Continuous engraving device for cement packaging bag

A technology for packaging bags and cement, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of labor-intensive and low-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

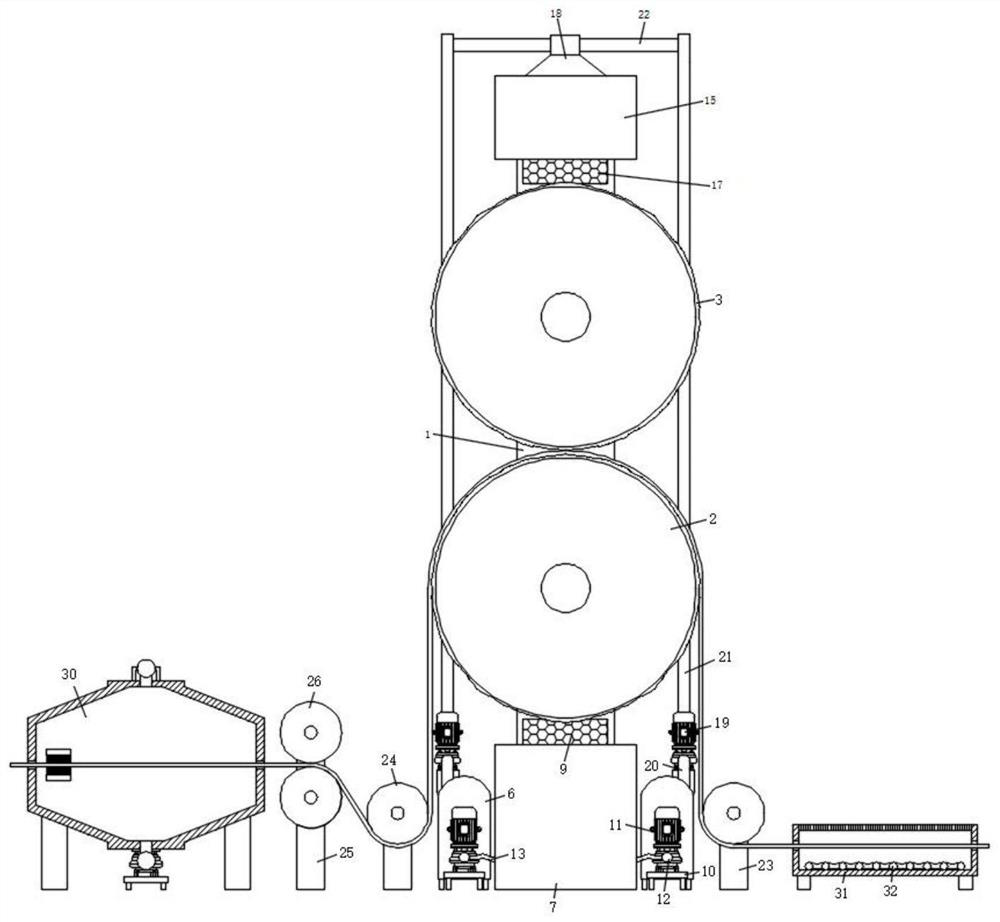

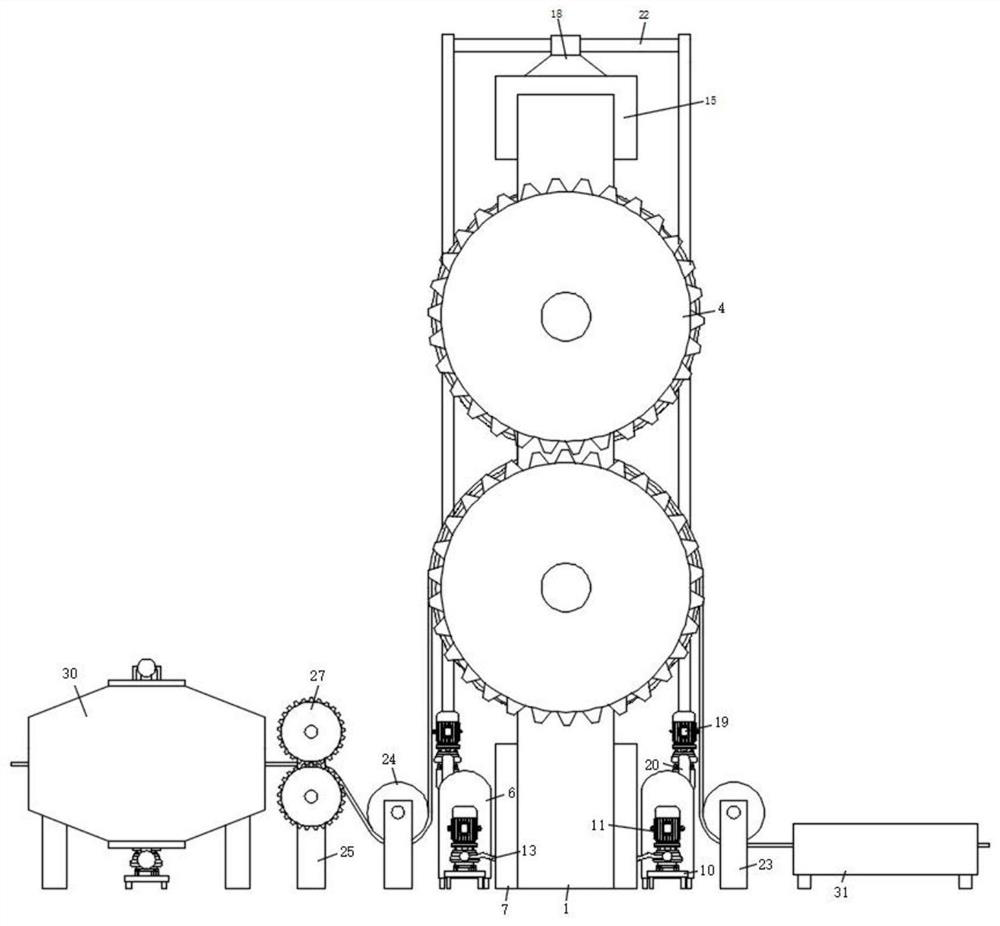

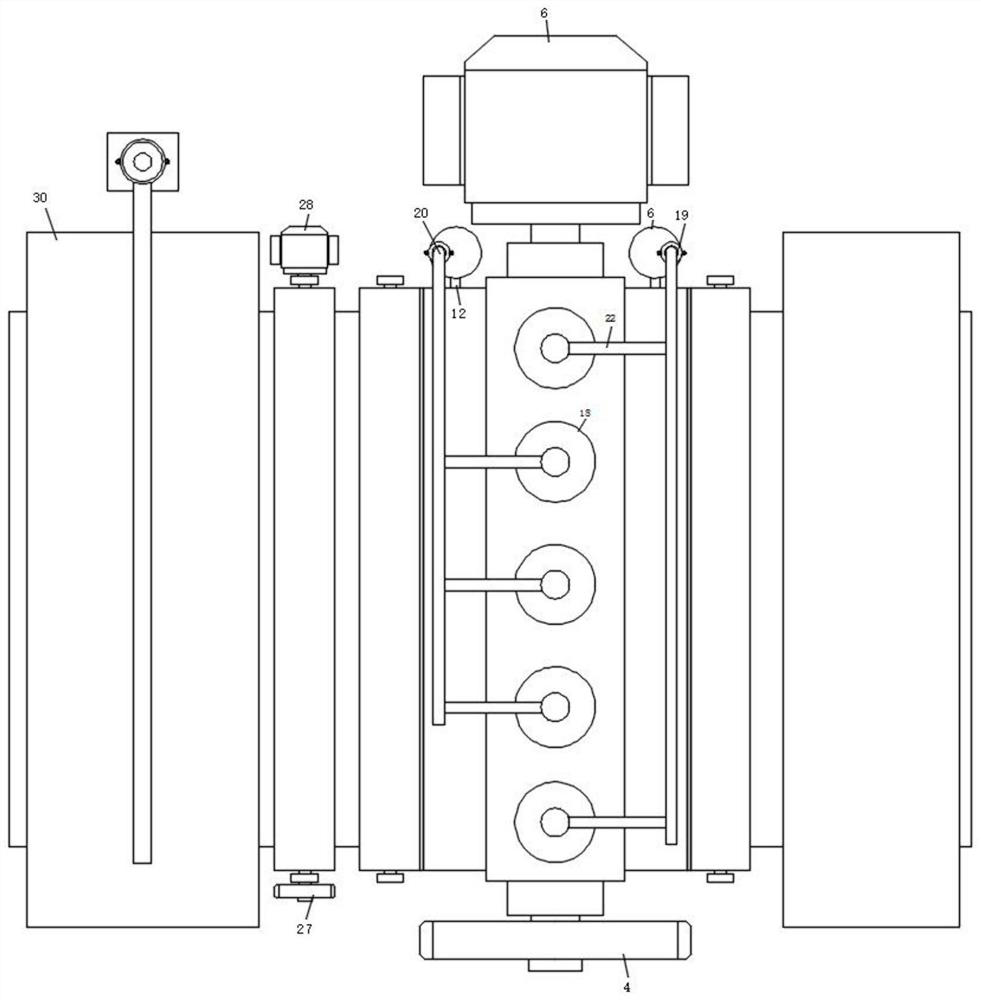

[0033] refer to Figure 1-6, a continuous engraving device for cement packaging bags, including a support base 1, two support bases 1 are arranged and symmetrically distributed on the rear side of the working face, the upper and lower ends of the two support bases 1 are rotatably connected with an engraving roller 2, and the engraving roller 2 The printing plate 3 is engraved on the outer wall, and two engraving rollers 2 are used to rotate to realize the continuous engraving operation on both sides of the cement bag. The work efficiency is high and the printing position is accurate, so as to ensure the high-efficiency printing of the cement bag and the quality of the cement bag printing. The front ends of the two engraving rollers 2 pass through the support base 1 and are connected in rotation by a gear set-4. The rear side of the support base 1 is also provided with a fixed base. The top surface of the fixed base is fixed with a servo motor-5 by screws. The output end of mot...

Embodiment 2

[0036] Such as figure 1 , 2 As shown in and 6, this embodiment is basically the same as Embodiment 1. Preferably, the dust removal mechanism 30 includes a dust removal vessel 301, and the front and rear inner walls of the dust removal vessel 301 are fixed with installation strips 302, and two installation strips 302 of the same group are close to one end Both are fixed with brushes 303, and the outer bottom surface and top surface of the dust-cleaning dish 301 are fixed with the main pipe 304 for absorbing dust. An installation platform 306 is provided, and the top surface of the installation platform 306 is fixedly connected with an air pump 307 by screws.

[0037] There are multiple installation strips 302 and are distributed in groups on the front and rear side inner walls of the ash cleaning vessel 301, and multiple sets of installation strips 302 are arranged in a row, each group of installation strips 302 is provided with two, and the ash suction pipe 305 is provided wi...

Embodiment 3

[0040] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the drying mechanism includes a drying box 31, a heating pipe 32 is fixed on the inner bottom surface of the drying box 31, and an exhaust gas is provided through the top surface of the drying box 31. Holes, exhaust holes are provided with a plurality and are distributed on the top surface of the drying box 31 in a matrix.

[0041] In this embodiment, after the cement bag is printed, it is input into the drying box 31 in time. At this time, under the action of the heating pipe 32, the timely drying of the cement bag printing ink is realized, which can well avoid ink adhesion and loss during cement bag printing. The occurrence of this phenomenon provides a certain guarantee for the clear and high-quality printing of cement bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com