Porphyra haitanensis equipment

A technology of altar laver and equipment, which is applied in the field of altar laver drying, can solve the problems of time-consuming and labor-intensive manual picking, and achieve the effect of saving time and effort, reducing consumption and waste, and taking clean and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

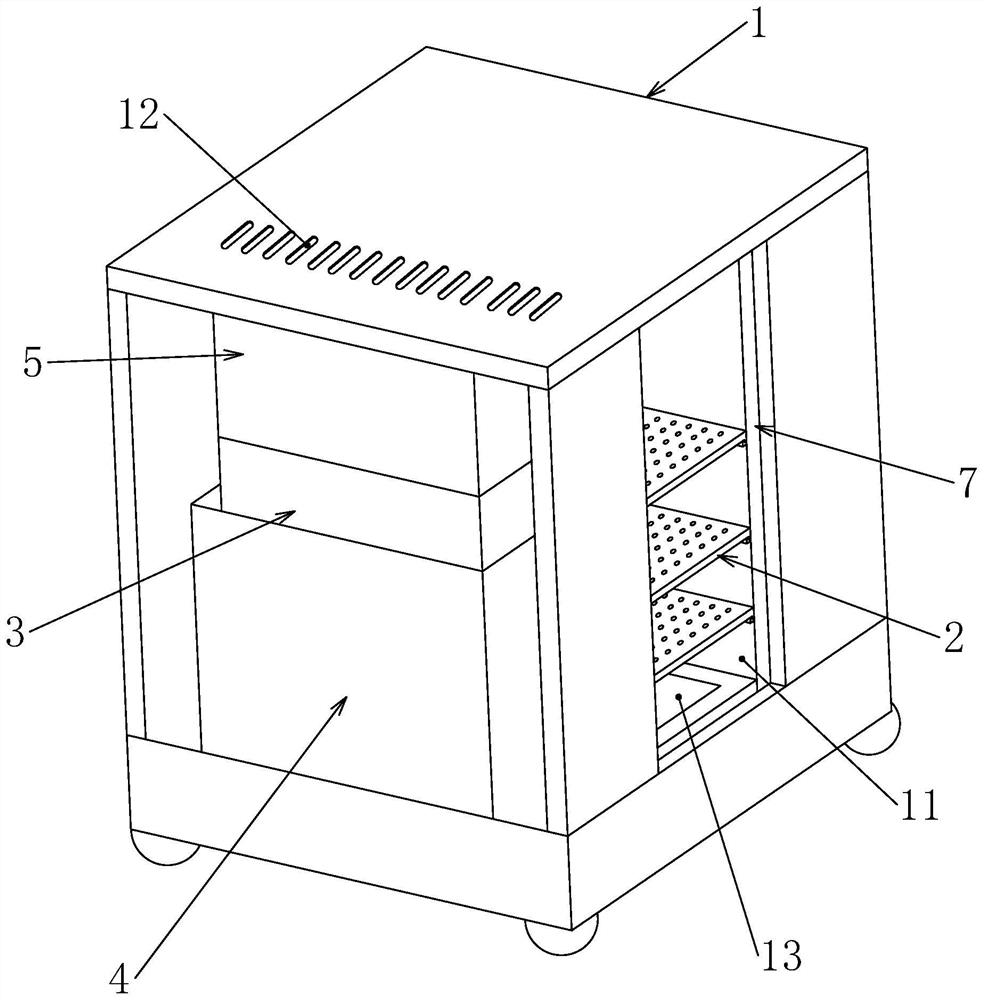

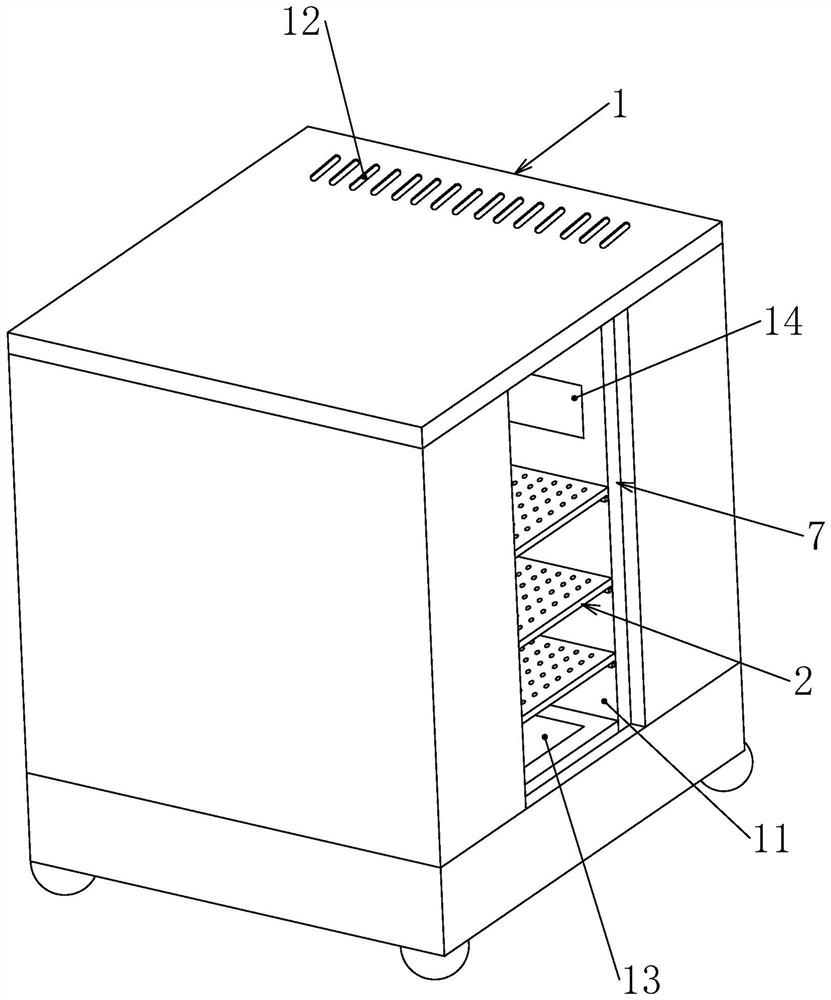

[0053] Embodiment one: if Figure 1-Figure 12 As shown, a altar laver equipment includes: a body 1 and a suction heating device, wherein the body 1 is provided with a channel 11 for placing altar laver, and is provided with an inlet 12 for communicating with the outside world and the interior of the body 1 . Wherein import 12 is made up of several long holes.

[0054] Secondly, in the passage 11, at least one placement tray 2 for placing altar laver is arranged, and the bottom of the passage 11 is provided with an air inlet 13, and the upper side wall of the passage 11 is provided with an air outlet 14.

[0055] And place plate 2 offers the through hole 28 that is convenient to air circulation, and place plate 2 can be provided with scraper 22 movably, and scraper 22 is used for scraping off the altar laver that is placed on place plate 2.

[0056] At the same time, the air suction heating device is arranged in the body 1 and is used to inhale air and output it after heating,...

Embodiment 2

[0077] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference lies in: the structure of the scraper 22, such as Figure 5-Figure 6 As shown, the scraper 22 moves horizontally on the placement tray 2 and a moving part is provided at the bottom of the scraper 22 , while the placement tray 2 is provided with a chute 23 , and the moving part is horizontally slidably arranged in the chute 23 .

[0078] Therefore, in the actual use process, the scraper 22 is scraped by horizontally moving to replace the manual picking, so that the picking is cleaner and saves time and effort. And the scraper 22 plays a guiding role, so that the altar laver is pushed and moved along the scraper 22, and when the placement plate 2 moves in the channel 11 or the altar laver is placed on the placement plate 2, since the scraper 22 is located on the side It can play the role of limiting the altar laver and prevent the altar laver from falling from the placement plate 2 .

