Capacitor cathode material and preparation method and application thereof

A cathode material and capacitor technology, which is applied in the field of capacitors, can solve the problems of low breakdown voltage and large leakage current of capacitors, and achieve the effects of improving large leakage current, saving costs, and improving low breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

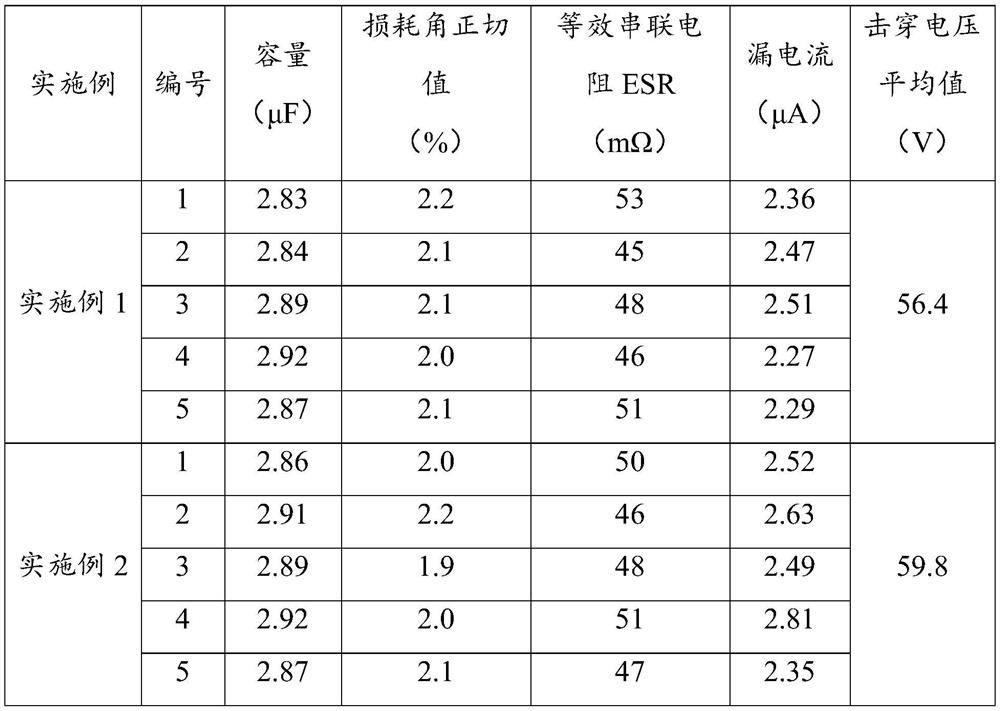

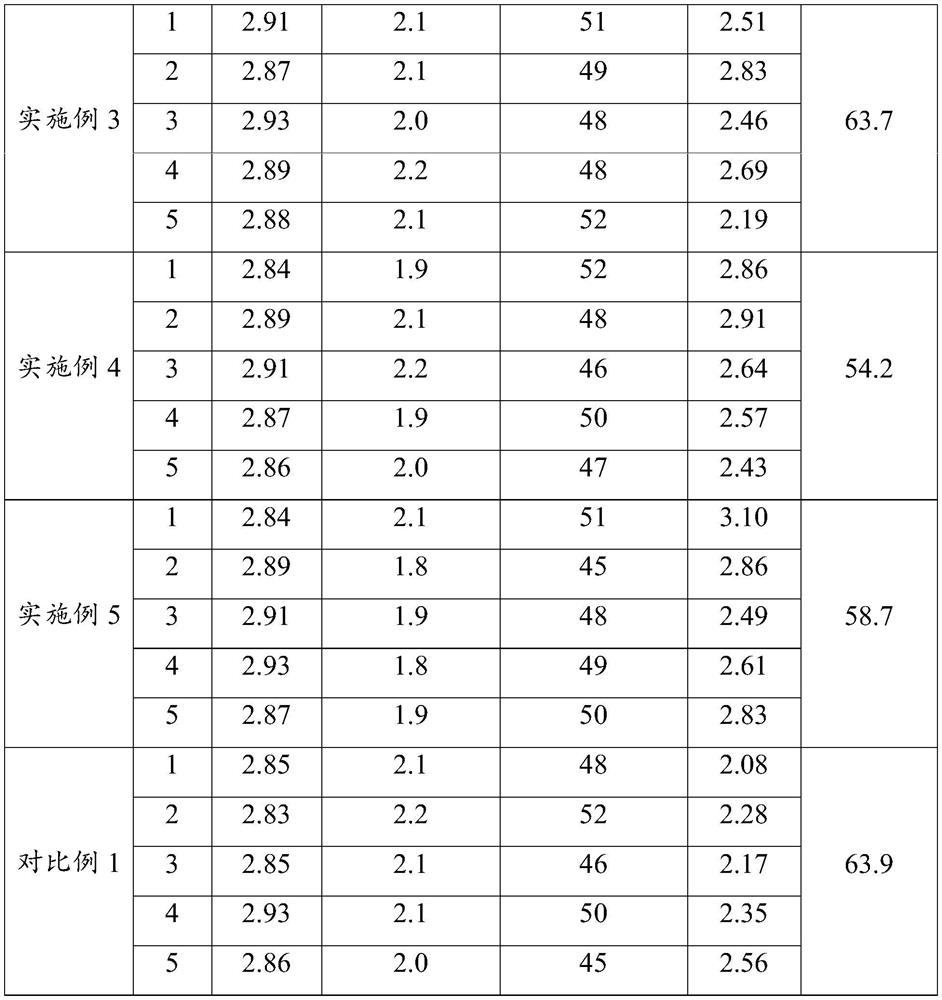

Examples

preparation example Construction

[0036] In the second aspect, the embodiment of the present application provides a method for preparing a capacitor cathode material as provided in the embodiment of the first aspect, including: sequentially forming a surfactant layer, a first conductive polymer layer, a glycerin layer, and a second Two conductive polymer layers.

[0037] It can be understood that, in the embodiments of the present application, the formation methods of the surfactant layer, the first conductive polymer layer, the glycerin layer and the second conductive polymer layer are not limited, for example, by dipping or spin coating etc. formed.

[0038] Considering that the impregnation method is simple to operate and easy to obtain a uniform layer structure, optionally, the layer structures of the surfactant layer, the first conductive polymer layer, the glycerin layer and the second conductive polymer layer of the present application are all in the The corresponding solution is formed by immersion. ...

Embodiment 1

[0058] A method for preparing a capacitor cathode material, comprising:

[0059] S1. Forming a surfactant layer

