A process for producing special-shaped double-layer metal vacuum insulation cups

A double-layer metal, vacuum insulation technology, applied in the direction of drinking water containers, etc., can solve the problem of single shape and style, and it is difficult to meet the needs of diverse shapes and styles of thermos cups. The effect of diverse needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the embodiments given in the accompanying drawings.

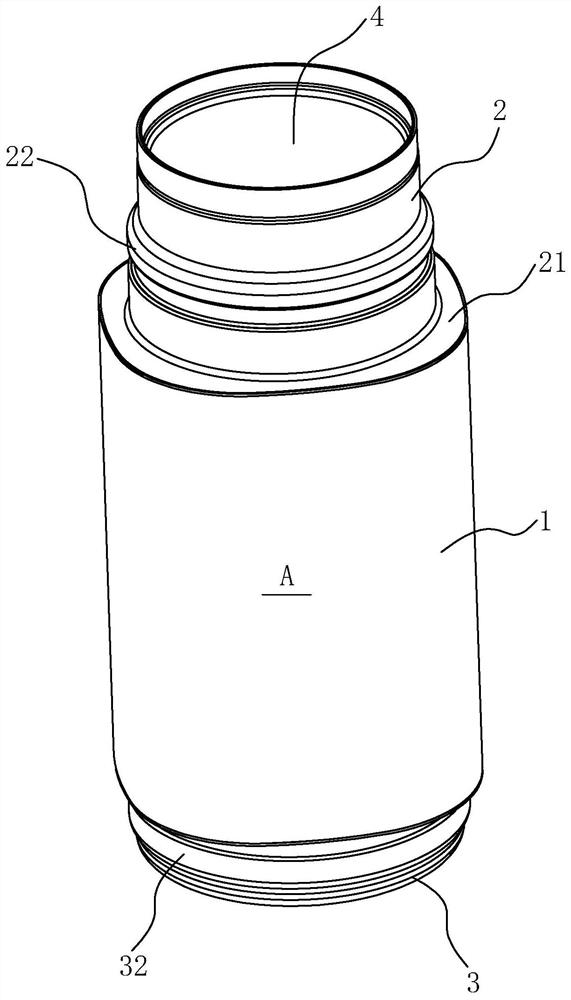

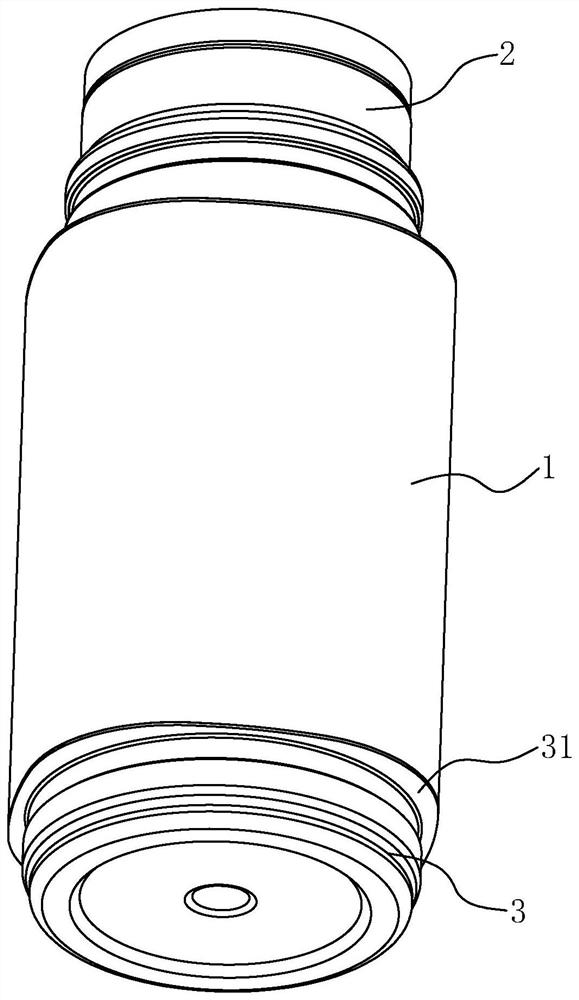

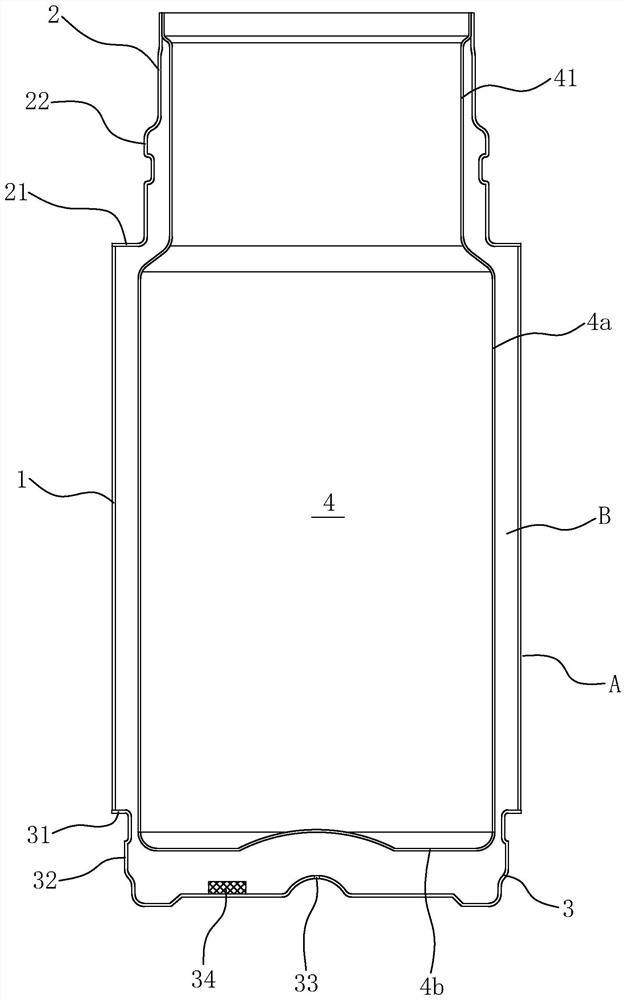

[0028] like Figure 1 to Figure 5 As shown, a process for producing a special-shaped double-layer metal vacuum thermos cup described in this embodiment includes the following steps:

[0029] (1) Make the cup shell body 1, the cup shell mouth 2, the cup shell bottom 3 and the cup liner 4 respectively, wherein, the cup shell shell 1 is a special-shaped metal shell with non-circular and open upper and lower ends. Structure, the cup shell mouth 2 is a circular metal shell structure with both upper and lower ends open, the outer side of the lower end of the cup shell mouth 2 has a first annular step 21 that matches the shape of the cup shell body 1, and the cup shell bottom 3 It is a circular metal shell structure with an open upper end and a closed lower end. The outer side of the upper end of the bottom 3 of the cup shell has a second ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com