[0...

Embodiment 3

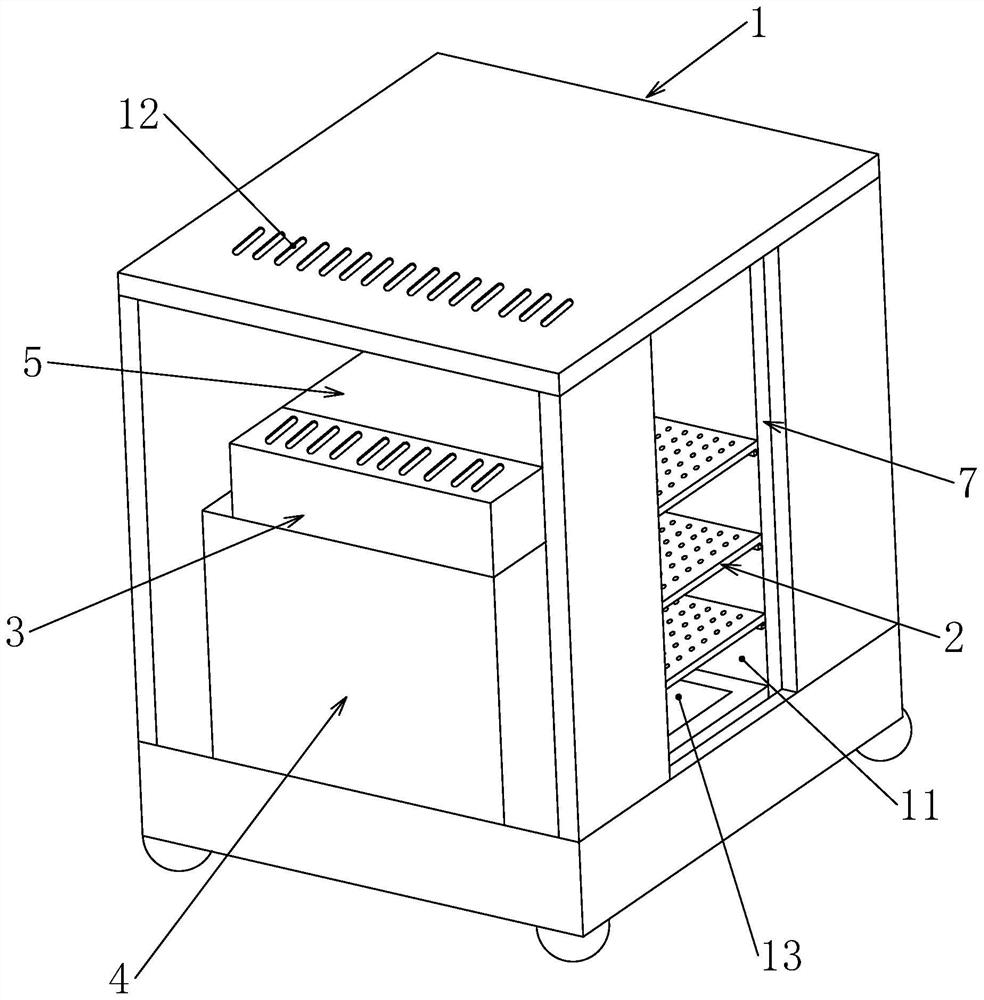

[0080] Embodiment three: this embodiment is basically the same as embodiment one, the difference is that the structure of the air duct one 5, such as Figure 7 As shown, firstly, the first air channel 5 extends upwards and communicates with the inlet 12, and the top opening of the air channel one 5 is smaller than the opening of the inlet 12.

[0081] Therefore, in actual use, the outside space can enter the blower fan 3 quickly and intensively along the air duct one 5 instead of being scattered randomly. And the top opening of the air duct 5 is smaller than the opening of the inlet 12, so that part of the air is used for cooling the internal components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com