Material box cleaning and conveying equipment for food safety production

A technology for food safety and conveying equipment, which is applied to cleaning devices, transportation and packaging, conveyor objects, etc. The effect of low friction and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

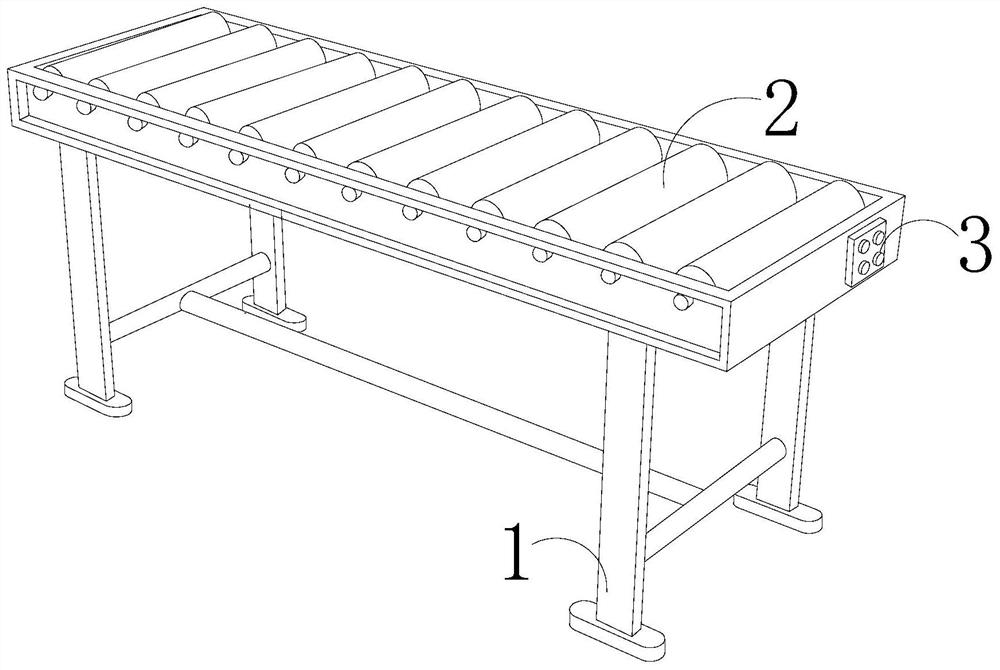

[0029] as attached figure 1 To attach Image 6 Shown:

[0030] The invention provides a material box cleaning and transmission equipment for food safety production, the structure of which includes a frame 1, a conveyor 2, and a controller 3, the bottom surface of the conveyor 2 is welded to the top of the frame 1, and the controller 3. The left side is fixed on the surface of the right end of the conveyor 2.

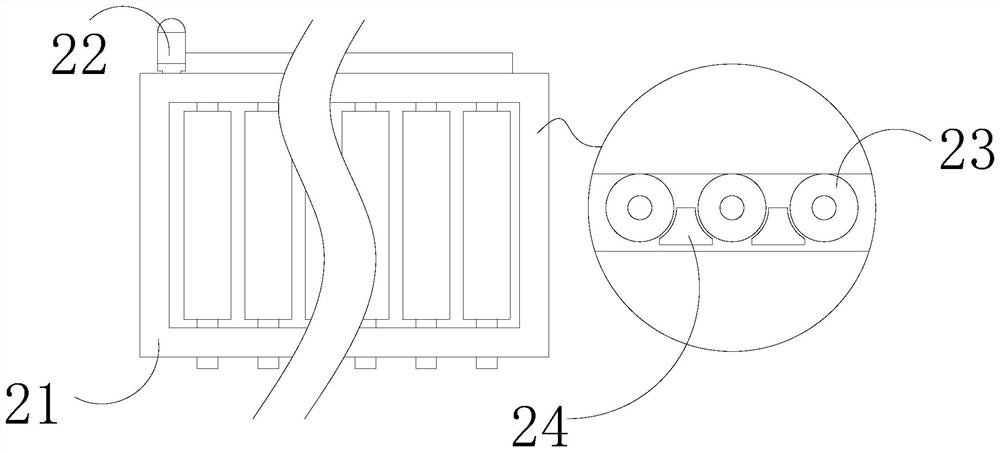

[0031] The conveyor 2 includes a body 21, a motor 22, a roller 23, and a cleaning mechanism 24. The motor 22 is arranged on the upper surface of the body 21, and the upper and lower ends of the roller 23 are respectively installed inside the body 21, and the upper end is movably matched with the motor 22. , the clearing mechanism 24 is located at the bottom between adjacent rollers 23 .

