High-strength composite single corrugated board and preparation method thereof

A technology for compounding single corrugated and corrugated cardboard, applied in the field of packaging materials, can solve the problems of high material consumption of corrugated boxes, restricting industrial applications, weak adhesion, etc., improving adhesion strength and pressure resistance, and reducing production costs. , Improve the effect of waterproof and moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

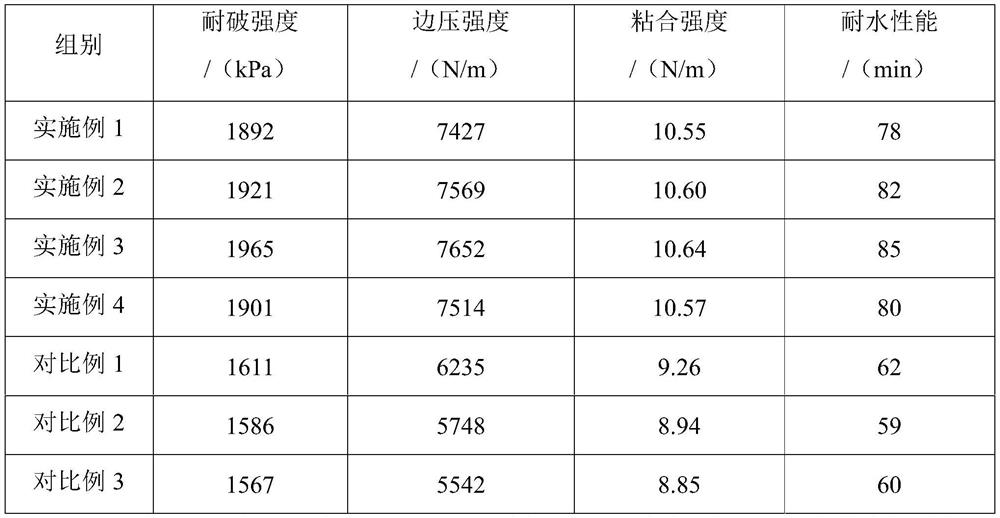

Examples

Embodiment 1

[0028] A method for preparing a high-strength composite single-corrugated board, the high-strength composite single-corrugated board includes a composite single-corrugated paper core and a face paper and an inner paper bonded and fixed to the upper and lower surfaces of the composite single-corrugated paper core, comprising the following steps:

[0029] S1. Preparation of corrugated paper core: Preheat the corrugated base paper with a preheater at a temperature of 103°C, and then emboss the heated corrugated base paper with a corrugating roller to obtain a corrugated corrugated paper core;

[0030] S2. Preparation of composite single corrugated paper core: bonding two corrugated paper cores obtained in step S1 with an adhesive to obtain a composite single corrugated paper core;

[0031] S3. Preheating treatment of the face paper and the inner paper: the face paper and the inner paper are preheated respectively, and the preheating temperature is 103°C;

[0032] S4. Compounding ...

Embodiment 2

[0045] A method for preparing a high-strength composite single-corrugated board, the high-strength composite single-corrugated board includes a composite single-corrugated paper core and a face paper and an inner paper bonded and fixed to the upper and lower surfaces of the composite single-corrugated paper core, comprising the following steps:

[0046] S1. Preparation of corrugated paper core: Preheat the corrugated base paper with a preheater at a temperature of 105°C, and then emboss the heated corrugated base paper with a corrugating roller to obtain a corrugated corrugated paper core;

[0047] S2. Preparation of composite single corrugated paper core: bonding two corrugated paper cores obtained in step S1 with an adhesive to obtain a composite single corrugated paper core;

[0048] S3. Preheating treatment of the face paper and the inner paper: the face paper and the inner paper are preheated respectively, and the preheating temperature is 105°C;

[0049] S4. Compounding ...

Embodiment 3

[0062] A method for preparing a high-strength composite single-corrugated board, the high-strength composite single-corrugated board includes a composite single-corrugated paper core and a face paper and an inner paper bonded and fixed to the upper and lower surfaces of the composite single-corrugated paper core, comprising the following steps:

[0063] S1. Preparation of corrugated paper core: Preheat the corrugated base paper with a preheater at a temperature of 105°C, and then emboss the heated corrugated base paper with a corrugating roller to obtain a corrugated corrugated paper core;

[0064] S2. Preparation of composite single corrugated paper core: bonding two corrugated paper cores obtained in step S1 with an adhesive to obtain a composite single corrugated paper core;

[0065] S3. Preheating treatment of the face paper and the inner paper: the face paper and the inner paper are preheated respectively, and the preheating temperature is 105°C;

[0066] S4. Compounding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com