Method for recycling unreacted chlorine gas in chloroethylene carbonate synthesis

A technology of unreacted chloroethylene carbonate, which is applied in the field of recovery and reuse of unreacted chlorine gas in the synthesis of chloroethylene carbonate, and can solve problems such as unsustainable normal production, increased cost, and increased impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

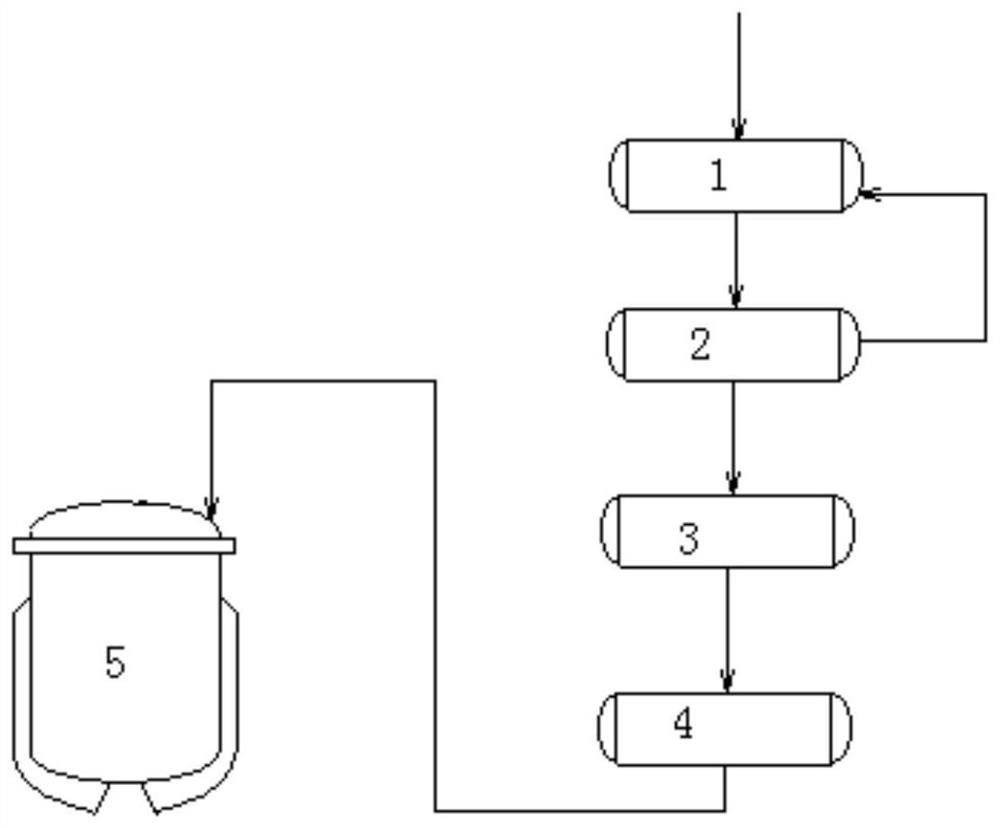

[0014] A device for recovering and reusing unreacted chlorine gas in the synthesis of chloroethylene carbonate, comprising a three-stage water spray device 1, a water eliminator 2, a 98% sulfuric acid drying tower 3, a mist eliminator 4 and chlorine chemical reaction kettle 5, and the water eliminator 2 is connected with the three-stage water spraying device 1 through a pipeline.

Embodiment 2

[0016] On the basis of embodiment 1, the steps are as follows: (1) the mixed gas produced in the synthesis of chloroethylene carbonate is discharged into a three-stage water spray device to absorb hydrogen chloride gas to obtain 30% hydrochloric acid; (2) through the steps ( 1) The treated mixed gas enters the water eliminator, and the acid water obtained is discharged into the three-stage water spray device through the pipeline; (3) The mixed gas treated in step (2) enters the 98% sulfuric acid drying tower; (4) After The mixed gas treated in step (3) enters the demister; (5) the mixed gas treated in step (4) enters the chlorination reactor;

[0017] In the step (1), the temperature in the three-stage water spraying device is not higher than 30°C;

[0018] The temperature in the drying tower in the step (3) is not higher than 30°C.

Embodiment 3

[0020] The temperature in the step (1) in the three-stage water spraying device is 20°C;

[0021] The temperature in the drying tower in the step (3) is 10° C.; the others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com