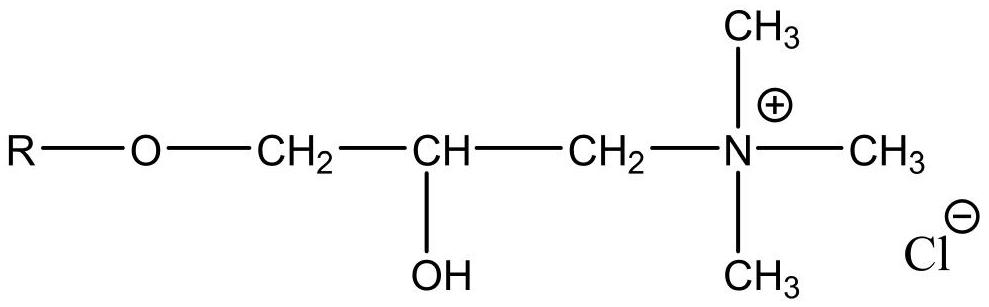

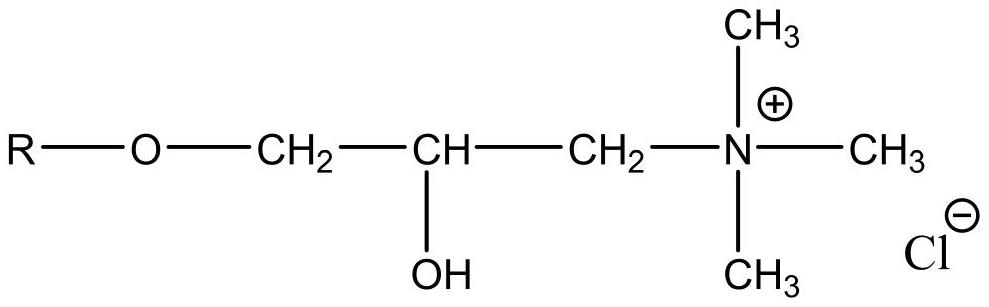

Quaternized polyether reverse demulsifier and preparation method thereof

A technology of inverse demulsifier and quaternized polyether, which is applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of high cost, easy stratification, long reaction time, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] First, take 81.8g of polyether and 2.5g of epichlorohydrin, add them to a four-neck flask, mix well, and heat up to 60°C; at this time, weigh 4.84g of 33% trimethylamine solution and 10g of distilled water, and mix the two Then add it into the buret, start dropwise at 60°C, after the dropwise addition time is 1h, heat up to 75°C, react for 3h; cool to 40°C, add 70g of 75% ethanol solution to obtain a quaternary solution with a solid content of 50%. Ammonized polyether inverse demulsifier a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com