Treatment method and system for designing liquefied gas tank cabin, equipment and medium

A technology of liquefied gas and processing methods, applied in image data processing, electrical digital data processing, computer-aided design, etc., can solve the problems of high labor cost and time cost, achieve multiple options, save time cost and labor cost, and constrain preferred effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1

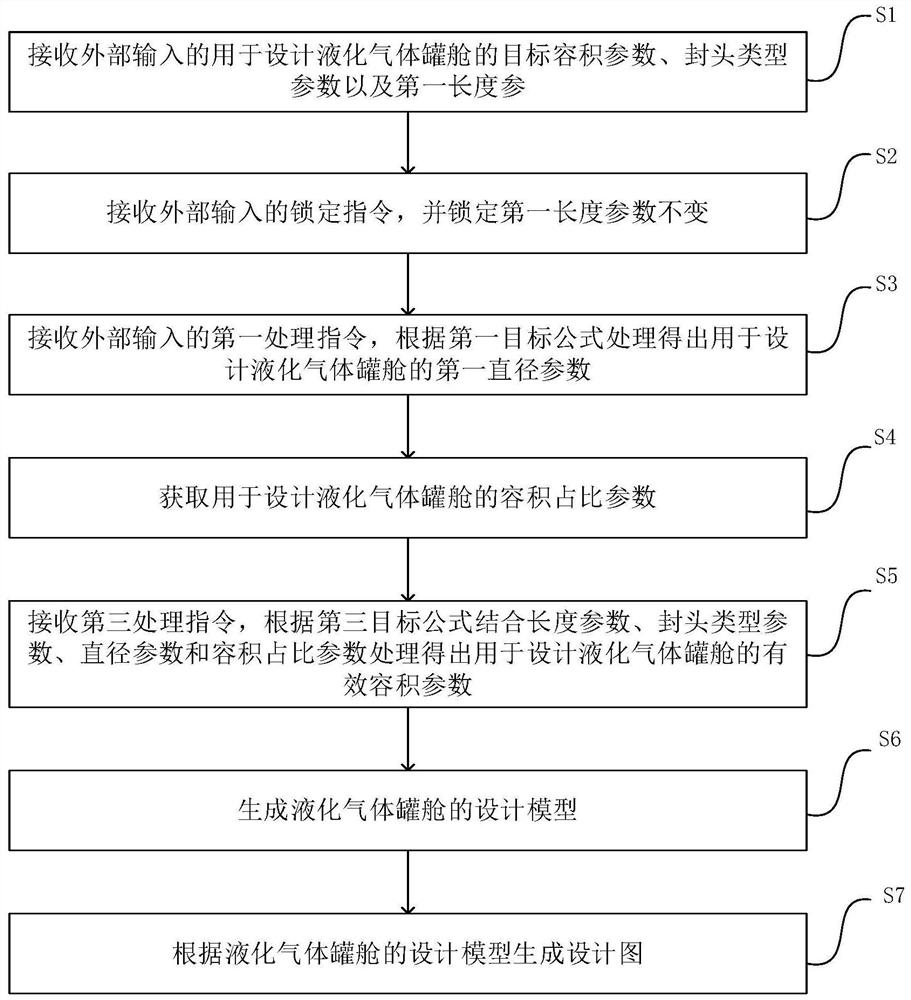

[0055] This embodiment provides a method of processing when designing a liquefied gas tank, see figure 1 , Including the following steps:

[0056] S1, receives the external input for designing the target volume parameters, the head type parameters, and the first length parameter of the liquefied gas canbuli.

