Method for preparing high-purity sebacic acid

A technology for producing sebacic acid monosodium salt and sebacic acid, which is applied in the field of high-purity sebacic acid preparation, and can solve the problems of ineffective reduction of sebacic acid monoacid content and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

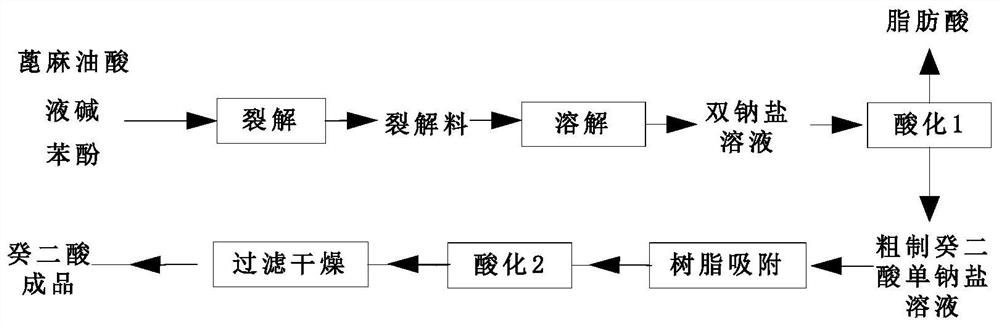

Method used

Image

Examples

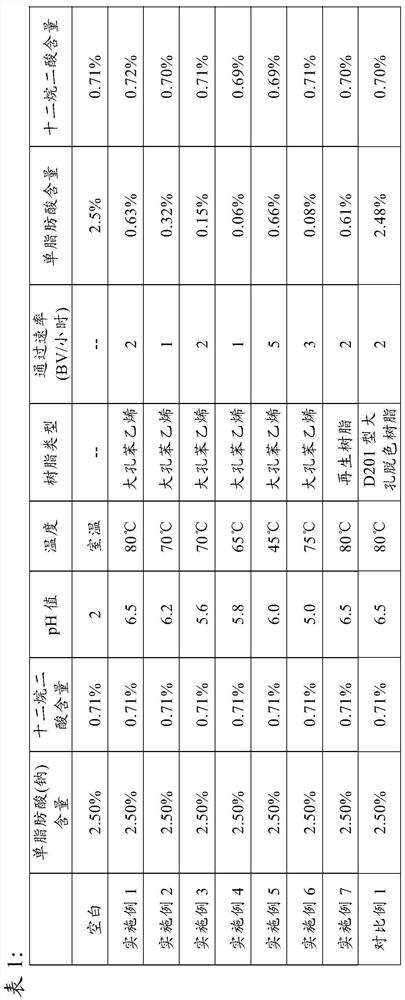

Embodiment 1

[0084] A thicker sebacate sodium salt solution was taken 1000 ml, with a single fatty acid (sodium) content of 2.50%, and 0.71% of dodecylic acid content. The pH was adjusted to 6.5, and the control temperature was 80 ° C, and the resin column was filled with a resin column in the resin column. The single sodium salt solution passes through the resin column at a rate of 2 BV / hour. The sodium salt solution after adsorption was collected, and the sebacalic acid finished was obtained by the same process as blank experiment, and the total content of single fatty acid was 0.63%, and the dodecyclic acid content was 0.72%.

Embodiment 2

[0086]The crude sebacate is 500 ml of the crude sebacate, wherein the single fatty acid (sodium) content is 2.50% relative to the sebacalic acid content, and the pH is adjusted to 6.2, the control temperature is 70 ° C, and the resin is adsorbed by the porestone styrene. The column, the resin column is filled with 10 g of the resin. The single sodium salt solution passes through the rate of 1 BV / hr. After collecting the adsorption, a sodium salt solution was collected, and the sebacalic acid finished product was obtained by the same process as blank experiment, and the total content of single fatty acid was 0.32%, and the dodecyclic acid content was 0.70%.

Embodiment 3

[0088] 300 ml of a thickened sodium sodium salt solution, wherein the single fatty acid (sodium) content was 2.50% relative to the sebacalic acid content, and the pH was adjusted to 5.6, and the control temperature was 70 ° C, and the resin column was adsorbed by the sputum styrene. 10G resin is filled in the resin column. The single sodium salt solution passes through the resin column at a rate of 2 BV / hour. The sodium salt solution after adsorption was collected, and the sebacaric acid finished was obtained by the same process as blank experiment, and the total content of single fatty acid was 0.15%, and the dodecyllate was 0.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com