[0060] Mix 1000g of deionized water and 500g of absolute ethanol evenly, then add 63g of silane coupling agent and stir magnetically for 10min, then pour it into the dipping tank, put it into the aluminum foil to be pretreated, dip for 5min, air dry for 15min, and then put it in the oven for 120 ℃ drying 60min.

[0061] S2. Forming the first conductive polymer layer

[0062] (1) Mix 2500g of absolute ethanol and 80g of 3-methoxythiophene evenly, then magnetically stir for 10min, prepare a monomer solution, then pour it into the dipping tank, put it into the pretreated aluminum foil, dip for 3min, and then Put it into a constant temperature and humidity box with a temperature of 30° C. and a humidity of 60% RH for 10 minutes.

[0063] (2) Mix 2500g of deionized water, 1000g of sodium persulfate and 5g of sodium alkylbenzene sulfonate evenly, then stir for 60 minu...

Embodiment 2

[0071] A method for preparing a capacitor cathode material, comprising:

[0072] S1. Forming a surfactant layer

[0073] Mix 1000g of deionized water and 500g of absolute ethanol evenly, then add 63g of silane coupling agent and stir magnetically for 10min, then pour it into the dipping tank, put it into the aluminum foil to be pretreated, dip for 5min, air dry for 15min, and then put it in the oven for 120 ℃ drying 60min.

[0074] S2. Forming the first conductive polymer layer

[0075] (1) Mix 2500g of absolute ethanol and 80g of 3-methoxythiophene evenly, then magnetically stir for 10min, prepare a monomer solution, then pour it into the dipping tank, put it into the pretreated aluminum foil, dip for 3min, and then Put it into a constant temperature and humidity box with a temperature of 30° C. and a humidity of 60% RH for 10 minutes.

[0076] (2) Mix 2500g of deionized water, 1000g of sodium persulfate and 5g of sodium alkylbenzene sulfonate evenly, then stir for 60 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com