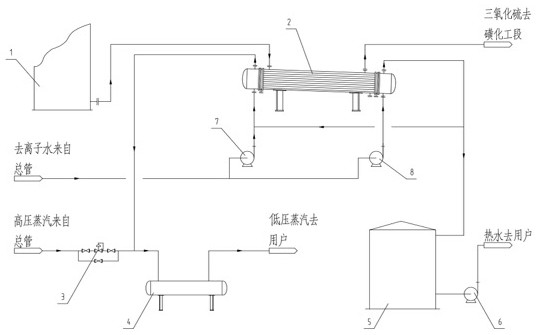

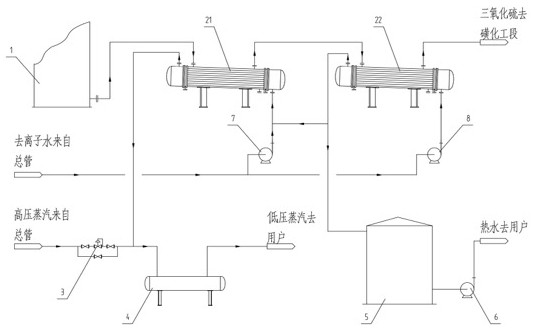

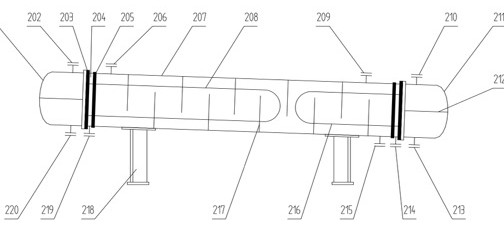

[0032] The intensive and energy-saving sulfur trioxide gas cooling system used in the sulfonation process described in this embodiment includes a sulfur trioxide conversion tower outlet 1 and a sulfur trioxide heat recovery device 2, and the sulfur trioxide heat recovery device 2 consists of the first A heat recovery device formed by connecting the first-stage heat exchanger 21 and the second-stage heat exchanger 22 in series. The heat recovery device is an inclined structure with an angle of 1° to 5° between the center line and the horizontal plane. It includes the first Stage tube box 201, first stage tube pass outlet 202, outer tube sheet 203, first stage effusion chamber, inner tube sheet 205, second stage effusion chamber, shell side inlet 206, cylinder body 207, first stage replacement Heat pipe 208, shell-side outlet 209, second-stage tube-side outlet 210, second-stage tube box 211, split-pass partition 212, second-stage tube-side inlet 213, second-stage liquid effusion ...

Embodiment 2

[0041] In the intensive and energy-saving sulfur trioxide gas cooling system used in the sulfonation process described in this embodiment, the sulfur trioxide heat recovery device is composed of two separate heat recovery devices. The structure of its heat recovery device is identical with that of embodiment 1. The shell-side inlet of the first-stage heat recovery device is connected with the outlet of the sulfur trioxide conversion tower, and the shell-side outlet of the first-stage heat recovery device is connected with the shell-side outlet of the second-stage heat recovery device. The two tube-side inlets of the two heat recoverers can be connected to the supplementary water pump, at least one of the two tube-side outlets of the first-stage heat recovery device is connected to the steam sub-cylinder, and the first-stage heat recovery unit of the second-stage heat recovery The outlet of the tube pass is connected with the inlet of the second-stage tube pass in the first-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com