A component lead forming device and method of using the same

A component and lead technology, applied in the field of component lead forming devices, can solve the problems that standard forming cannot meet design requirements, poor forming quality stability, affecting welding reliability, etc., and achieve high bending forming efficiency and dimensional stability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

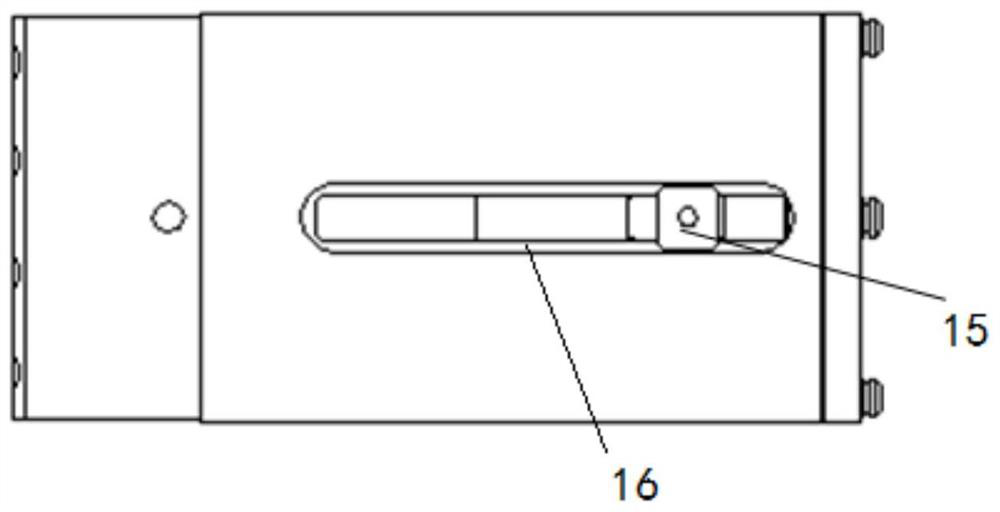

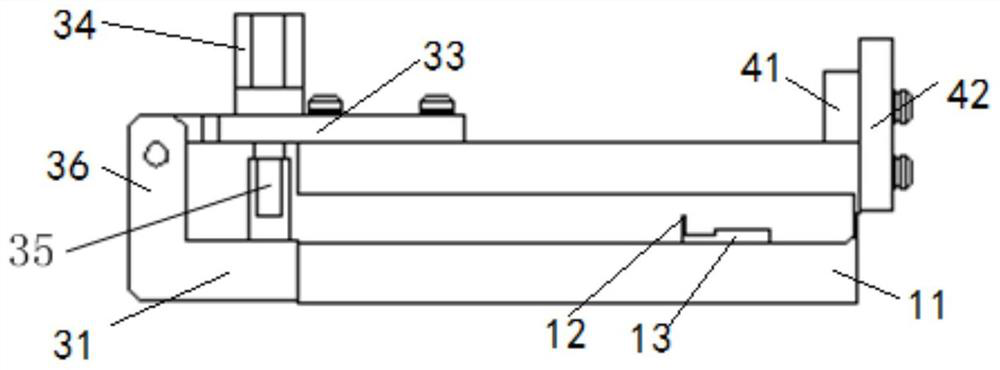

[0041] The following will combine Figure 1 to Figure 10 A component lead forming device provided by the present invention is described in detail. This embodiment is implemented on the premise of the technical solution of the present invention, and a detailed implementation manner and a specific operation process are given, but the protection of the present invention is given. The scope is not limited to the following embodiments, and those skilled in the art can make modifications and improvements within the scope of not changing the spirit and content of the present invention.

[0042] Please refer to Figure 1 to Figure 10 , a component lead forming device, the component 5 includes a component body 51 and a lead 52; the forming device includes:

[0043]The body clamping module 1 includes a lower pressing plate 11 and an adjusting plate 13, the adjusting plate 13 is movably arranged on the upper end surface of the lower pressing plate 11, and the adjusting plate 13 can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com