Wellhead excitation type detection method for defects of outer coating of casing of shallow well in oil field

A detection method and outer coating technology, applied in wellbore/well components, measurement, earthwork drilling, etc., can solve the problem of not reflecting the quality of the coating, and achieve the effect of reliable principle and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

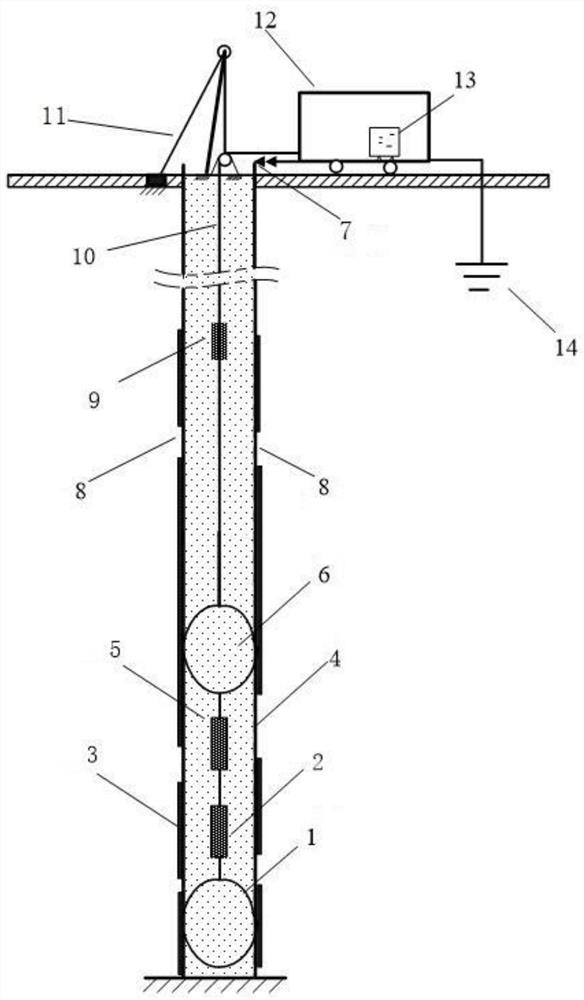

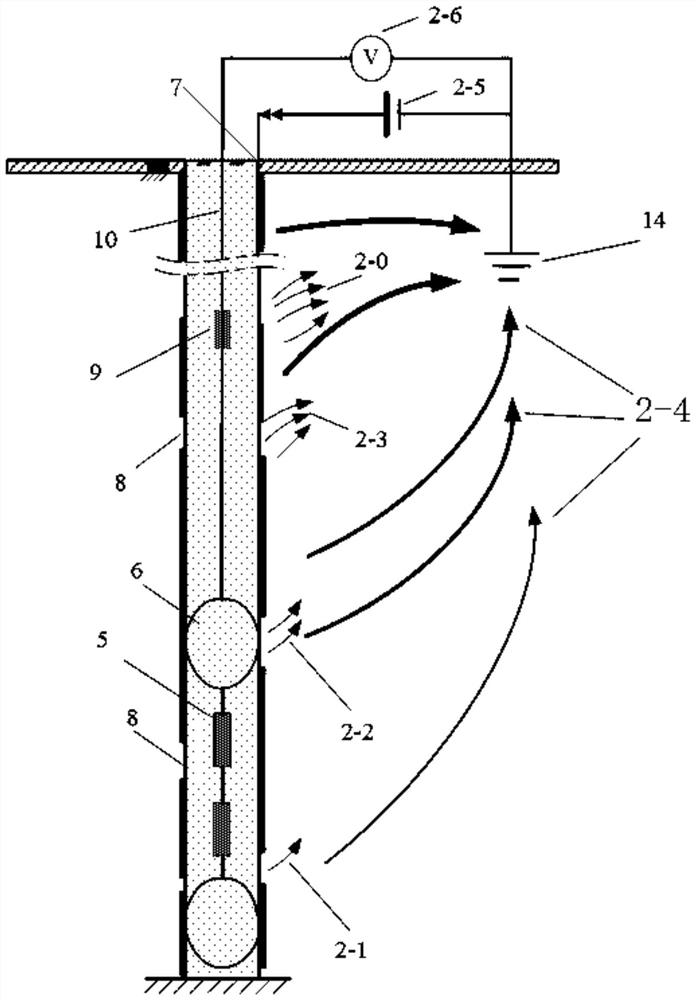

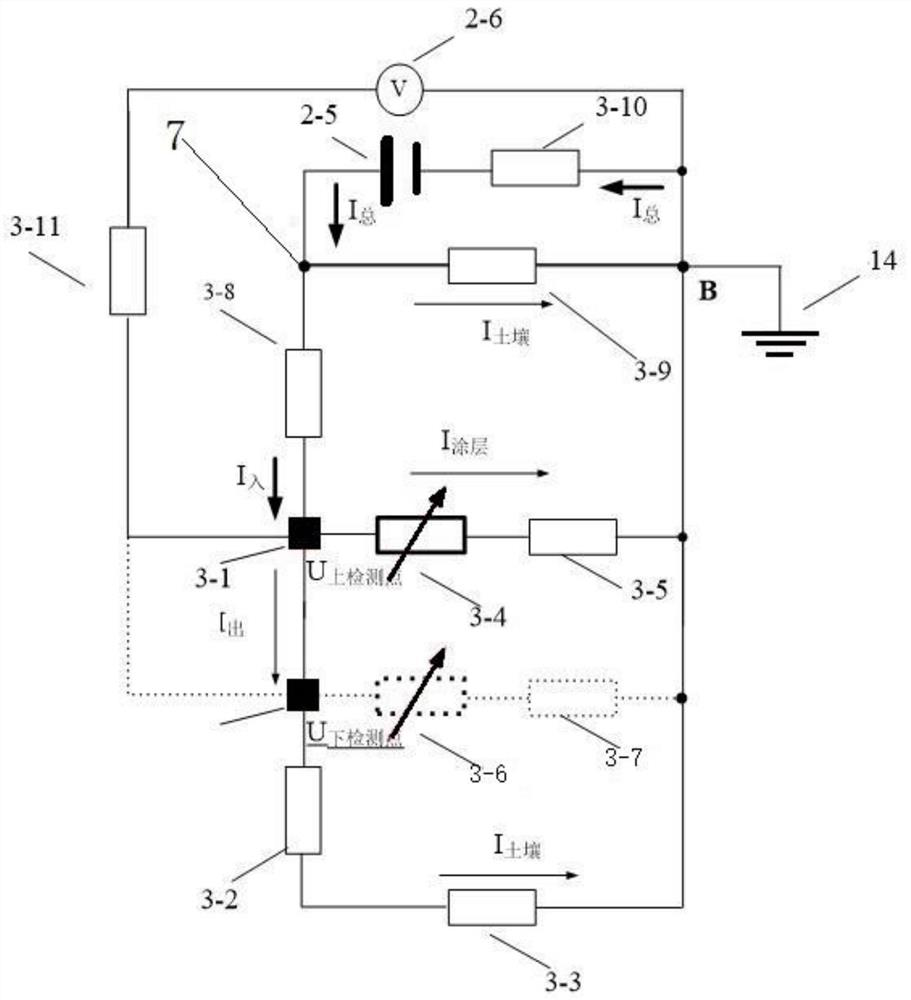

[0029] In order to overcome the existing problems that cannot reflect the quality of the coating, the present invention provides such as Figure 1-3 Shown is a wellhead excitation detection method for casing outer coating defects in shallow wells in the oil field. The invention uses measuring electrodes to measure the difference in potential change caused by the quality difference of coating defects to achieve the purpose of reflecting the quality of the coating. .

[0030] A wellhead excitation type detection method for casing outer coating defects in shallow wells in an oil field, comprising the following steps:

[0031] Step 1: In the wells with intact outer coating, detect the outer coating of the casing, collect the well depth, measure the electrode potential data, and draw the well depth-intact coating potential curve obtained with the casing coating intact. This potential data is regarded as the casing outer coating intact standard data in the case of

[0032] Step 2:...

Embodiment 2

[0037] Based on the basis of Example 1, in this embodiment, preferably, in the step 1, the detection method of the outer coating is: after the well with the outer coating is intact, the well is cleaned, and the electrolyte is injected, the The ground loop electrode is buried on the side of the ground away from the wellhead, and the positive pole of the power supply is connected to the wellhead casing, and then the instrument string is lowered, and the instrument is adjusted to a normal state while going down to the bottom of the well; the detection program is started during the lifting of the instrument string, and the normal The electrodes provide constant voltage signals, and the instrument string collects well depth and measures electrode potential data.

[0038] Preferably, the instrument string includes a bridle 9 connected sequentially from top to bottom, a detection electrode 6, a magnetic locator 5, a weighting rod 2 and a centralizer 1; the bridle 9 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com