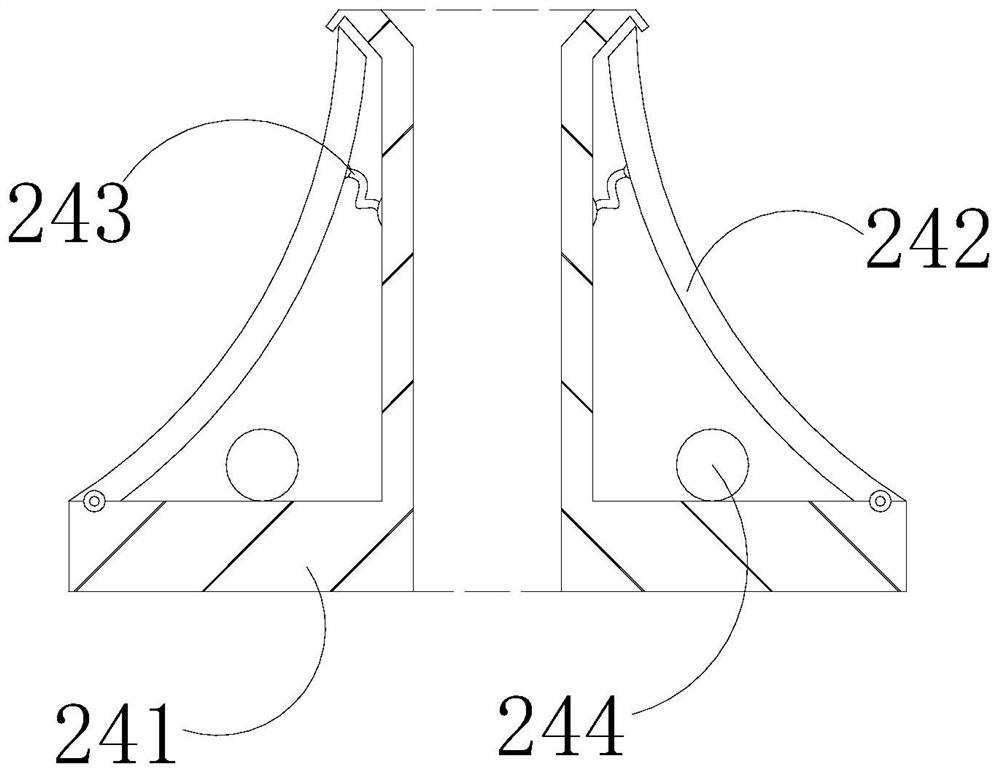

[0032] Wherein, the clearing mechanism 24 includes a support frame 241, a clearing plate 242, a push bar 243, and a push ball 244. The two ends are respectively connected between th...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] Wherein, the support frame 241 includes a frame body 41a, a drainage groove 41b, a movable cavity 41c, and a movable rod 41d, the drainage groove 41b runs through the middle surface of the upper and lower ends of the frame body 41a, and the movable cavity 41c is arranged at the inner bottom of the frame body 41a The middle part of the movable rod 41d is placed inside the movable cavity 41c, and the two ends are located outside the movable rod 41d. There are four movable rods 41d in total, which can increase the supporting force of the movable rod 41d to the support frame 241 and maintain the support The racks 241 are on the same horizontal plane.

[0041] Wherein, the movable rod 41d includes a bouncing ball d1, a strut d2, and a connecting bar d3, the inner end of the strut d2 is integrated with the middle surfaces of the left and right sides of the bouncing ball d1, and the inner end of the connecting bar d3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com