Polymethyl methacrylate/polyvinylidene fluoride composite material as well as preparation method and application thereof

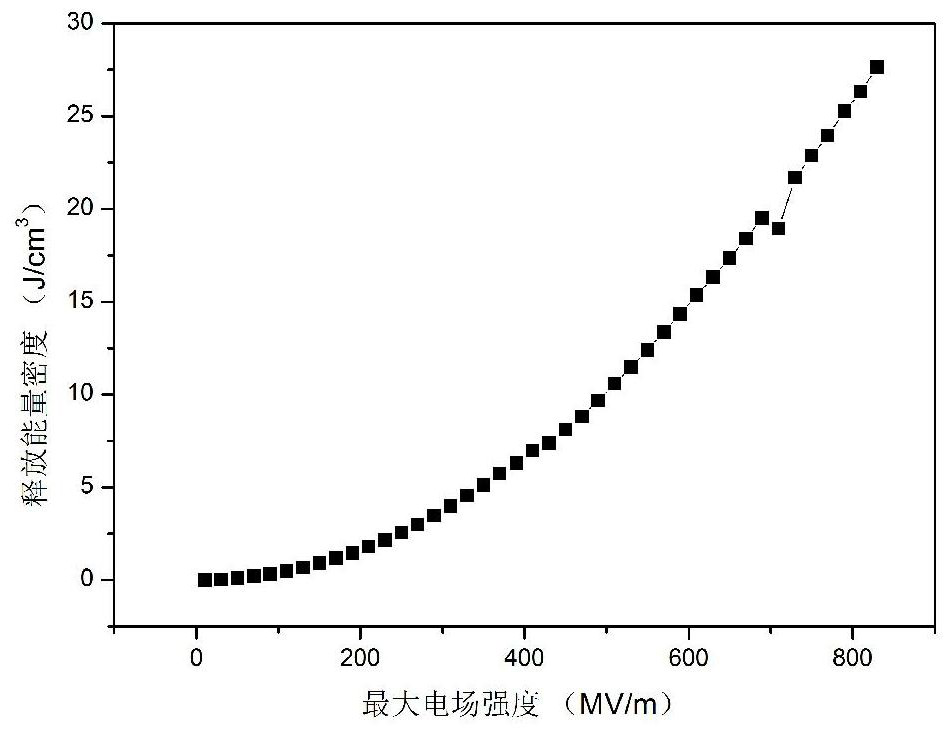

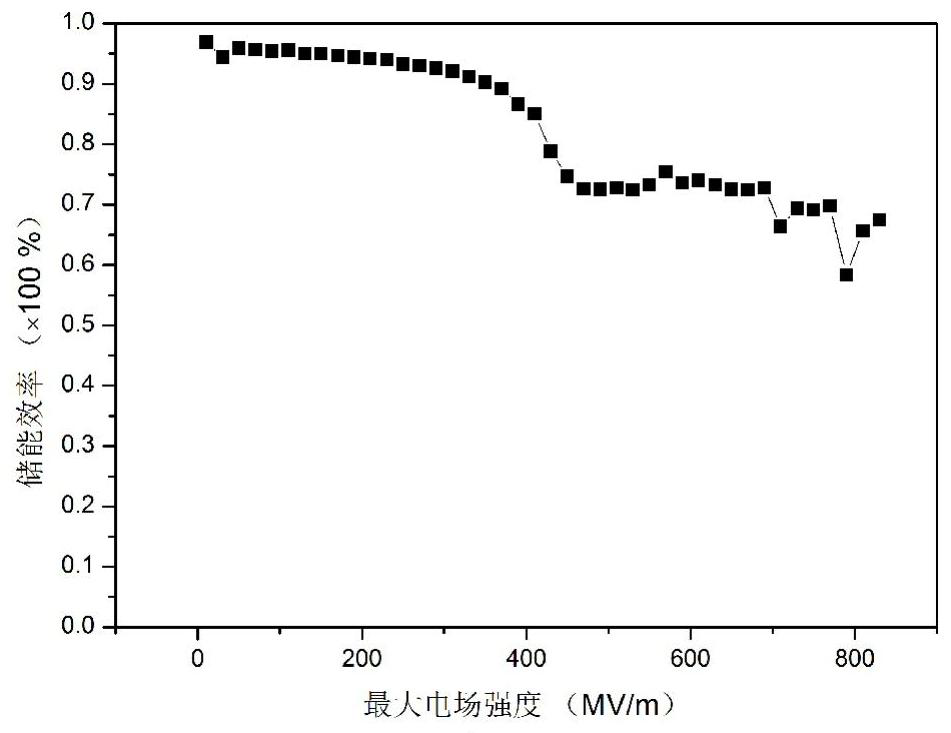

A technology of polymethyl methacrylate and polyvinylidene fluoride, which is applied in the field of polymethyl methacrylate/polyvinylidene fluoride composite material and its preparation, can solve the problem of low energy storage efficiency and energy density of composite materials, and energy storage problems. Poor performance and other problems, to achieve the effect of reducing residual polarization, improving energy storage characteristics, and increasing the maximum electrical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a preparation method of polymethyl methacrylate / polyvinylidene fluoride composite material, comprising the steps of:

[0045] (1) polymethyl methacrylate and organic solvent are mixed to obtain sol A;

[0046] (2) mixing polyvinylidene fluoride with an organic solvent to obtain sol B;

[0047] (3) mixing the sol B obtained in the step (2) with the sol A obtained in the step (1) to obtain a blended sol;

[0048] (4) Film-forming treatment is carried out after the blended sol obtained in the step (3) is coated to obtain a polymethyl methacrylate / polyvinylidene fluoride composite material;

[0049] The steps (1) and (2) are not in sequence.

