Automatic clamping and centering rubber tapping machine with incongruous crank

An automatic clamping and cranking technology, which is applied in agriculture, forestry, application, etc., can solve the problems of high requirements for rubber tapping workers, high working intensity and poor working environment, etc., and achieves stable tapping movement, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

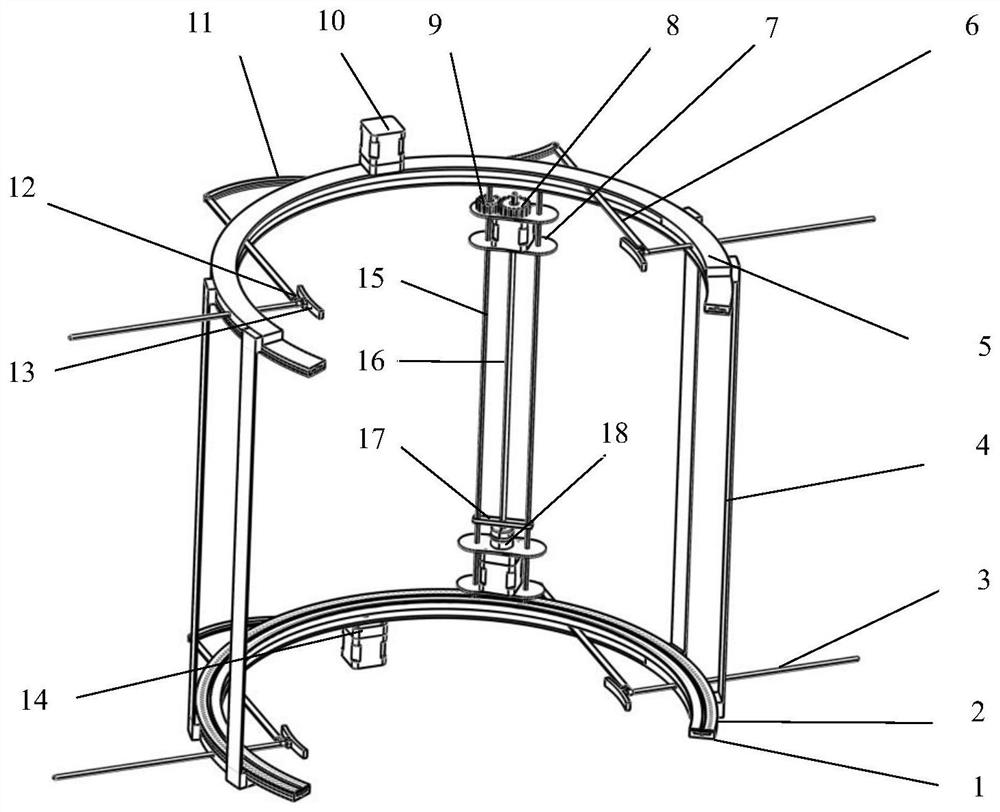

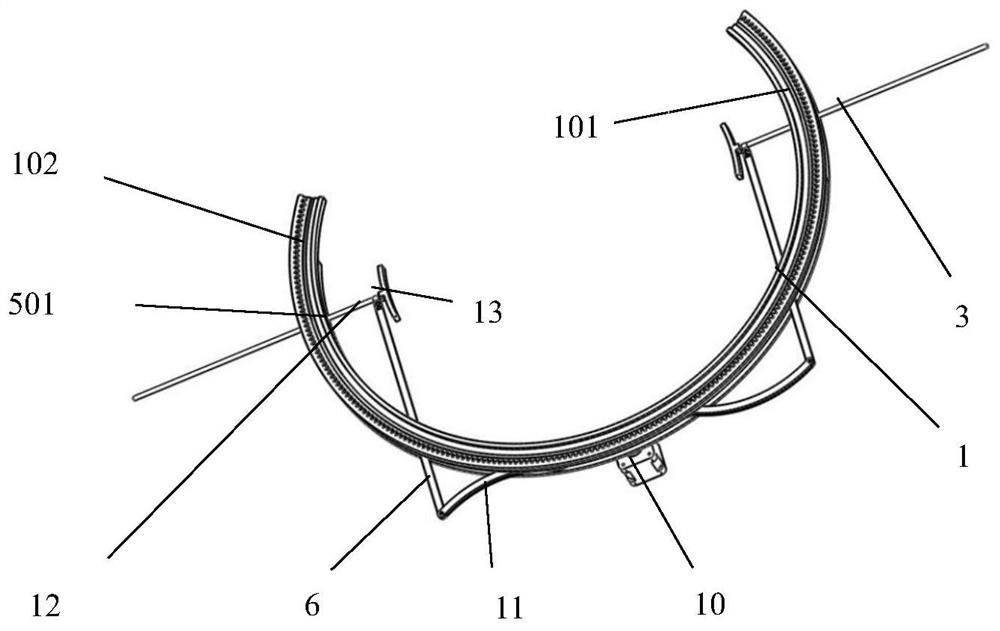

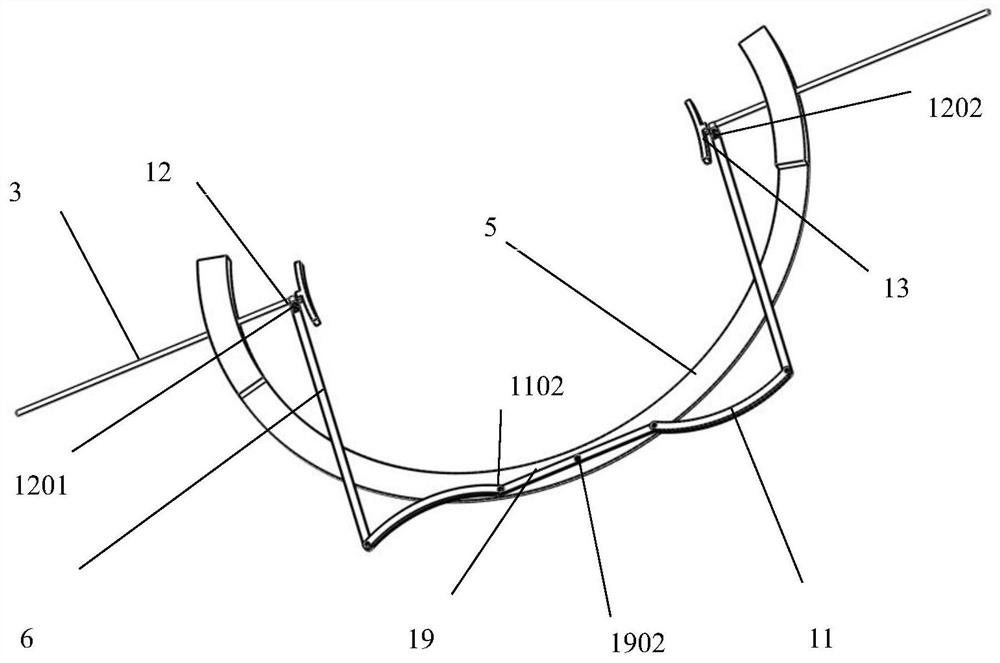

[0040] The examples are described in detail below with reference to the accompanying drawings.

[0041] Hereinafter, specific configuration and operation of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0042] like figure 1 Shown, the present invention is different automatic centering of clamping the crank tapping machine includes a clamping means, moving means and rack and pinion circumferential axial movement of the tool means; said gripping means comprises gripping means and the lower gripping means, by connecting in this order from the support plate 4; circular movement of the rack and pinion means 15 and the optical axis passing through the circular motion of the gear 20 is mounted on the inside of the carrier 1, through the circular motion of the optical axis 15 installed at both ends of the gear 20 a rack meshing with the semicircular gears on a frame 102, the circular motion of the gear 20 to provide rotational tor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap