Combined-edge indexable machining forming tool

An additive and indexing technology, applied to milling cutters, manufacturing tools, metal processing equipment, etc., can solve problems such as easy chipping and frequent tool changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

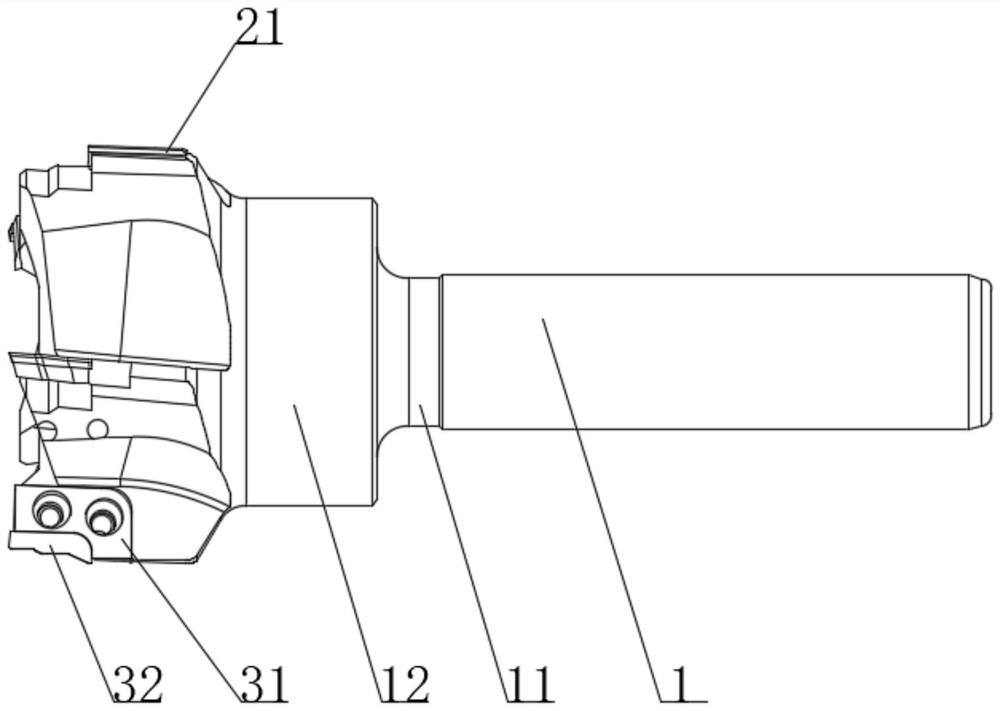

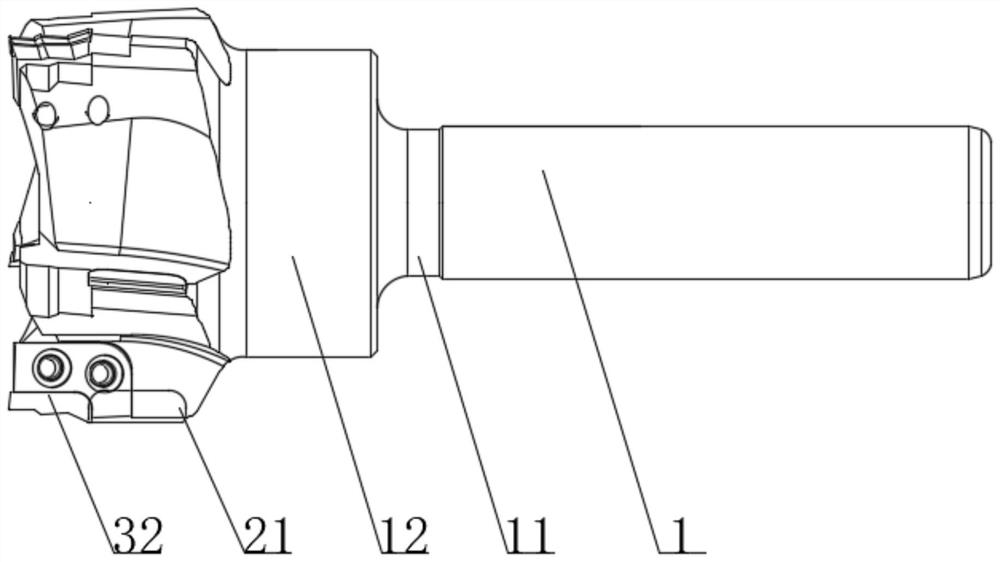

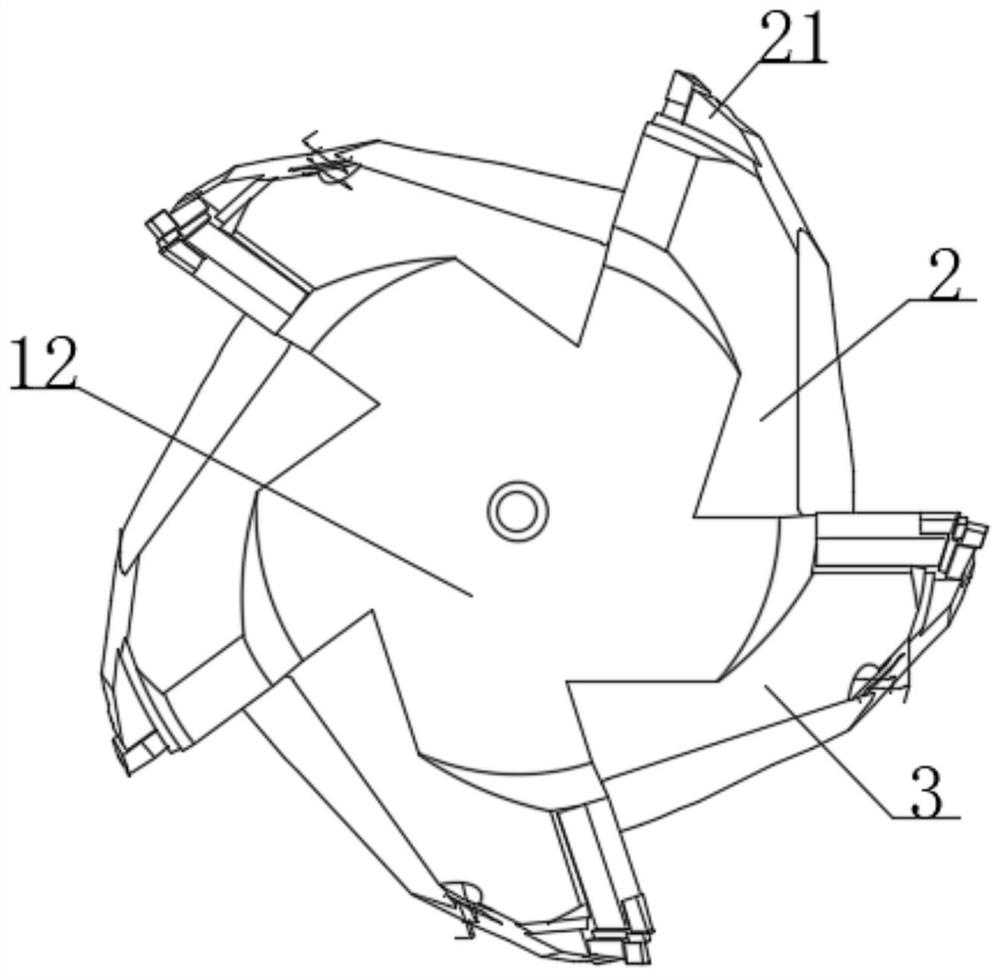

[0029] see Figure 1-6 , the present invention provides a technical solution: a class of combined blade indexable machine addition type cutting tools, including a fixed seat 1, a first base body 2 and a second base body 3, one end of the fixed seat 1 is fixedly connected with a connecting seat 11, and the connecting seat 11 One end is fixedly connected with a mounting seat 12, one side of the periphery of the mounting seat 12 is a cylindrical structure, and the other side of the periphery of the mounting seat 12 is a five-blade paddle structure, and the multi-tooth cutting effect can be effectively realized through the five-blade paddle structure. The connection between 11 and mounting base 12 is high-frequency welding, and the welding piece is silver-copper welding piece, thereby improving the stability of the connection and improving the structural strength;

[0030] Both sides of the periphery of the mounting seat 12 are fixedly connected with a first base body 2 near one e...

Embodiment 2

[0043] see Figure 1-6 , the present invention provides a technical solution: a class of combined edge indexable machine-additional cutting tools, including a fixed seat 1, a first base body 2 and a second base body 3, the fixed seat 1 has a cylindrical structure, and the fixed seat 1 can effectively It is convenient to clamp and fix the machine-added cutting tool. One end of the fixed seat 1 is fixedly connected with the connecting seat 11. The connecting seat 11 has a circular platform structure. Through the connecting seat 11, it is convenient to guide the transmission force. High-frequency welding is used between them. One end of the connecting seat 11 is fixedly connected with the mounting seat 12. One side of the periphery of the mounting seat 12 has a cylindrical structure, and the other side of the periphery of the mounting seat 12 has a five-blade paddle structure. The five-blade paddle structure can Effectively realize the multi-tooth cutting effect, high-frequency w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com