[0050] The present invention mixes polymethyl methacrylate and an organic solvent to obtain sol A.

[0051] In the present invention, the organic solvent preferably includes N,N-dimethylformamide or N,N-dimethylacetamide.

[0052] In the present invention, the mass of the polymethyl methacrylate and the volu...

Embodiment 1

[0079] (1) Add polymethyl methacrylate particles to N, N-dimethylformamide, magnetic stirring makes polymethyl methacrylate dissolve completely, obtains sol A, wherein the quality of polymethyl methacrylate and The volume ratio of N,N-dimethylformamide is 1g:6.7mL, the stirring rate is 950rpm, the stirring time is 2.5h, and the stirring temperature is 30°C;

[0080] (2) Add polyvinylidene fluoride powder to N, N-dimethylformamide, and magnetically stir to completely dissolve polyvinylidene fluoride to obtain sol B, wherein the quality of polyvinylidene fluoride and N, N-di The volume ratio of methylformamide is 1g:5mL, the stirring rate is 950rpm, the stirring time is 1h, the stirring temperature is 25°C, and the addition rate of polyvinylidene fluoride is 0.03g / min;

[0081] (3) Add sol B to sol A, stir magnetically for 7 hours at a stirring rate of 950rpm, and let it stand for 12 hours to obtain a blended sol, wherein the addition rate of sol B is 0.5mL / min, and the polyform...

Embodiment 2

[0092] (1) Add polymethyl methacrylate particles to N, N-dimethylformamide, magnetic stirring makes polymethyl methacrylate dissolve completely, obtains sol A, wherein the quality of polymethyl methacrylate and The volume ratio of N,N-dimethylformamide is 1g:6.7mL, the stirring rate is 950rpm, the stirring time is 2.5h, and the stirring temperature is 30°C;

[0093] (2) Add polyvinylidene fluoride powder to N, N-dimethylformamide, and magnetically stir to completely dissolve polyvinylidene fluoride to obtain sol B, wherein the quality of polyvinylidene fluoride and N, N-di The volume ratio of methylformamide is 1g:5mL, the stirring rate is 950rpm, the stirring time is 1h, the stirring temperature is 25°C, and the addition rate of polyvinylidene fluoride is 0.03g / min;

[0094] (3) Add sol B to sol A, stir magnetically for 7 hours at a stirring rate of 950rpm, and let it stand for 12 hours to obtain a blended sol, wherein the addition rate of sol B is 0.5mL / min, and the polyform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

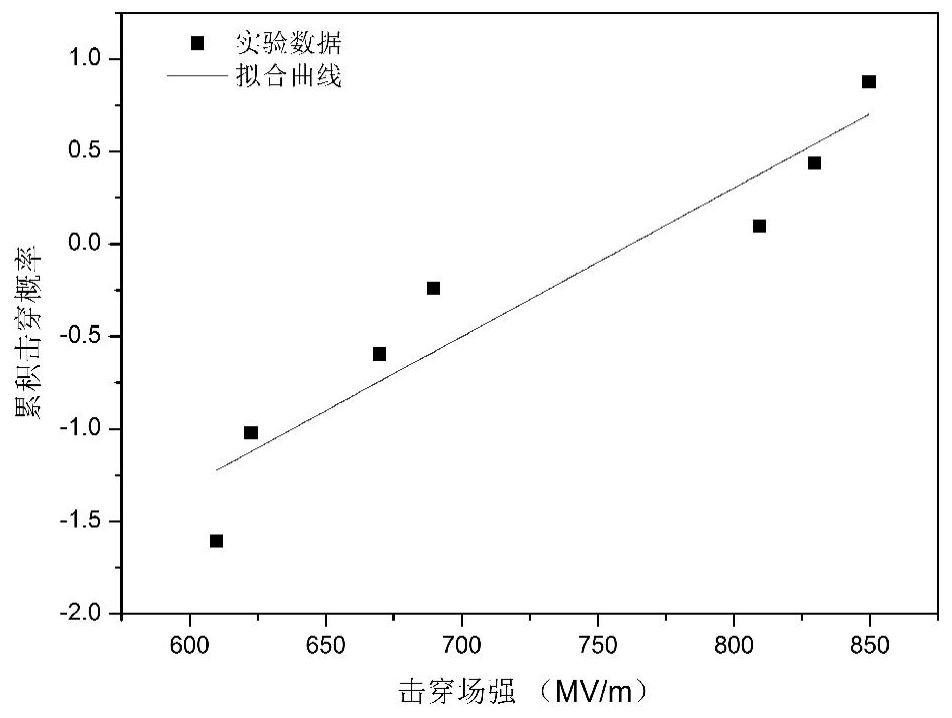

| Breakdown field strength | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com