Power-off control method based on full-power electric-electric hybrid fuel cell vehicle

A fuel cell, full-power technology, applied in the direction of electric vehicles, vehicle components, electrical devices, etc., can solve the problems of lack of fuel cell life and safety considerations, inapplicability, and inability to ensure that the high voltage of the whole vehicle does not switch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

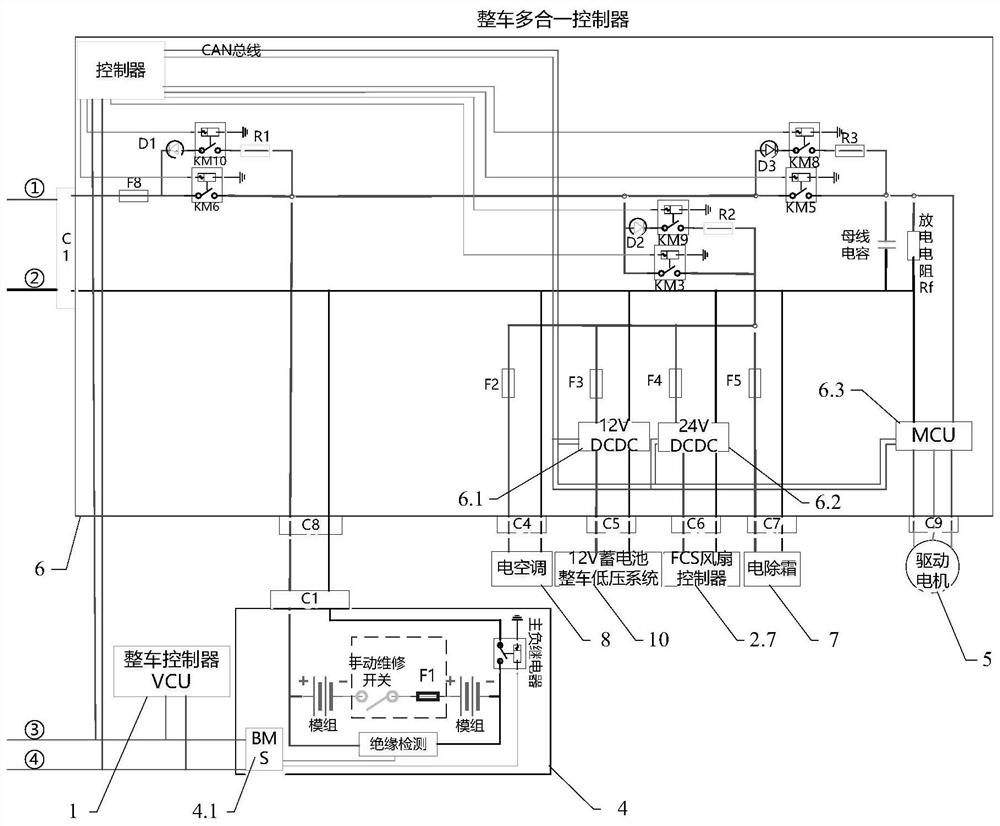

[0054] Such as Figure 1~3 As shown, the full-power electric-electric hybrid fuel cell vehicle designed in this embodiment includes a vehicle controller VCU 1, a fuel-electricity system FCS 2, a hydrogen storage system HMS 3, a power battery system 4, a drive motor 5, and a vehicle multi-combination system. A controller 6, defrosting and defogging PTC (electric defrosting) 7, electric air conditioner ACS 8, 12V low-voltage battery 10 (vehicle low-voltage system).

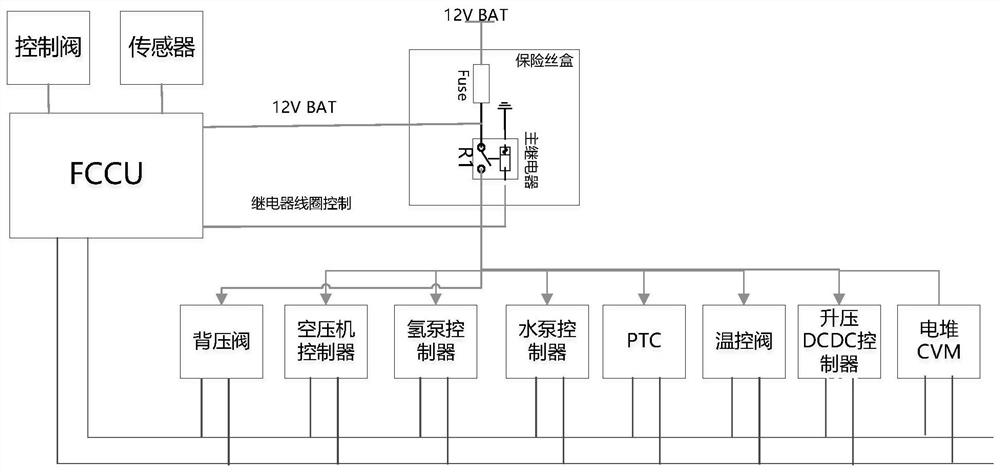

[0055] The fuel-electric system FCS 2 includes fuel cell controller FCCU 2.1, boost DCDC 2.2, FCS air compressor 2.3, FCS water pump 2.4, FCS hydrogen pump 2.5, FCS PTC 2.6, FCS fan 2.7, temperature control valve, back pressure valve, sensor Wait.

[0056] The vehicle's all-in-one controller 6 integrates 12V DCDC 6.1, 24V DCDC 6.2, drive motor controller MCU 6.3, high-voltage power distribution module, pre-charging circuit, relay (see KM3, KM5, KM6, KM8~10 in the figure), etc. .

[0057] The power battery system ...

Embodiment 2

[0066] Based on the full-power electric-electric hybrid fuel cell vehicle provided in Embodiment 1, this embodiment provides a power-off control method based on the full-power electric-electric hybrid fuel cell vehicle. The power-off control method includes a normal shutdown power-off process, a safety fault power-off process, and a normal fault power-off process, which will be described in detail below.

[0067] like Figure 4 As shown, the normal shutdown and power-off process includes the following steps:

[0068] S1: The normal power-off command of the vehicle is judged by the driver's driving intention. The vehicle controller VCU 1 recognizes whether the vehicle is powered off by receiving the keyless system PEPS signal and the gear position signal. When the driver presses the start button to enter the off gear, start the process of shutting down the fuel system (steps S3-S7) and the process of powering off the vehicle system (power battery system 4, drive motor 5, high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com