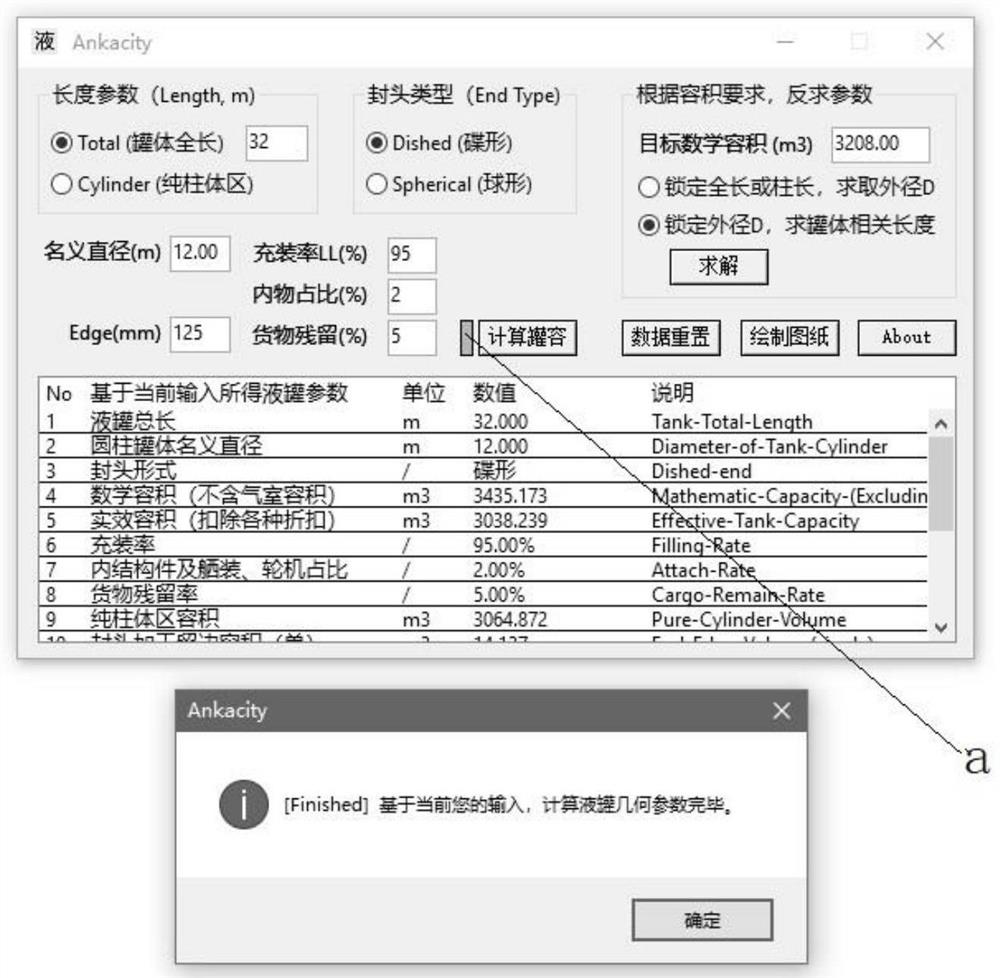

[0057] In this embodiment, figure 2 It is an operational interface diagram of the treatment method when designing the liquefied gas tank compartment, such as figure 2 As shown, when designing the liquefied gas tank, the user needs to process parameters for designing the liquefied gas tank, and the user can input target volume parameters (ie, the target mathematical volume in the figure), the head type parameters and the first One length parameter (i.e., the tank full length parameter), the head type parameter preferably includes the disc type head parameters and spherical head parameters in this embodiment, and the two parameters are commonly used in the shi...

