Steel pipe stamping forming device

A technology of stamping and forming, steel pipe, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of long process, inconvenient steel pipe processing and rust prevention, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

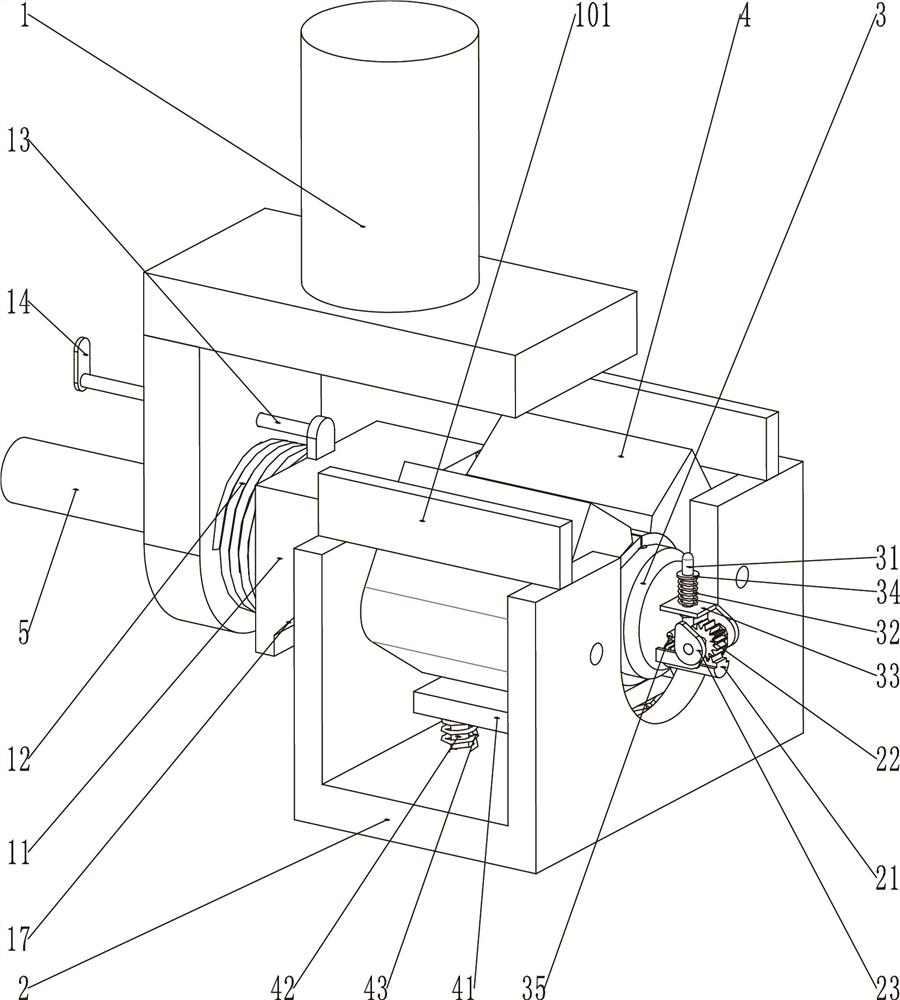

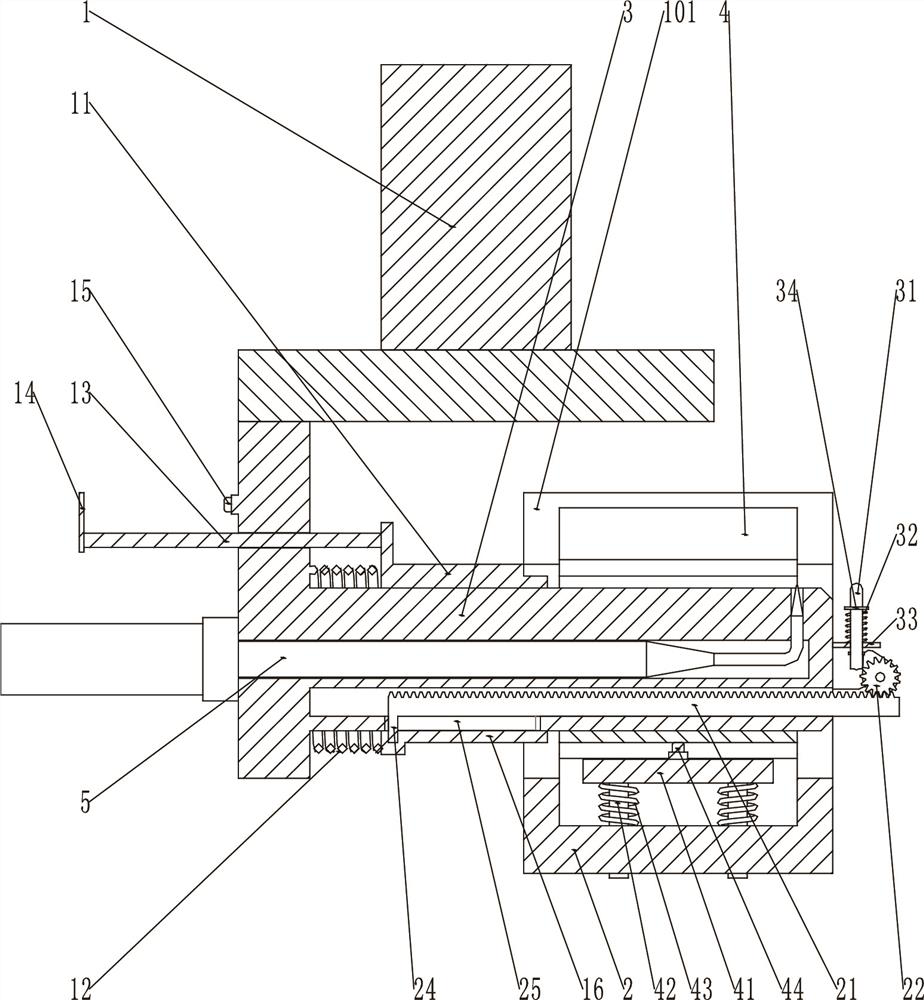

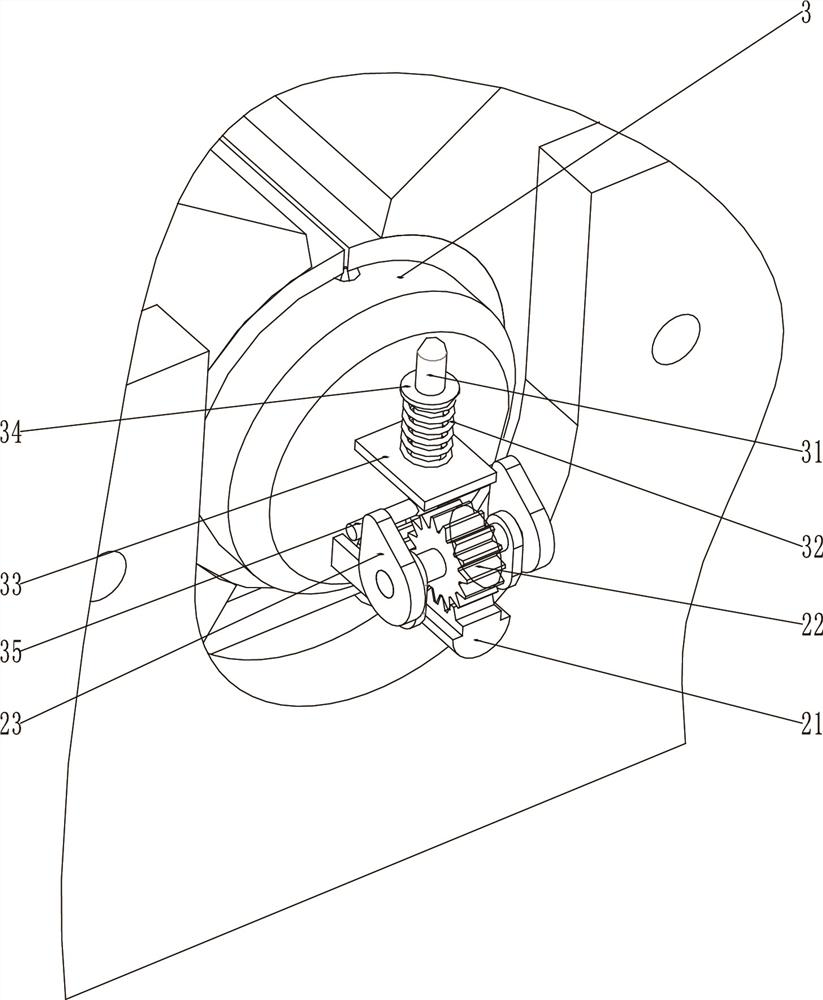

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments: see Figure 1-Figure 7 , a steel pipe stamping and forming device, including a punch 1 and a lower die 2, the lower die 2 is fixed on a frame, and the punch 1 can slide up and down on the frame through electrical control to be placed on the lower die 2 of blank sheet forming.

[0022] The punch 1 is provided with a forming rod 3, the forming rod 3 is a cylindrical shape that matches the inner diameter of the required steel pipe, the forming rod 3 is laterally fixed on the punch 1, and the lower die 2 is symmetrically arranged. There is a forming die 4 matched with the forming rod 3. The forming die 4 is a synthetic die that is rotationally symmetrically arranged on the lower die 2, that is, the symmetrically arranged forming die 4 are merged to form a cavity that matches the outer diameter of the steel pipe. , baffles 101 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com