Hydrophobic magnetic porous material and preparation and application thereof

A porous material and magnetic technology, used in the preparation and application of functional materials, can solve problems such as inability to work, adsorption efficiency dependent on light intensity, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, expression and purification of recombinant ferritin PfFn

[0047] In this example, the recombinant ferritin PfFn derived from Pyrococcus furiosus was used to prepare magnetic ferritin. In other embodiments, ferritin from other sources can also be used to prepare magnetic ferritin, such as ferritin from human, Pyrococcus furiosus, Pyrococcusyayanosii CH1, or Archaeoglobusfulgidus.

[0048] In GenBank, according to the cDNA sequence of ferritin PfFn of thermophilic bacteria (Pyrococcus furiosus), the accession number is 1468595, the sequence is modified by codon preference and expressed in the E. coli expression system. The modified gene sequence is shown as SEQ ID No.1 Shown; the gene sequence was linked into the pET22b plasmid, and named pET22b-PfFn.

[0049] The pET22b-PfFn vector was transformed into Escherichia coli BL21(DE3) strain competent cells. Positive clones were screened on solid LB medium containing ampicillin, that is, the transformed strain...

Embodiment 2

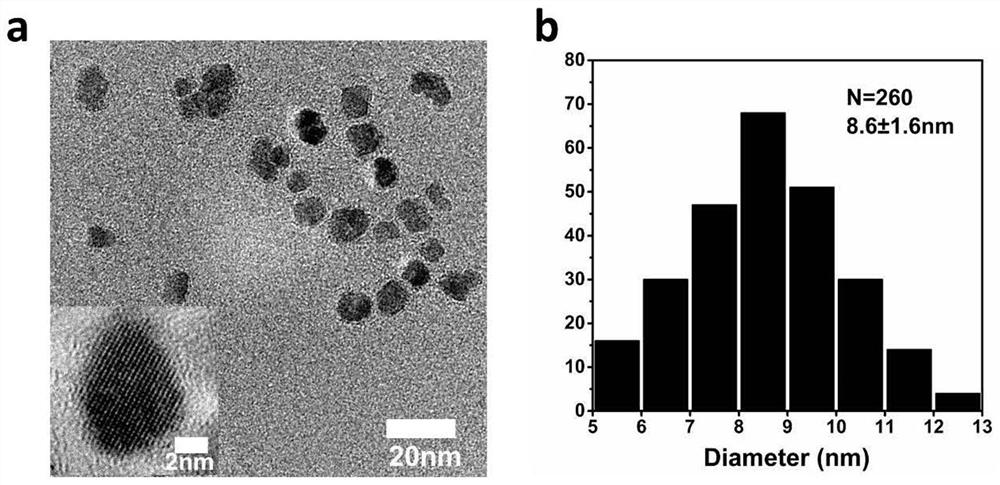

[0050] Embodiment 2, PfFfn mineralization synthesis magnetic ferritin MPfFn

[0051] The recombinant thermophilic ferritin PfFn purified in Example 1 was desalted in 0.1M sodium chloride solution, diluted to 1 mg / mL after the concentration was measured, and 40 mL was put into a reaction container for degassing for 5 minutes for later use. Prepare 0.1M NaOH, 50mM ferrous ammonium sulfate, and 16.67mM hydrogen peroxide solution in the anaerobic box with deaerated water, set the temperature of the connected reaction device to 90°C, adjust the pH to 8.5, start the reaction, and control the reaction rate to Each ferritin shell enters 80 ferrous ions per minute, ensuring that the molar ratio of the number of ferrous ions added to the reaction system and the oxidation of hydrogen peroxide is 3:1, so that the theoretically synthesized magnetic particles are Fe 3 o 4 When the volume of ferrous ammonium sulfate added reaches the stoichiometric amount of 15,000 iron atoms in each ferrit...

Embodiment 3

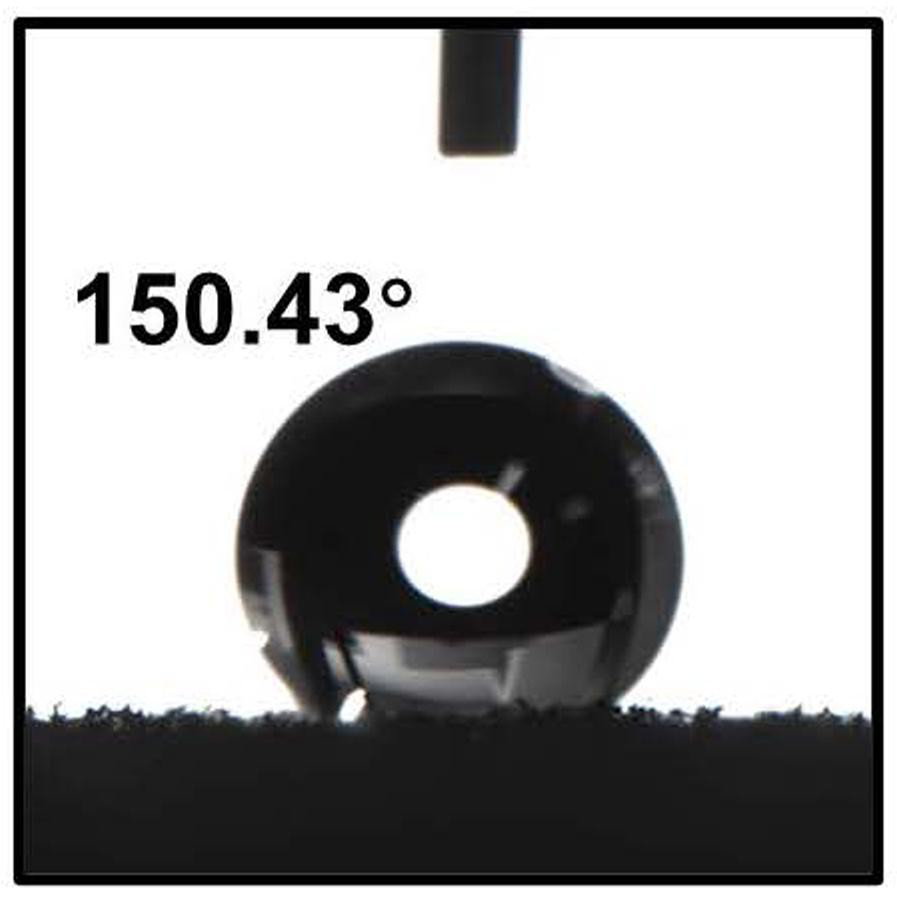

[0053] Embodiment 3, the preparation of hydrophobic magnetic sponge

[0054] In this example, a hydrophobic magnetic porous material was prepared by using polyurethane sponge as a porous matrix and the magnetic ferritin obtained above.

[0055] Take a polyurethane sponge (PUS), cut it into cubes with a side length of 3 cm, put the cut sponge into 50 mL of absolute ethanol for 20 min, and take it out to dry at 60°C for later use. Take 100mL of the magnetic ferritin MPfFn solution in the above-mentioned Example 2, add an equal volume of absolute ethanol, stir evenly, adjust the pH of the solution to 9.2, add 2g / L dopamine hydrochloride to the solution, and stir fully to make it completely Dissolve, completely soak the above polyurethane sponge in the prepared solution, shake it at room temperature for 6 hours, take it out, wash both sides with deionized water, and dry at 60°C to obtain MPfFn-modified magnetic sponge. After the shaking, it can be clearly seen that the solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com