Example Embodiment

[0078] Example 2

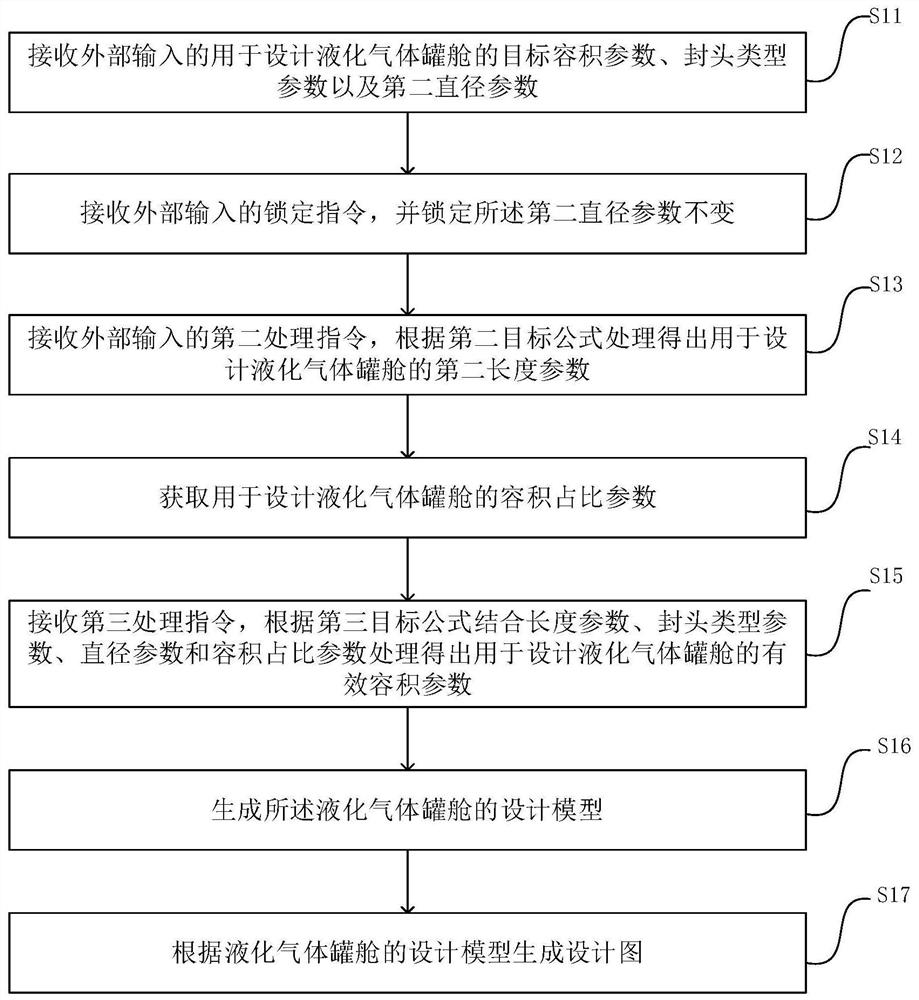

[0079] This embodiment provides a method of processing when designing a liquefied gas tank, see image 3 , Including the following steps:

[0080] S11, receives the external input for designing the target volume parameters, the head type parameters, and the second diameter parameters of the liquefied gas canbits.

[0081] figure 2 It is an operational interface diagram of the treatment method when designing the liquefied gas tank compartment, such as figure 2 As shown, when designing the liquefied gas tank, the user needs to process parameters for designing the liquefied gas tank, and the user can input target volume parameters (ie, the target mathematical volume in the figure), the head type parameters and the first Diameter parameters (ie, nominal diameter parameters in the figure), the head type parameter preferably includes disc type head parameters and spherical head parameters in this embodiment, which are commonly used in the current ship field, sealing T...

Example Embodiment

[0103] Example 3

[0104] The present embodiment provides a processing system in the design of the liquefied gas tank compartment, see Figure 4 The processing system comprising:

[0105] A receiving module, a receiving module configured to receive a certain volume of external input parameters for designing a liquefied gas tank compartment, a first head type parameter and a length parameter.

[0106] The receiving module receives the external input 1 is preferably a user input, the user needs to design a liquefied gas tank compartment, when the user gives an estimated volume, i.e. the volume of target parameters, the user can input a target volume parameter, and select a liquefied gas tank compartment design head type parameter needed, head type parameter in the present preferred embodiment includes a dish head and spherical head, head type parameter may be set according to actual needs, which is not defined, the user inputs a target volume parameters after, the corresponding need ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap