Dewatering well and dewatering construction method

A technology for dewatering wells and well bodies, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as soil excavation and foundation pit support restrictions, affecting construction efficiency, etc. , to achieve the effect of reducing the number of well points and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The embodiment of the present application discloses a dewatering well.

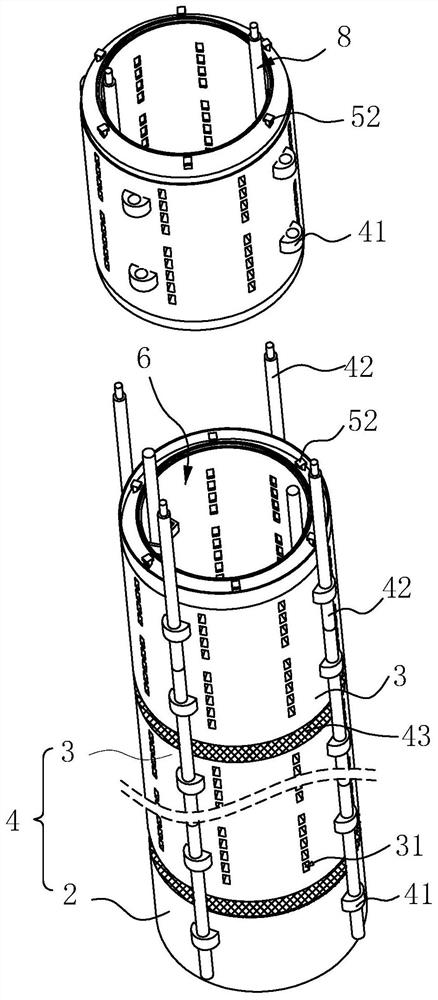

[0073] refer to figure 1 , the dewatering well includes at least one well body, and all the well bodies are connected and installed at the same well point.

[0074] In this embodiment, there is only one well body, and the well body includes at least three well body pipes 4, of which the lowermost one well body pipe 4 is a sedimentation pipe 2 installed in a confined aquifer 12; all other well body pipes 4 The filter pipe 3 runs through the submerged aquifer 11 , the aquifer 13 and the confined aquifer 12 .

[0075] refer to figure 1 , the bottom wall of the sedimentation tube 2 is sealed, and the opening faces upward. The water filter pipe 3 is a through pipe connected up and down, and the inner diameter of the water filter pipe 3 is consistent with that of the sedimentation pipe 2 .

[0076] refer to figure 2 , each well body pipe 4 is provided with a collar 41 , and an outer connecting rod ...

Embodiment 2

[0103] The application discloses a precipitation well.

[0104] refer to Figure 7 , based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that the structure of the control mechanism 7 is different.

[0105] refer to Figure 4 , Figure 7 , in this embodiment, the push ring 71 is provided with a notch 72 for the connecting assembly 8 to snap into the push ring 71 along a direction perpendicular to the axial direction of the push ring 71 .

[0106] The upper end of the fixing rod 81 can extend to the same horizontal position as the push ring 7 , and penetrate into the push ring 71 through the notch 72 . The inner wall of the push ring 71 has a rotation range for the fixed rod 81 to rotate axially around the water filter pipe 3 to cover or communicate with the water filter hole 31 , and the rotation range corresponds to the disassembly arc.

[0107] The notch 72 can be located on the side of the push ring 71 away from the inner wall of the water f...

Embodiment 3

[0112] The application discloses a precipitation well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com